13

en

0698-401 MD1xL / MD2xL - 08/2020

6. Maintenance and servicing

If the compressed air motor is missing the required power, check the following points:

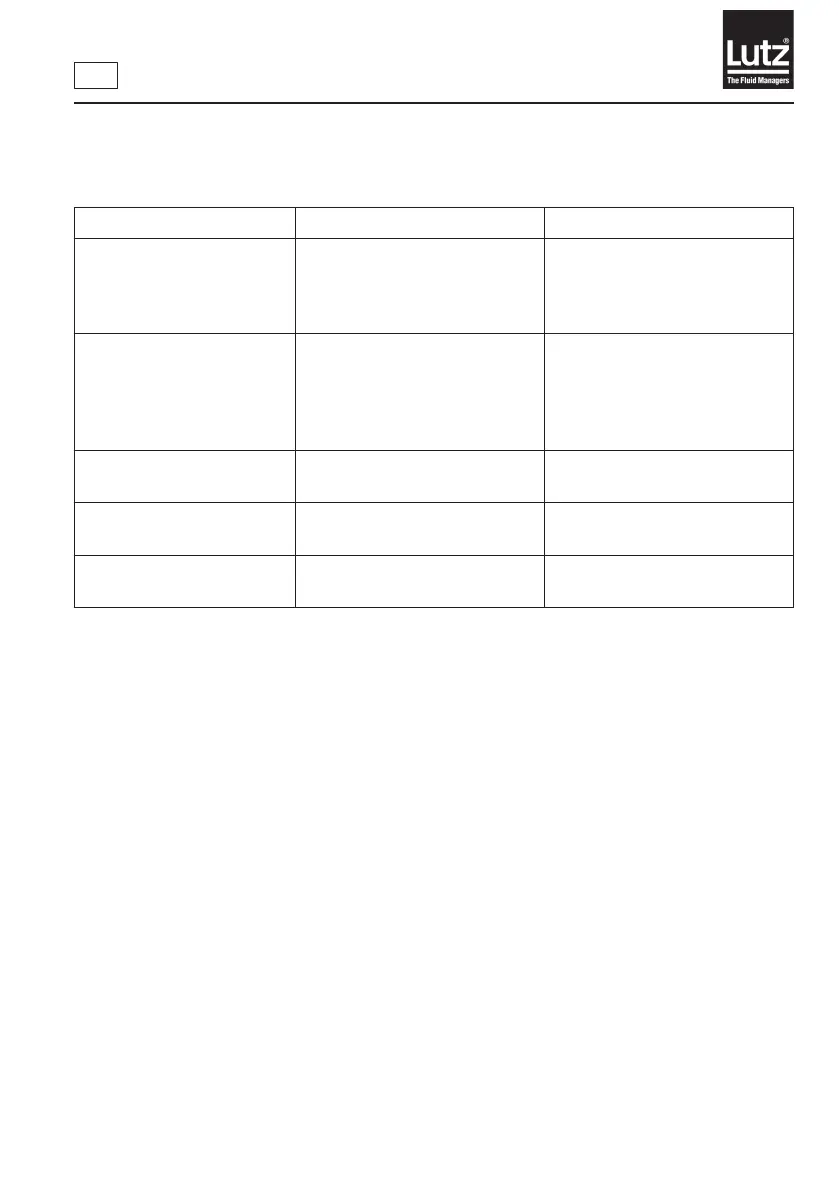

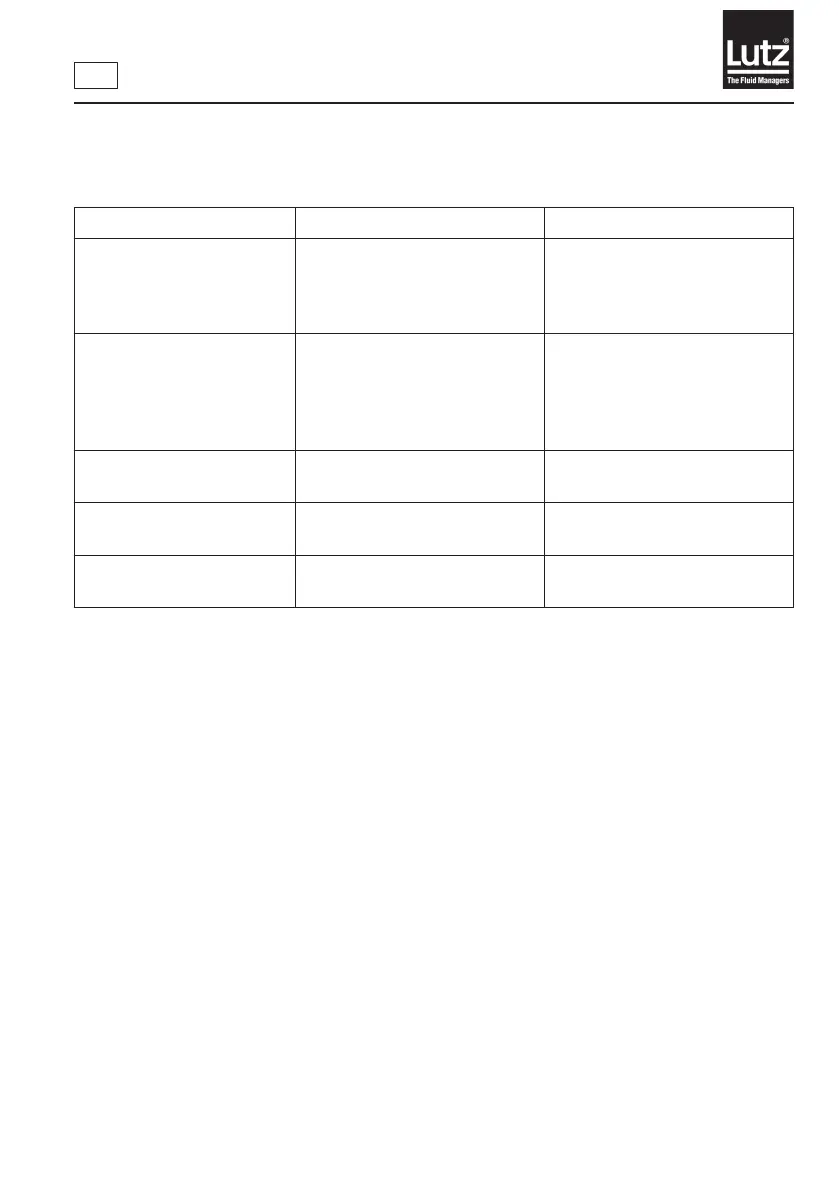

Fault Cause Remedy

Airpressurenotsucient

(6bar/87psi)

• Compressed air line is leaky

• Pressure losses

• Seal or replace the compressed

air line

• Enlarge the cross-section of the

compressed air line

Airpressureuctuating • Compressed air line is leaky

•Compressedairline,mueror

airlterblocked

• Error during generation of

compressed air

• Seal or replace the compressed

air line

• Clean compressed air line,

muerorairlter

• Check air compressor

Airlteronmaintenanceunit

is dirty or blocked

• Impurities in compressed air •Cleaningtheairlter

Lack of oil in the compressed

air system

• Oiler impure or damaged • Clean, repair or replace oiler

Muerblocked • Impurities in compressed air

• Dust in the environment

•Cleanmuer

If none of the above defects is detected, the compressed air motor must be repaired.

7. Repairs

►RepairsshouldonlybemadebythemanufacturerorauthorizedLutzdealers.

►OnlyuseoriginalLutzPumpenspareparts.Ifothersparepartsareused,liabilityonthepartofLutz

Pumpen is obsolete.

8. Disposal

Dispose of the motor according to the locally applicable regulations.

Loading...

Loading...