11

en

0698-401 MD1xL / MD2xL - 08/2020

• Install the maintenance unit with an air connection of at least G 1/4 in the immediate vicinity of the

compressedairmotor(1).Usearesin-freeandacid-freemineraloilwithaviscosityof20to30mm²/s

intheoiler(3).Theoilconsumptionshouldbe1dropperminuteasaminimum.

• Theairlter(3)requiresregularmaintenanceduringwhichthetrappedcondensationwaterisdrained

andthelteriscleaned.

• Thecompressedairmotorwillachievemaximumperformanceat6bar(87psi).Thepressureinthe

pneumaticsystemexceeding6bar,apressureregulator(3)mustbeinstalled.Adjustmentofthepressure

regulator(3)mustbeeectedwiththemotorrunning.

• Installanairhose(2)of13mminsidediameterbetweenmaintenanceunitandcompressedairmotor

tominimizethepressurelosses.

• Use a stop valve in the pressure line in order to connect and disconnect the motor without pressure.

• Note the resulting pressure loss when using quick-action couplings.

Recommendation for compressed air supply

• TheclassicationofthecompressedairqualitycanbetakenfromISO8573-1:2010.

• Standard values of compressed air quality are e.g. to be found in VDMA 15390-1: 2014-12.

• For lubricated air, a minimum compressed air quality by ISO 8573-1: 2010 [-: 4: 4] is recommended.

• For non lubricated air, a minimum compressed air quality by ISO 8573-1: 2010 [6 3: 3] is recommended.

• Excessivewatercontentinthecompressedaircancausefreezingofthewaterparticles.Thismaybethe

causefordamagingthevanesorcloggingthemuer,whichmayaecttheperformanceofthemotor.

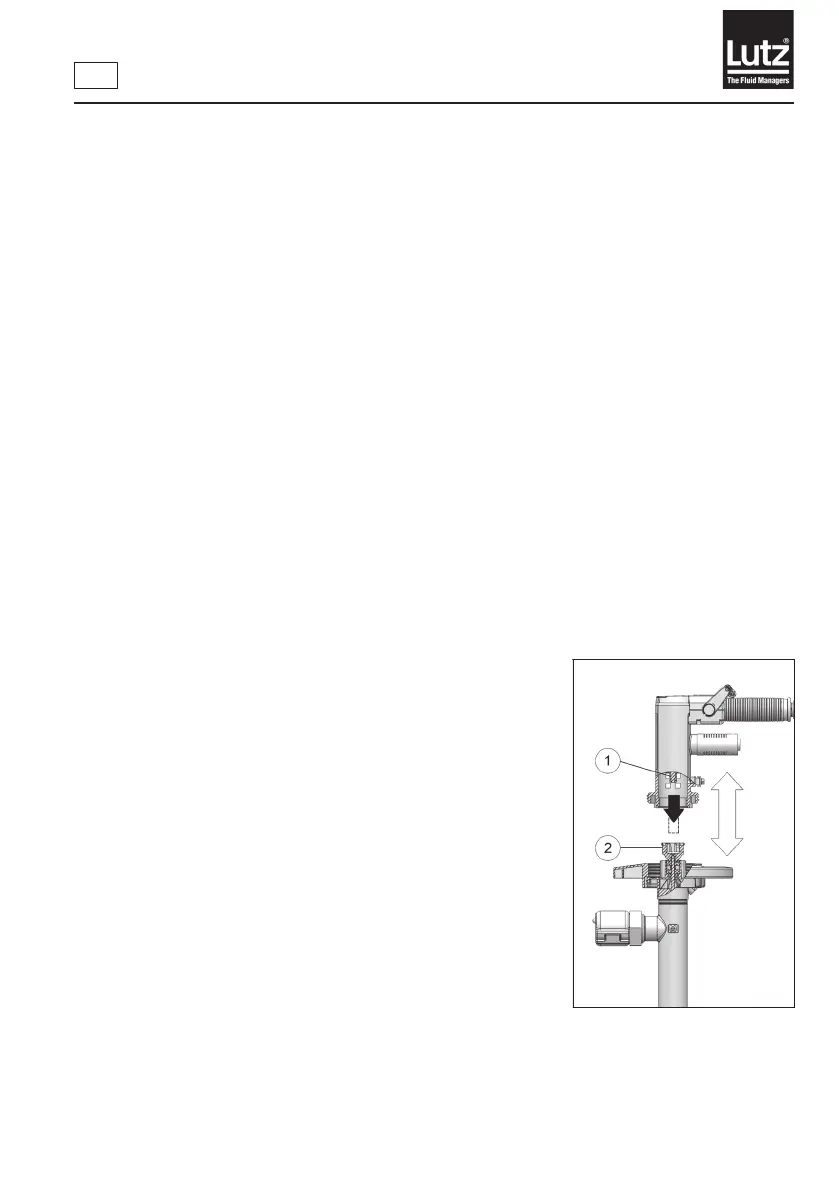

4.2 Assembly of pump tube to the motor

3Motorisswitchedo

► Connect the motor with the pump tube.

► Turn the motor slightly to ensure that the driver (→Fig.2,Item1)

engages in the coupling (→Fig.2,Item2).

► Firmly connect the motor and pump tube by means of the

handwheel(right-handthread)(→Fig.2).

Fig. 2

Loading...

Loading...