E. Testing

1. Heat pump checks before use

a. The air inlets and outlets are free of any debris and are not obstructed.

b. Refrigeration pipes or components are not installed in a corrosive environment.

c. Check electric wiring connections are tight and adhere to the electrical schematic

d. Check for water leaks around the machine and all new water connections

2. Refrigerant leak detection

a. Leak testing is prohibited in enclosed areas

b. Any source of ignition is prohibited during leak checks.

c. Leak detection fluids can be used with most refrigerants but the use of products containing

chlorine should be avoided as the chlorine may react with the refrigerant and corrode the

copper pipe.

d. Vacuum the machine completely before welding. Welding should only be carried out by a

professional person in a service center.

e. Please stop immediately if a gas leak occurs, and contact your local service center.

3. Trial Run

a. The circulation pump must start before the heat pump and stop after the heat pump to avoid any

damage occurring to the machine.

b. In order to protect the heat pump, the machine is equipped with a time lag start function, the fan

will run 1 minute earlier than the compressor when starting the machine, and it will stop running

1 minute later than the compressor when power off the machine.

c. After the heat pump starts, check for any abnormal noises from the machine.

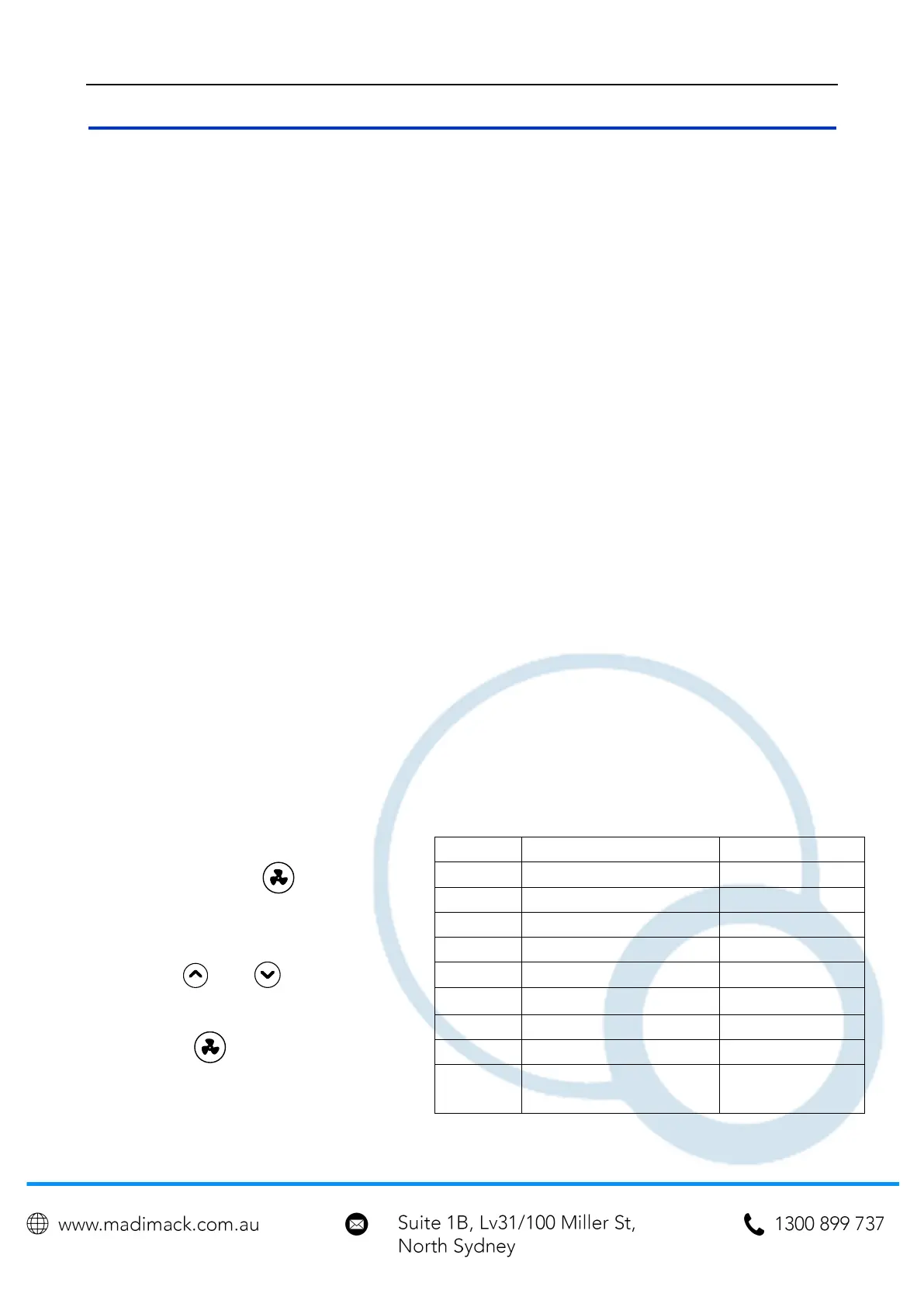

Running status codes and corresponding values

4. Running status check

a. Press and hold for 5 seconds, a

beep sound should be heard and it will

enter into running status mode

b. Use and to switch through

the different values

c. Press again to quit can running

status mode

Electronic expansion

valve opening

Loading...

Loading...