4

48-651 SIL Certified Safety Manual for E3 Modulevel

®

1.3 Determining Safety Integrity Level (SIL)

Safety Instrumented System designers using the

E3 MODULEVEL must verify their design per applicable

standards.

Three limits must be met to achieve a given SIL level:

1. The PFD

AVG

numbers for the entire Safety Instrumented

Function (SIF) must be calculated. Table 2 shows the rela-

tionship between the Safety Integrity Level (SIL) and the

Probability of Failure on Demand Average (PFD

AVG

).

2. Architecture constraints must be met for each subsystem.

Table 3 can be used to determine the achievable SIL as a

function of the Hardware Fault Tolerance (HFT) and the

Safe Failure Fraction (SFF) for each subsystem in a safety

system (Type B–complex components as per IEC 61508

Part 2) of which the level transmitter is just one component.

3. All products chosen for use in the SIF must meet the

requirements of IEC 61508 for the given SIL Capability

level or be justified based on proven in use data collected for

each job.

The exSILentia tool from exida is recommended for design

verification. This automatically checks all three limits and

displays the results for any given design. The E3 MOD-

ULEVEL is in the exSILentia database. This tool contains

all needed failure rate, failure mode, SIL Capability and

common cause data as well as suggested proof test methods.

2.0 Applicable Models

This manual is only applicable to the HART versions of

the E3 MODULEVEL transmitter shown in Table 1.

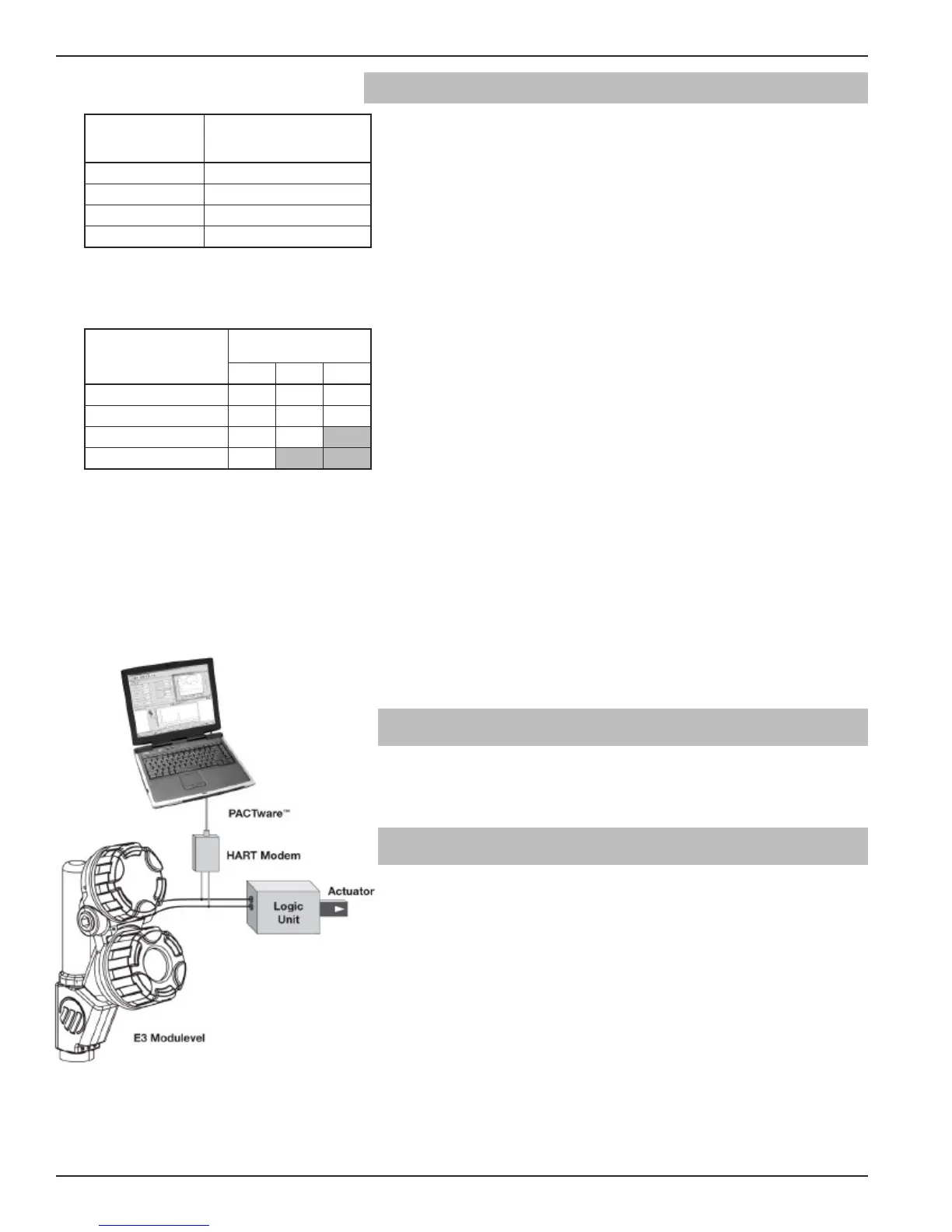

3.0 Level Measuring System

The diagram at left shows the structure of a typical measuring

system incorporating the E3 MODULEVEL transmitter.

This SIL 2/3 Certified device is only available with an ana-

log signal (4–20 mA) with HART communications; and,

the measurement signal used by the logic solver can be the

analog 4–20 mA signal proportional to the Level, Interface

Level or Density.

• For fault monitoring, the logic unit must recognize both

high alarms (≥ 21.5 mA) and low alarms (≤ 3.6 mA).

• If the logic solver loop uses intrinsic safety barriers, caution

must be taken to ensure the loop continues to operate

properly under the low alarm condition.

Figure 1

Typical System

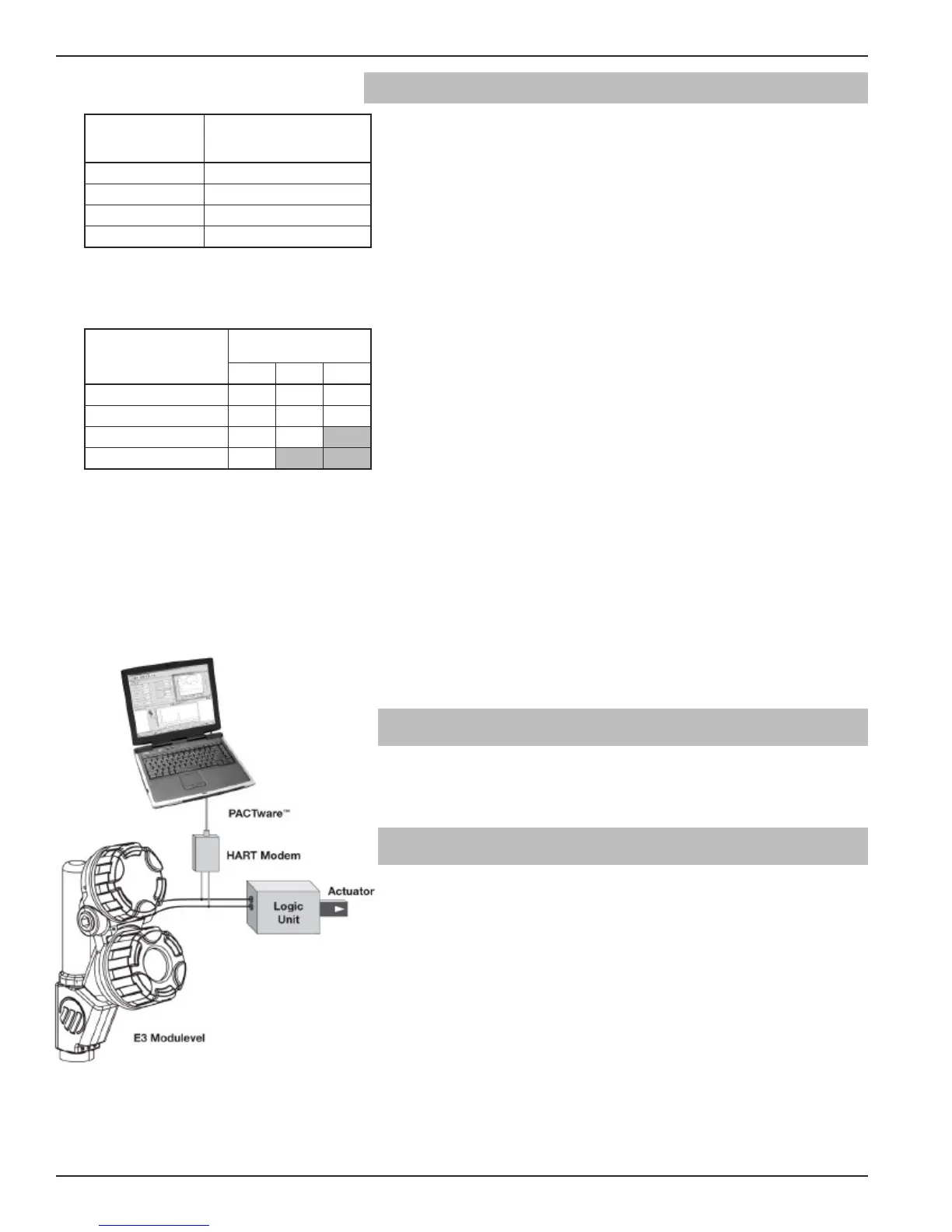

Table 3

Minimum hardware fault tolerance

Type B sensors, final elements and non-PE logic solvers

SFF

Hardware Fault

Tolerance (HFT)

0 1 2

None: <60%

N

ot

Allowed

SIL 1 SIL 2

Low: 60% to <90% SIL 1 SIL 2 SIL 3

Medium: 90% to <99% SIL 2 SIL 3

High: ≥99% SIL 3

Table 2

S

IL vs. PFDavg

Safety

Integrity Level

(SIL)

Target Average

probability of failure

on demand (PFDavg)

4 ≥10

-5

to <10

-4

3 ≥10

-4

to <10

-3

2 ≥10

-3

to <10

-2

1 ≥10

-2

to <10

-1

Loading...

Loading...