Do you have a question about the Magnetrol E3 Modulevel and is the answer not in the manual?

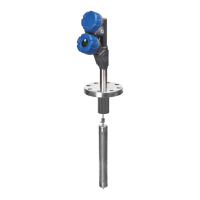

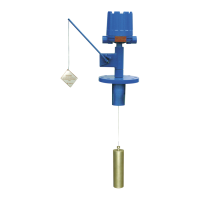

Introduction to the Liquid Level Displacer Transmitter.

How liquid level changes are detected via LVDT.

Capabilities for measuring interface levels and fluid density.

Cautionary notes regarding power and grounding.

Proper methods for grounding shield wires.

Requirements for hazardous area wiring and barriers.

Setting up and managing password security for configuration.

Configuring level units, specific gravity, temperature, and span points.

Setting HART poll address, loop mode, and trim values.

Performing loop tests and capturing 4mA/20mA points.

Factory settings; user enters operating temperature, wet calibration.

Setting level units, temperature, span points, offset, and damping.

Setting HART poll address, loop mode, and trim for interface.

Performing loop tests and capturing interface span points.

Factory calibrated; user enters operating temperature for density.

Setting operating temperature, span points, and damping for density.

Setting HART poll address, loop mode, and trim for density.

Setting 4mA for min S.G. and 20mA for max S.G.

Procedure for calibrating 4mA/0% and 20mA/100% levels.

Procedure for calibrating interface levels with displacer immersion.

Calibrating interface using water with specific gravity examples.

Using liquids with varying specific gravities for interface calibration.

Reviewing factory parameters, diagnostic messages, and runtime.

Steps for matching electronics or replacing parts with user calibration.

Detailed steps for capturing low and high calibration values.

Guide to diagnosing and resolving system issues based on symptoms.

Diagnosing and resolving 'SecFltHi', 'CoreDrop', 'PriFault' errors.

Procedure for safely removing and replacing the transmitter head.

Steps for replacing the LVDT and testing its winding resistance.

Information on ATEX, FM, FISCO, and SIL safety certifications.

| Brand | Magnetrol |

|---|---|

| Model | E3 Modulevel |

| Category | Measuring Instruments |

| Language | English |