19

MAINTENANCE

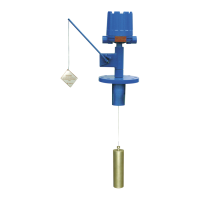

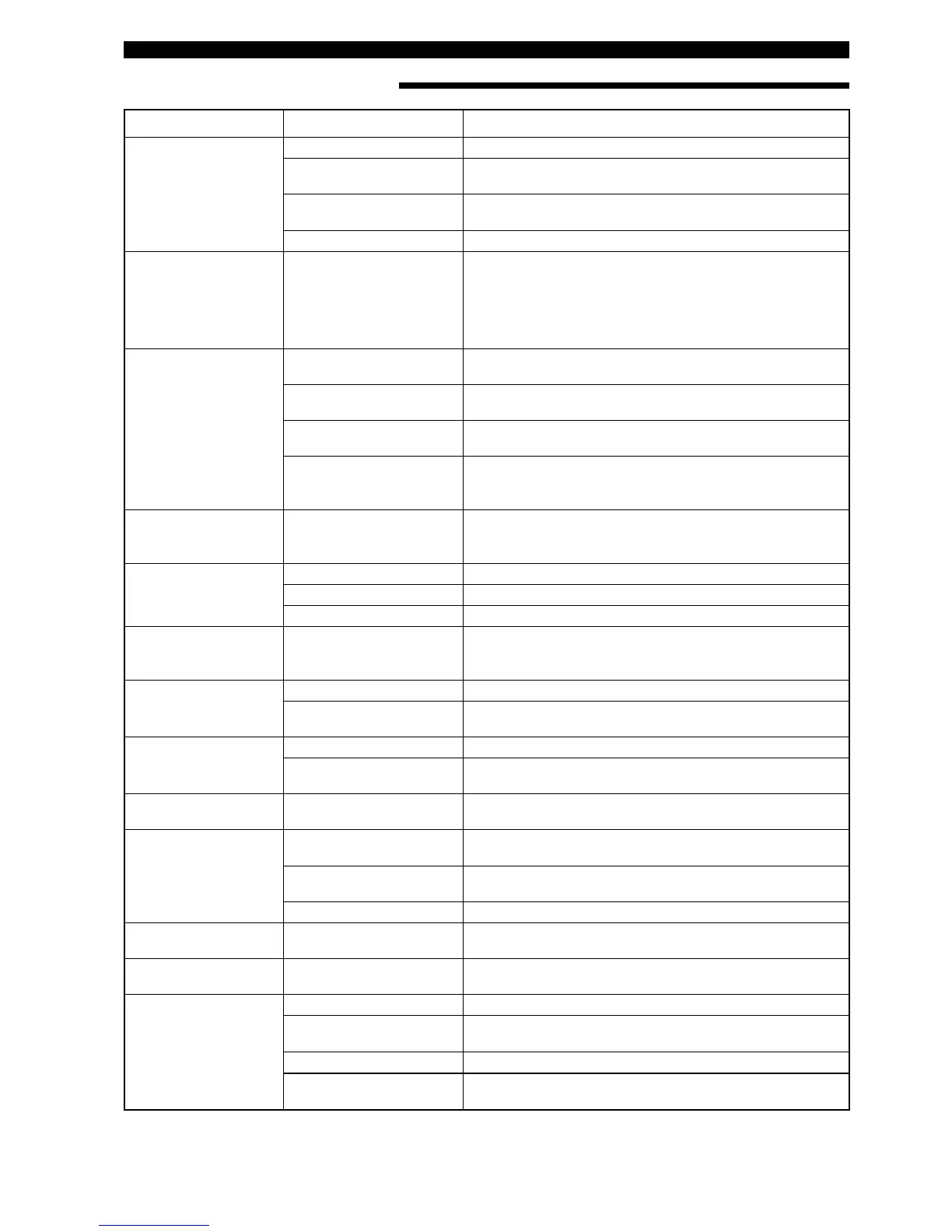

TROUBLESHOOTING SYSTEM PROBLEMS

S

ymptom

P

roblem

S

olution

No loop current. Power supply not turned on. Turn on power.

Insufficient source voltage. E3 requires a minimum of 11 VDC at the wiring board. Verify

supply voltage.

Improperly wired or

damaged wiring.

Check wiring and connections.

Defective electronics. Replace PC board assembly or wiring board as required.

L

EVEL, % OUTPUT and

LOOP values are all

inaccurate.

B

asic configuration data is

questionable.

V

erify Level Offset values.

If using factory calibration, verify that Process SG and

Operating Temperature values are accurate.

Verify/confirm that Model Parameters are accurate.

Confirm set points are as expected.

Transmitter does not

track level.

Model incompatible with

process liquid

Verify model in use is appropriate for process liquid SG.

Possible damage to unit. Check displacer, spring, stem and enclosing tube for damage.

Replace all damaged parts.

Possible material buildup Check displacer, spring, stem, enclosing tube and displacer for

buildup of process material. Clean any fouled parts.

Displacer, spring or stem

dragging on inside of

chamber, e-tube.

Verify proper and level installation (within 3 degrees of plumb in

all directions).

Level reading on display

is correct, but loop value

is stuck at 4 mA.

Invalid poll address. Set poll address to 0 if not using multi-drop.

LEVEL, % OUTPUT and

LOOP values fluctuate.

Liquid turbulence. Increase damping until output stabilizes or install stilling well.

Power supply unstable. Repair or replace power supply.

Electrical interference (RFI). Consult factory for assistance.

HART device only:

Handheld will only read

Universal Commands

Most current Device

Descriptors are not installed

in handheld.

Contact local HART service center for the latest DDs.

Cannot set high level to

20 mA

Incorrect power supply. Check power supply.

Excessive loop resistance Increase power supply voltage or decrease loop resistance

(max 620 ohms @ 24 VDC).

Loop current less than

4 mA

Liquid level less than 0%. No action required.

Supply voltage out of limits

at transmitter.

Adjust power supply or reduce loop resistance.

4 mA output does not

match display

4 mA may need to be

trimmed.

Use Trim 4 mA to adjust output to match display.

Loop current exceeds

20 mA

Liquid level greater than

100%.

No action required.

Supply voltage out of limits

at transmitter.

Adjust power supply or reduce loop resistance.

Wired incorrectly. Check power supply (+) and (-) for reverse wiring.

20 mA output does not

match display

20 mA may need to be

trimmed.

Use Trim 20 mA to adjust output to match display.

Output jumps quickly

over wide range

Bent stem impeding smooth

core movement

Review Status History for Surge event. Inspect stem and

replace if damaged.

Non-linear output. Excessive loop resistance. Increase power supply voltage or decrease loop resistance.

Displacer hanging up. Verify proper and level installation (within 3 degrees of plumb in

all directions.)

Bent stem. Check stem. Replace if damaged.

Possible material buildup Check displacer, spring, stem, enclosing tube and displacer for

buildup of process material. Clean any fouled parts.

Loading...

Loading...