7 ENGLISH

Before actual operation, drive a trial screw into your material or a piece of duplicate material to determine which

torque level is required for a particular application.

Thefollowingshowstheroughguideoftherelationshipbetweenthescrewsizeandgraduation.

Graduation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Machine screw M4 M5 M6

Wood

screw

Soft wood

(e.g. pine)

– ɸ3.5 x 22 ɸ4.1x 38 –

Hard wood

(e.g. lauan)

– ɸ3.5 x 22 ɸ4.1x 38 –

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Installing or removing driver bit/

drill bit

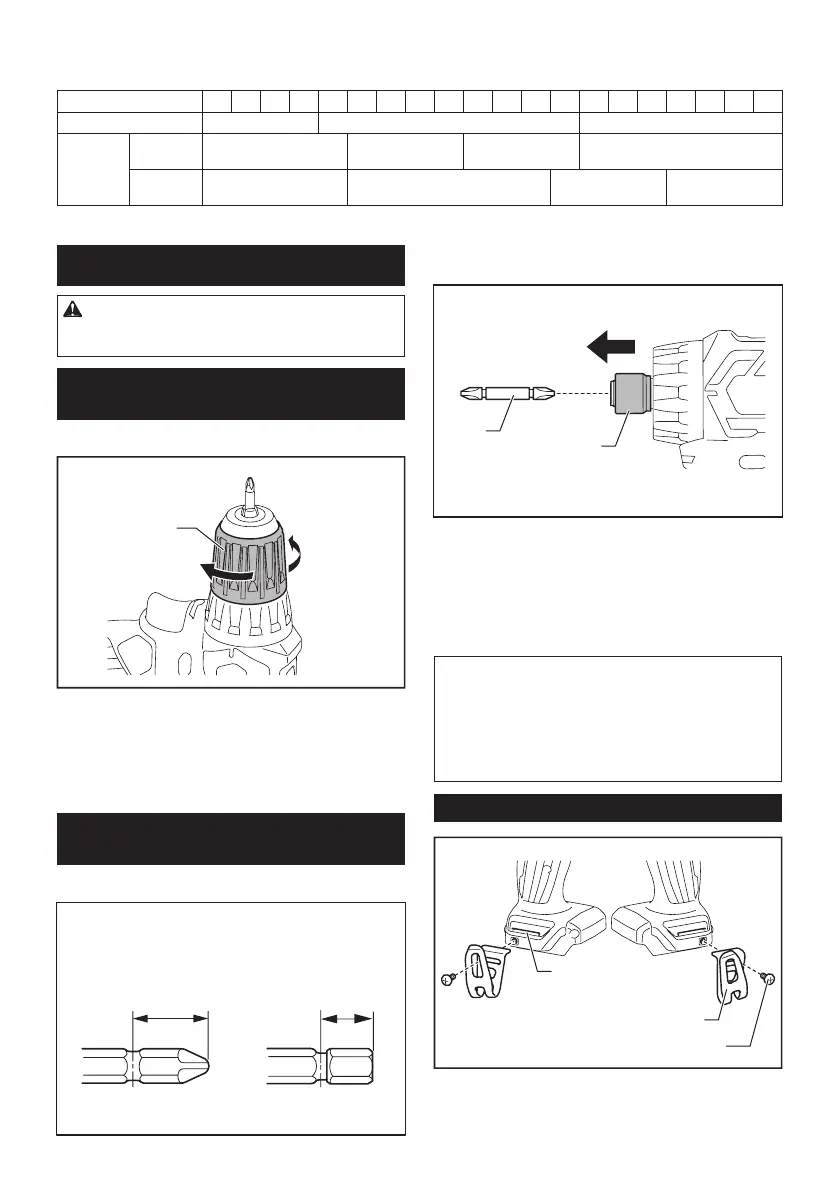

For Model FD07 (optional accessory)

3

2

1

►1. Sleeve 2. Close 3. Open

Turnthesleevecounterclockwisetoopenthechuck

jaws.Placethedriverbit/drillbitinthechuckasfar

asitwillgo.Turnthesleeveclockwisetotightenthe

chuck.Toremovethedriverbit/drillbit,turnthesleeve

counterclockwise.

Installing or removing driver bit/

socket bit

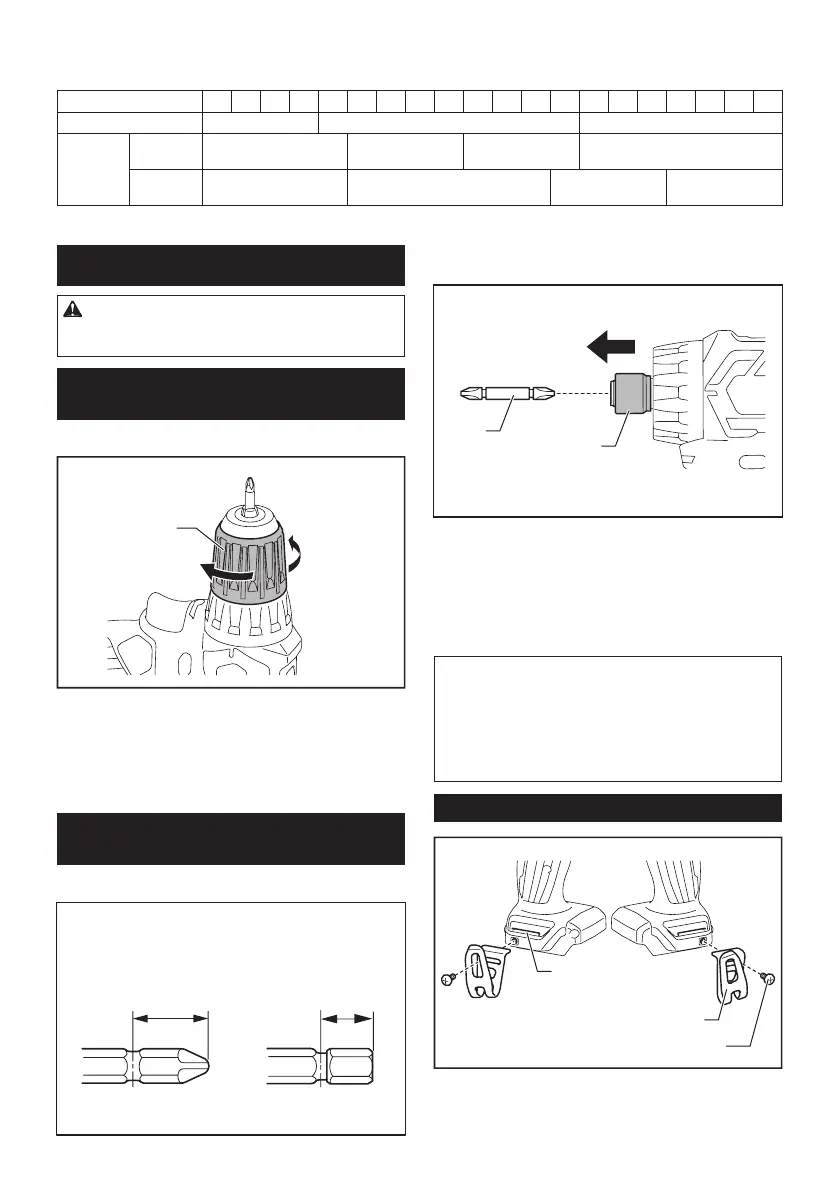

For Model FD08 (optional accessory)

12 mm

(15/32”)

9 mm

(3/8”)

Useonlythedriverbit/socketbitshowninthegure.Do

not use any other driver bit/socket bit.

2

1

►1. Driver bit 2. Sleeve

Toinstallthedriverbit,pullthesleeveinthedirectionof

the arrow and insert the driver bit into the sleeve as far

as it will go.

Thenreleasethesleevetosecurethedriverbit.

Toremovethedriverbit,pullthesleeveinthedirection

of the arrow and pull the driver bit out.

NOTE: If the driver bit is not inserted deep enough

into the sleeve, the sleeve will not return to its original

position and the driver bit will not be secured. In this

case, try re-inserting the bit according to the instruc-

tions above.

NOTE:Afterinsertingthedriverbit,makesurethatit

isrmlysecured.Ifitcomesout,donotuseit.

Installing hook

1

2

3

►1. Groove 2. Hook 3. Screw

Loading...

Loading...