P 3 / 20

Repair

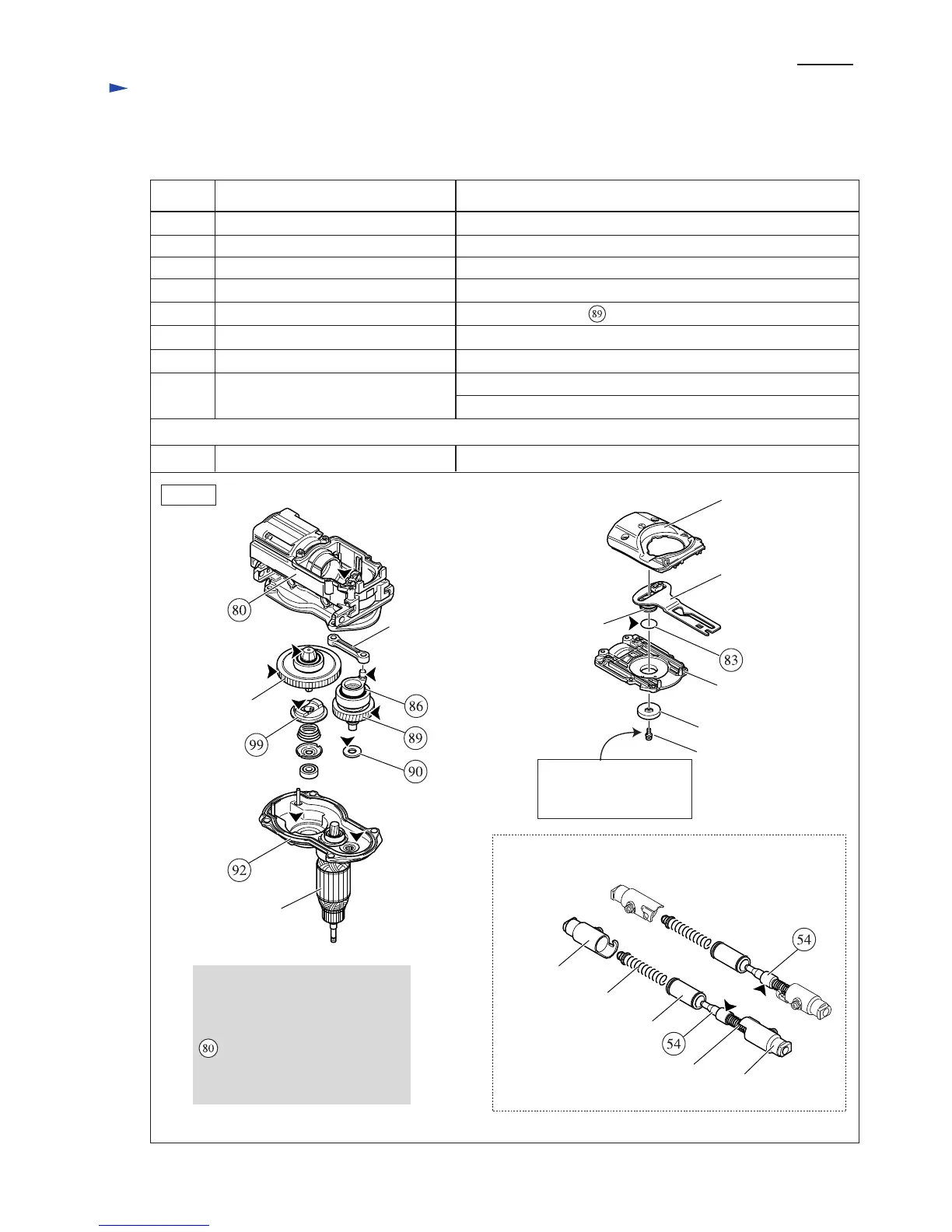

[2] LUBRICATION

Apply Makita grease R. No.00 to the portions designated with black triangle to protect parts and product

from unusual abrasion.

80 Crank housing complete

83 O ring 18

About 20g into the Crank room

92 Gear housing complete About 22g into the Gear room

86 Crank shaft

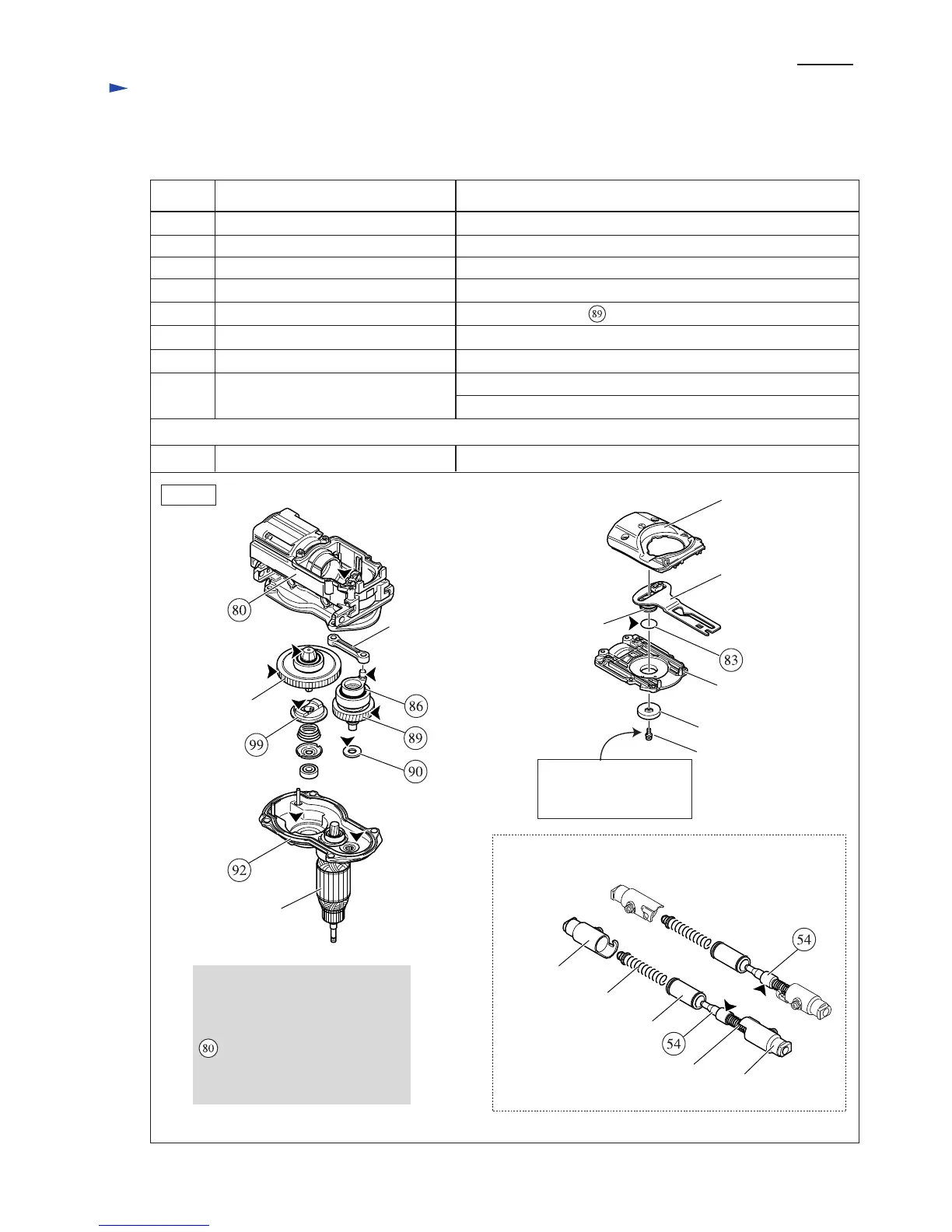

54 Counter weight (2 pcs)

Active dynamic vibration absorber of HR4010C and HR4011C

Crank pin portion

90 Flat washer 10

Whole portion

89 Helical gear 38 Teeth portion

Surface that contacts Helical gear 38

Surface that contacts Torque limiter assembly99 Driving flange

Item No. Description Portion to lubricate

Teeth portion of Helical gear 61

Teeth portion of Straight bevel gear 7

--- Torque limiter assembly

Fig. 1B

Link lever

Pan head screw M4x10

Crank cap

Crank cap cover

Control plate

Crank lever

Connecting rod

Apply adhesive to the

threaded portion when

tightening this screw.

Armature

Pipe 16

Pipe holder

Pipe holder

Compression

spring 11

Compression

spring 11

Active dynamic vibration absorber

of HR4010C and HR4011C

Surface that contacts Pipe 16

Note:

For long tool life, at the same time

when Carbon brushes are replaced,

it is recommended to lubricate

Crank housing complete with

Makita grease R.No.00.

(See "[4] Maintenance Program".)

Torque limiter

assembly

Loading...

Loading...