ultrasonics by placing the slurry and its beaker into an ultrasonic bath. It will be

apparent if this has been effective. Further ultrasonics can be applied when the

sample is added to the tank, if necessary. This will often prevent

re-agglomeration, but is not always necessary.

%

Caution

Samples with unstable concentrations

When adding the sample to the tank using the measure-inspect facility of the

software you will occasionally experience obscurations that change during the

dispersion period. Most samples will disperse very quickly so you will not notice

the obscuration value rising. With some samples however the slow dispersion of

the sample can be clearly seen. A measurement should not be made until the

obscuration has stabilised - indicating that the sample has properly dispersed.

The obscuration and its behaviour during the dispersion of the sample can also

warn of other potential problems.

If the obscuration decreases then the size of the particles within the sample may

be increasing, either the sample is sticking together or the particles are actually

swelling due to the dispersant. Other causes could be the larger particles settling

out due to inadequate pumping and stirring or even the particles dissolving.

If the obscuration increases rapidly it could be that particles are attaching

themselves to the cell windows due to surface charges. The material is therefore

in the analyser beam continuously and the obscuration appears to increase. To

solve this problem use an appropriate admixture.

Bubbles

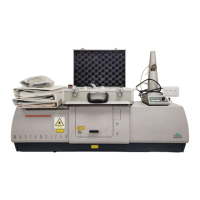

Bubbles have been mentioned earlier in this chapter. To the Mastersizer optics all

bubbles are seen as particles and are therefore measured. You should always be

wary of bubbles within the system.

Be wary of using ultrasonics with fragile particles as the ultrasonic action may

actually break up the particles themselves. If in any doubt, microscopic

observation before and after ultrasonics should establish whether it has been

beneficial or not.

CHAPTER 9

GETTING STARTED

Page 9.7

Loading...

Loading...