Maintenance and care

24

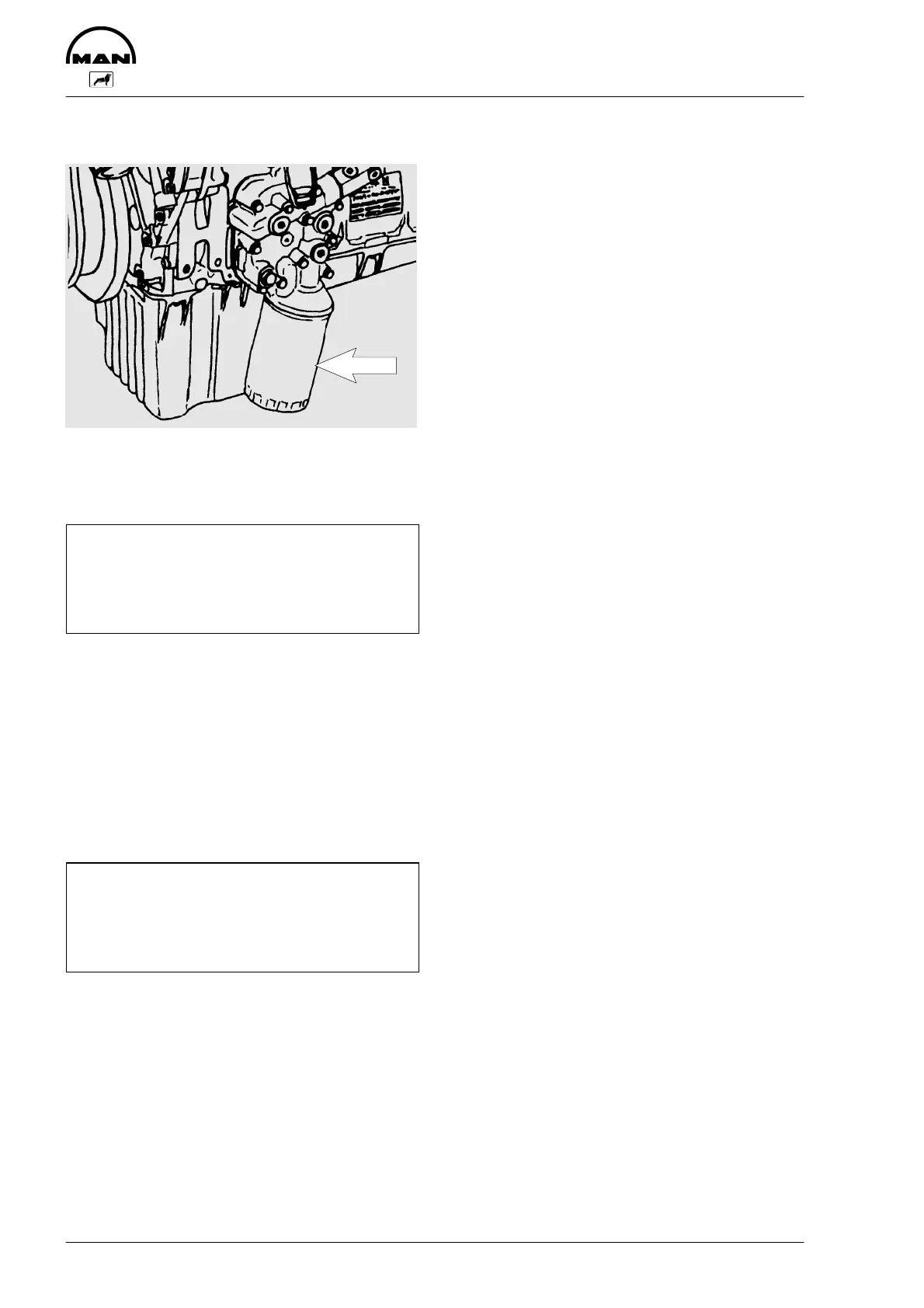

Screw-on type oil filter

A tape wrench is a suitable tool for un-

screwing the disposable filter box.

Caution:

The filter box is full of hot oil. Hold a

suitable vessel under the filter box to

catch the oil which flows out.

Apply light coating of oil on gasket.

Screw on filterbox and tighten by hand.

Fill engine with oil. Run engine for a short

period and check filter for possible leaks.

Retighten if necessary.

Every time oil change is made, the filter

cartridge should be renewed.

Caution:

Used oil filters are classed as danger-

ous waste and must be disposed of

accordingly.

Fuel system

Fuel

If Diesel fuel which contains moisture is

used the injection system and the cylinder

liners / pistons will be damaged. This can

be prevented to same extent by filling the

tank as soon as the engine is switched off

while the fuel tank is still warm (formation

of condensation is prevented). Drain

moisture from storage tanks regularly. In-

stallation of a water trap upstream of the

fuel filter is also advisable. Do not use any

additives to improve flow properties in

winter.

Injection pump

No alterations must be made to the injec-

tion pump. If the lead seal is damaged the

warranty on the engine will become null

and avoid.

Faults

We urgently recommend that you have

faults in the injection pump rectified only in

an authorised specialist workshop.

Bleeding the fuel system

Bleeding the fuel filters is by releasing the

bleed screws and operating the manual

primer (fit new seals).

The suction chamber of the injection

pump is continuously bled via the relief

valve during operation. If the suction

chamber is completely empty, e.g., when

fitting a new pump, filling and bleeding it is

by actuating the manual primer.

Loading...

Loading...