Maintenance and care

25

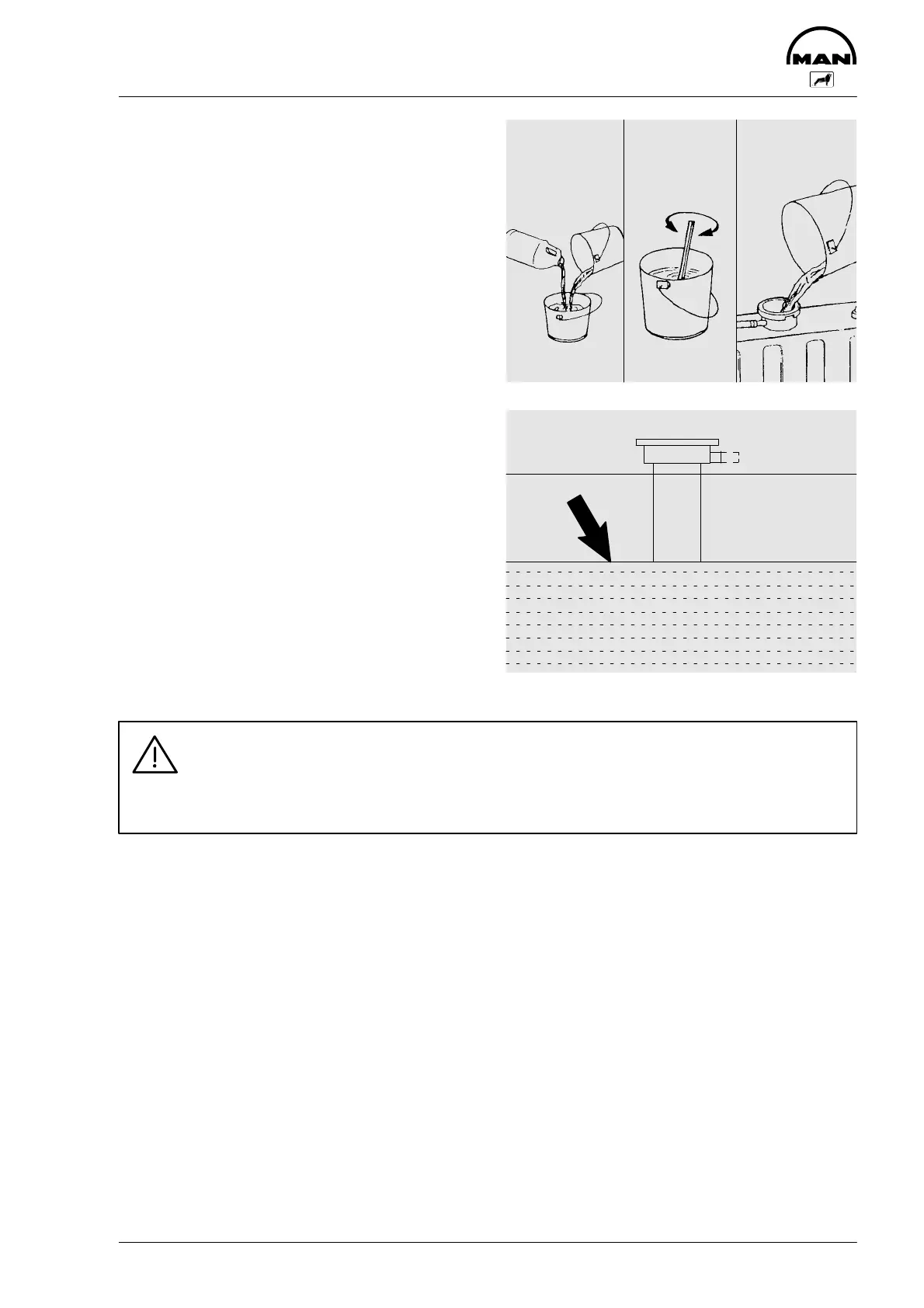

Adding coolant / Bleeding cooling sys-

tem

(when engine has cooled down)

The engine cooling system should be

filled with a mixture of potable tap water

and antifreeze based on ethylene glycol

and anti-corrosion agent (see “Fuel, Lu-

bricants and Coolants for MAN Industrial

Gas Engines”).

Coolant must be added in accordance

with the filling instructions issued by the

manufacturer of the block-type thermal

power plant. Do not add cold coolant to a

warm engine. Ensure that the water / anti-

freeze ratio is the same as before addition

of the coolant.

D Unscrew cover

D Add coolant slowly

D Screw the cover back on

D Run the engine for a short time and

then check the coolant level again.

Danger:

If in exceptional circumstances, it is necessary to check the coolant level when

the engine is warm or to open the cooling circuit, the safety instructions of the

manufacturer of the power plant must be followed.

Incorrect addition of antifreeze and anti-corrosion agent may lead to deposits of lime and

rust in the engine coolant circuit, which impairs the cooling effect.

In such cases the coolant circuit must be cleaned at suitable intervals.

Loading...

Loading...