Checking and setting

29

Adjusting ignition timing

Checking ignition timing

Ignition timing should be checked every

2,000 hours of operation.

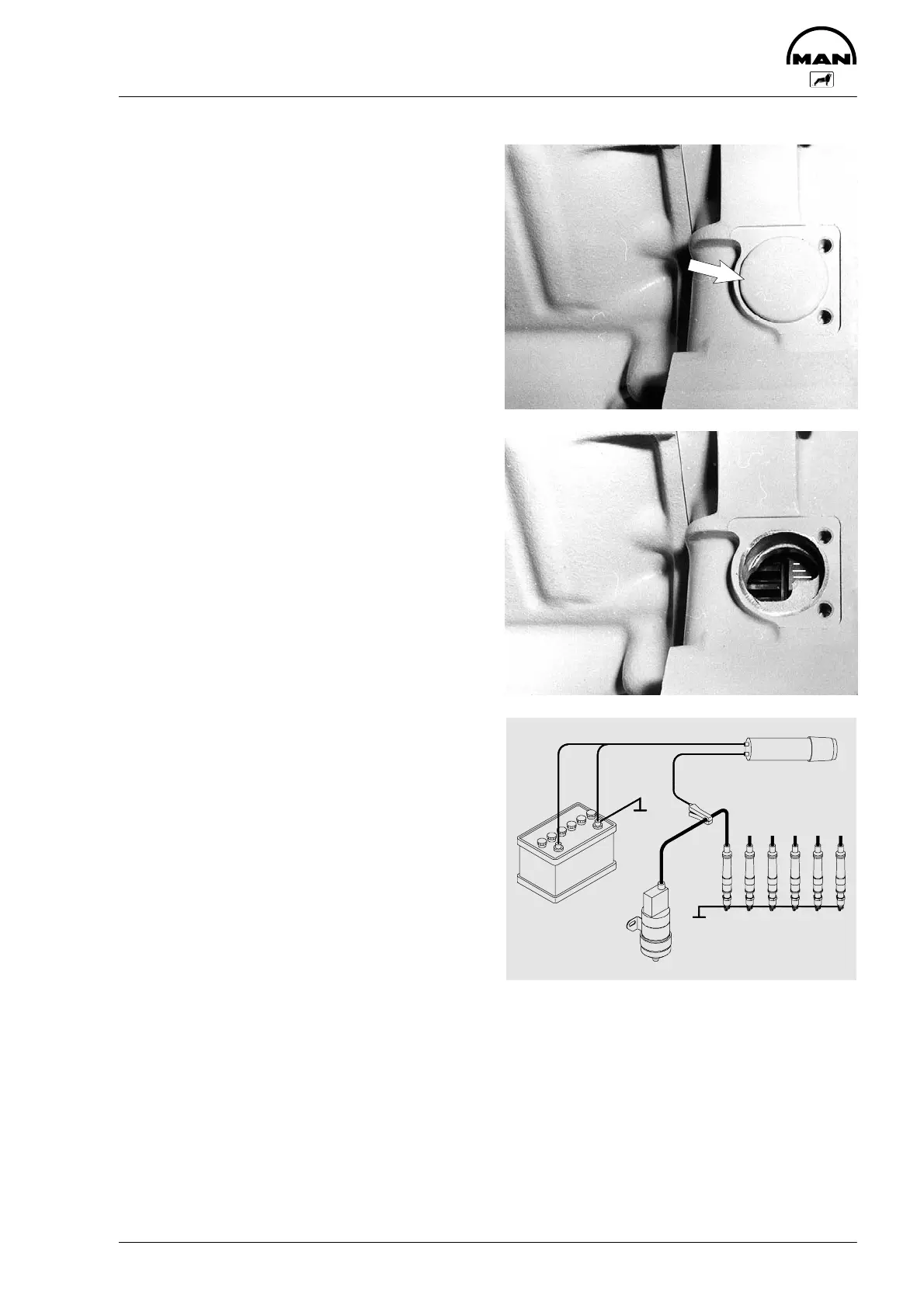

Open cover on flywheel housing (arrow).

Before the first cylinder reaches TDC, you

will see angle markings on the flywheel.

These range from 40° before TDC to 0°.

There is a reference edge on the flywheel

housing to act as a corresponding marker.

The ignition point depends on the air ratio

λ at which the engine is being operated.

The setting is correct when ignition in cyl-

inder 1 takes place at 16° before TDC for

λ = 1 or 8° before TDC for λ = 1.5.

Check and set the ignition point with a

stroboscopic lamp. This must be done

with the engine running.

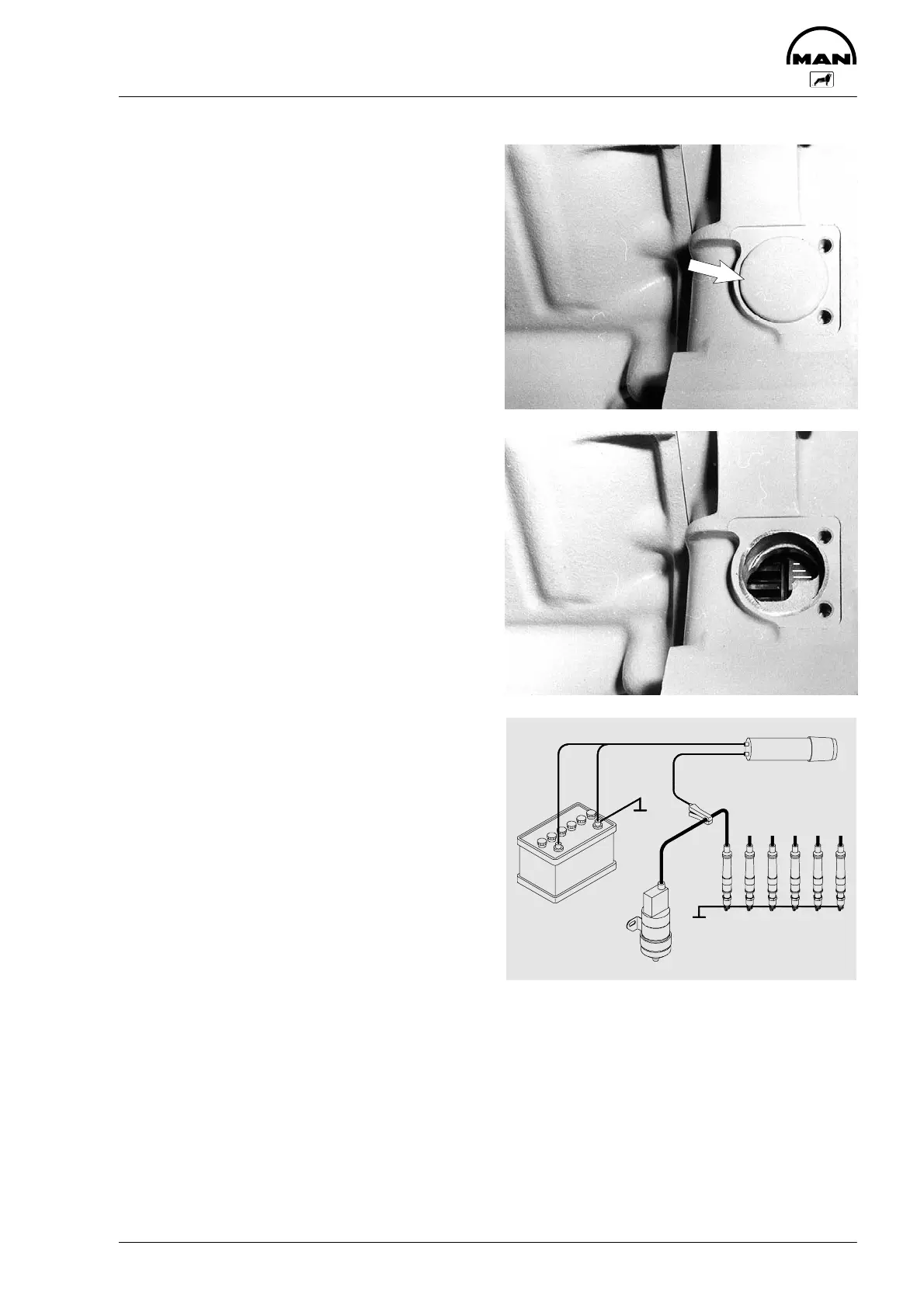

Connect up the stroboscopic lamp as fol-

lows.

D Connect connecting cable to the bat-

tery terminals: red clamp to positive ter-

minal, black clamp to negative terminal.

D Attach the inductive clamp transducer

to the ignition cable of cylinder 1 (end

remote from flywheel).

The clamp transducer senses the ignition

pulse and transmits it to the stroboscopic

lamp. The lamp flashes simultaneously

with the ignition spark of cylinder 1.

If the stroboscopic lamp is pointed at the

inspection hole, the selected ignition

marking appears to be stationary.

Loading...

Loading...