Âo

1000H - ROUTINE MAINTENANCE - EVERY 1000 HOURS OF SERVICE OR 2 YEARS

ALSO PERFORM THE 500 HOUR PERIODIC MAINTENANCE OPERATIONS.

CHECK Safety belt

IMPORTANT

If the seat belt is defective (fixing, locking, cuts, tears, etc.), the lift truck must not be used.

Repair or replace the seat belt immediately.

SEAT BELT WITH TWO ANCHORING POINTS

- Check the following points:

• Fixing of the anchoring points on the seat.

• Cleanness of the strap and the locking mechanism.

• Triggering of the locking mechanism.

• Condition of the strap (cuts, curled edges).

REELED SEAT BELT WITH TWO ANCHORING POINTS

- Check the points listed above together with the following points:

• The correct winding of the belt.

• Condition of the reel guards.

• The roller locking mechanism by giving the strap a sharp tug.

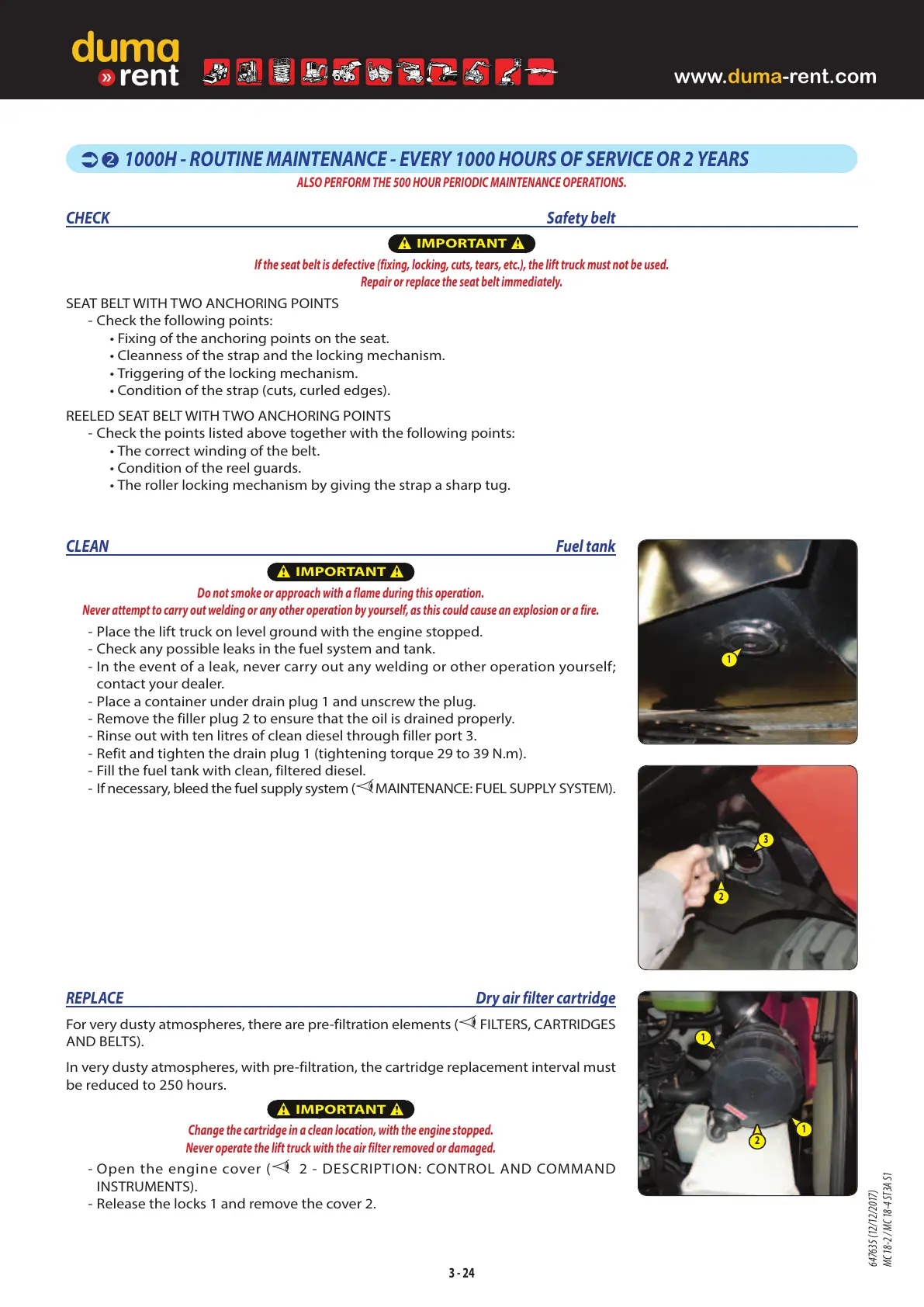

CLEAN Fuel tank

IMPORTANT

Do not smoke or approach with a flame during this operation.

Never attempt to carry out welding or any other operation by yourself, as this could cause an explosion or a fire.

- Place the lift truck on level ground with the engine stopped.

- Check any possible leaks in the fuel system and tank.

- In the event of a leak, never carry out any welding or other operation yourself;

contact your dealer.

- Place a container under drain plug 1 and unscrew the plug.

- Remove the filler plug 2 to ensure that the oil is drained properly.

- Rinse out with ten litres of clean diesel through filler port 3.

- Refit and tighten the drain plug 1 (tightening torque 29 to 39 N.m).

- Fill the fuel tank with clean, filtered diesel.

- If necessary, bleed the fuel supply system (

MAINTENANCE: FUEL SUPPLY SYSTEM).

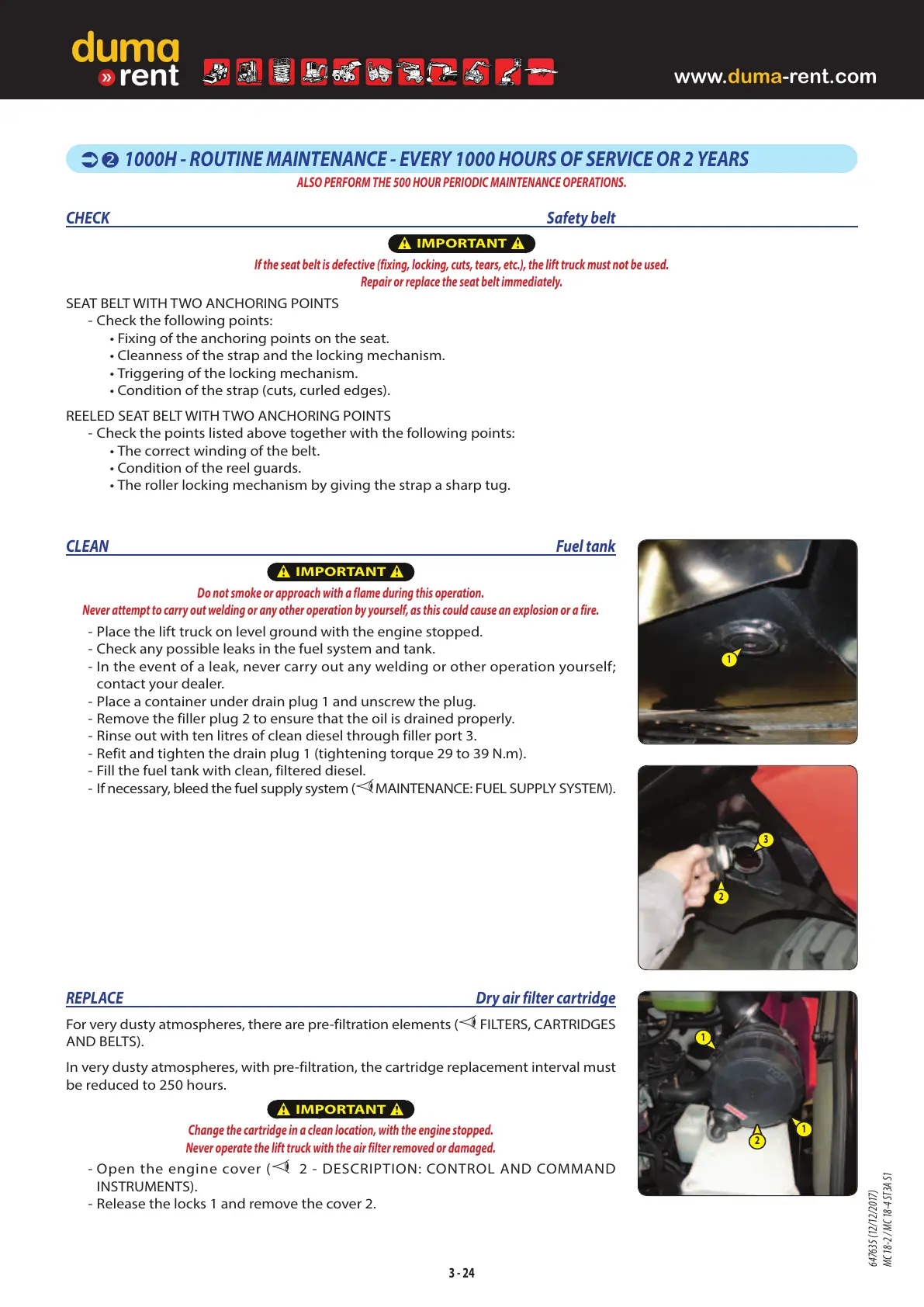

REPLACE Dry air filter cartridge

For very dusty atmospheres, there are pre-filtration elements ( FILTERS, CARTRIDGES

AND BELTS).

In very dusty atmospheres, with pre-filtration, the cartridge replacement interval must

be reduced to 250 hours.

IMPORTANT

Change the cartridge in a clean location, with the engine stopped.

Never operate the lift truck with the air filter removed or damaged.

- Open the engine cover ( 2 - DESCRIPTION: CONTROL AND COMMAND

INSTRUMENTS).

- Release the locks 1 and remove the cover 2.

3 - 24

1

1

2

1

2

3

647635 (12/12/2017)

Loading...

Loading...