A - DAILY OR EVERY 10 HOURS OF SERVICE

A1 – ENGINE OIL LEVEL

CHECK

Place the lift truck on level ground with the engine stopped, and let the oil settle in

the sump.

- Lift up the overhead guard or the cab (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS).

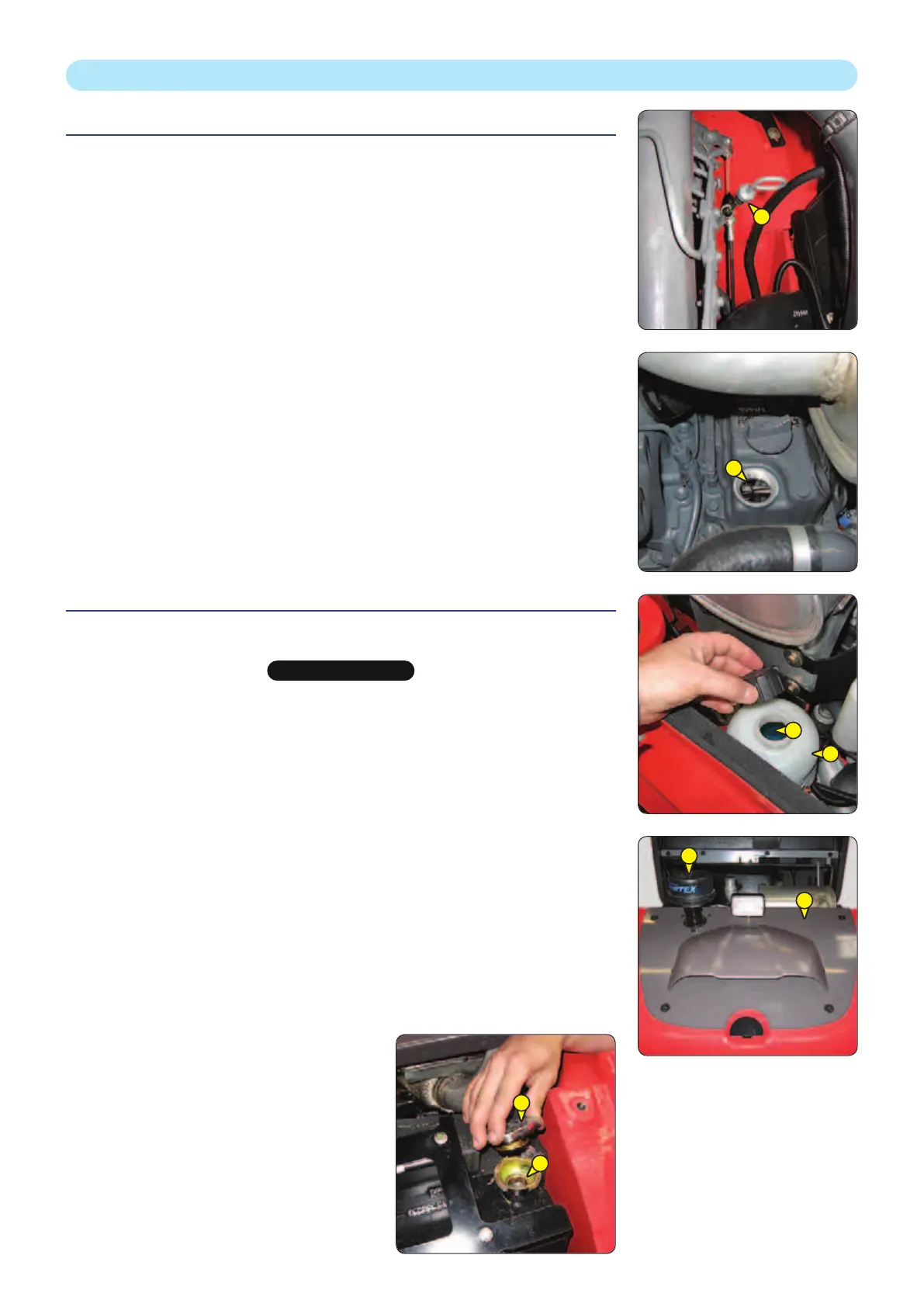

- Pull out dipstick 1.

- Clean the dipstick and check the correct level between the two notches.

- If necessary, add oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL) through the

filler port 2.

- Visually check that there is no leakage or seepage of oil in the engine.

A2 – COOLING LIQUID LEVEL

CHECK

Place the lift truck on level ground with the engine stopped, and allow the engine to cool.

IMPORTANT

To avoid any risk of spraying or burning, wait until the engine has cooled down before removing the cooling circuit

filler plug.

If the cooling liquid is very hot, add only hot cooling liquid (80 °C).

In an emergency, you can use water as a cooling liquid, then change the cooling circuit liquid as soon as possible (see: 3 -

MAINTENANCE: F1 - COOLING LIQUID).

- Lift up the overhead guard or the cab (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS).

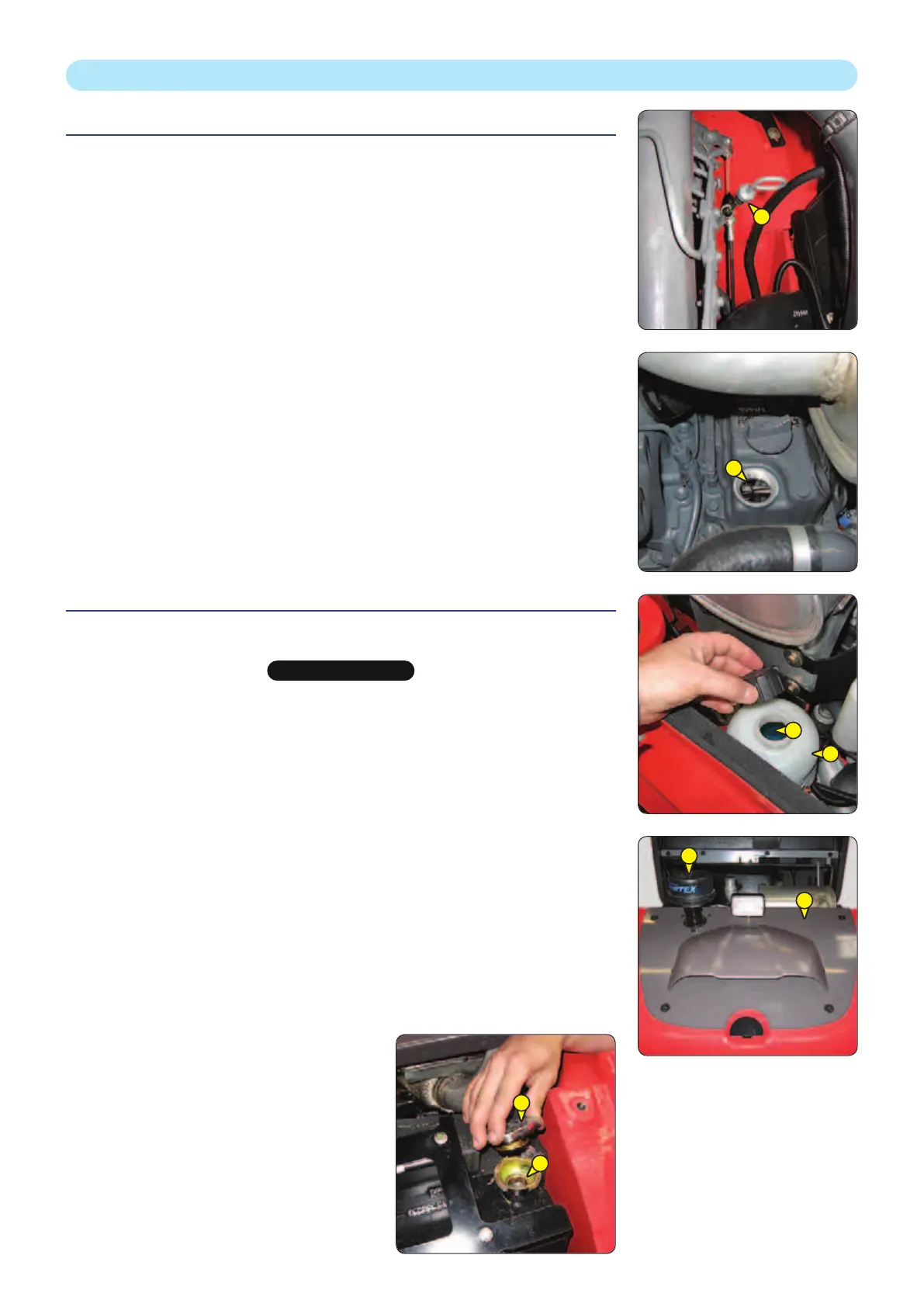

- The liquid must be at the MAXIMUM level on the expansion tank 1.

- If necessary, add cooling liquid (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL)

through the filler port 2.

- Visually check that there is no leakage in the radiator and pipes.

When the expansion tank is empty, check the level in the radiator before filling the

expansion tank.

- Refit cover plate 4 and pre-filter 3.

- Slowly turn the cap of the radiator 5 up to the safety stop.

- Allow the pressure and the steam to escape.

- Press down and turn the cap so as to release it.

- Add cooling fluid through the filler port 6 (see:

3 - MAINTENANCE: LUBRICANTS AND FUEL).

- Lubricate slightly the filler neck in order to

facilitate the setting and the removal of the

radiator cap.

3 - 10

1

2

2

1

3

4

5

6

647468 (26/11/2018)

SI 25/30/35 ... 4ST3A ; MH 25-4 ... 4ST3A

Loading...

Loading...