E - EVERY 1000 HOURS OF SERVICE OR TWO YEARS

Carry out the operations described previously as well as the following operations.

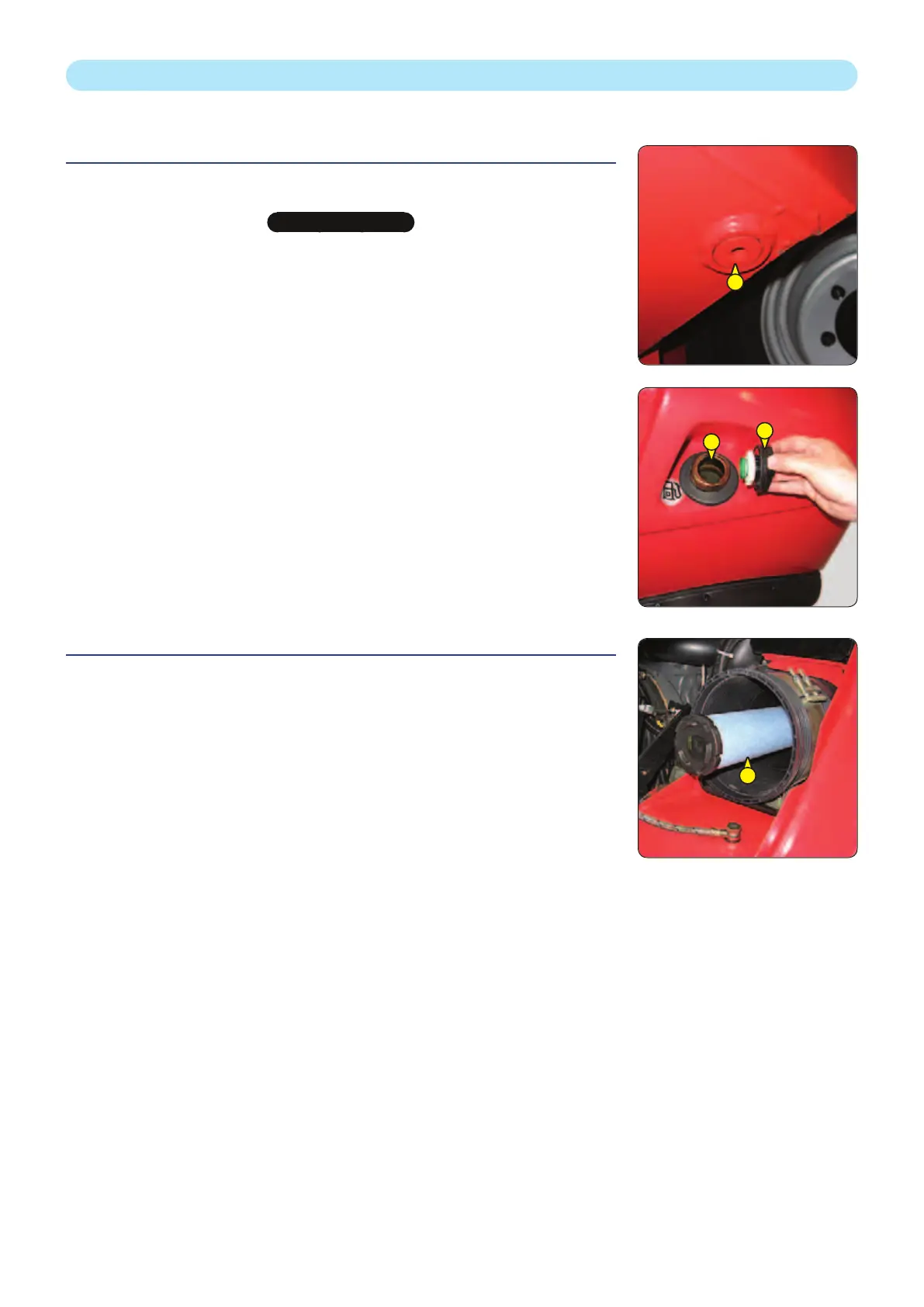

E1 – FUEL TANK

CLEAN

Place the lift truck on level ground with the engine stopped.

IMPORTANT

Do not smoke or approach with a flame during this operation.

Never attempt to carry out welding or any other operation by yourself, as this could cause an explosion or a fire.

- Inspect the parts of the fuel circuit and the tank liable to leak, both visually and

by touch.

- In the event of a leak, contact your dealer.

- Place a container under drain plug 1 and unscrew the plug.

- Remove the filler plug 2 to ensure that the oil is drained properly.

- Rinse out with ten litres of clean diesel through filler port 3.

- Refit and tighten the drain plug 1 (tightening torque 29 to 39 N.m).

- Fill the fuel tank with clean diesel filtered through the filler port.

- Refit the filler plug 2.

- If necessary, bleed the fuel supply system (see: 3 - MAINTENANCE: G1 - FUEL SUPPLY

SYSTEM).

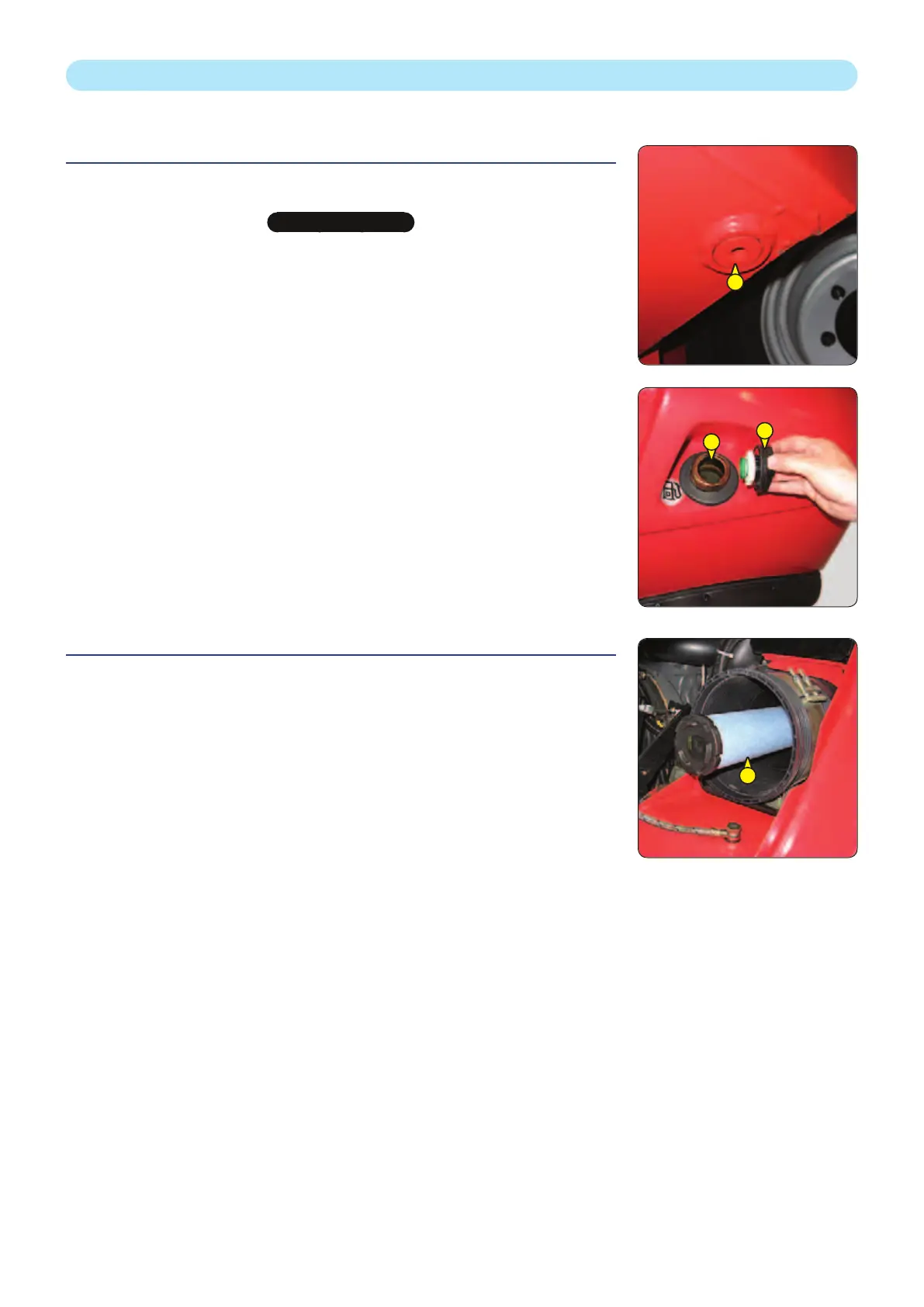

E2 – SAFETY DRY AIR FILTER CARTRIDGE

REPLACE

- For the disassembly and reassembly of the cartridge, see: 3 - MAINTENANCE: D1 -

DRY AIR FILTER CARTRIDGE.

- Remove the dry air filter safety cartridge 1 carefully, to minimise dust fall.

- Clean the gasket surface on the filter with a damp, clean lint-free cloth.

- Check the condition of the new safety cartridge before fitting (see: 3 - MAINTENANCE:

FILTERS AND BELTS).

- Introduce the cartridge into the filter axis and push it in, pressing the edges and

not the middle.

NOTE: The safety cartridge replacement frequency is given for information only.

The safety cartridge must be changed for every two changes of the air filter

cartridge.

3 - 22

1

3

2

1

647468 (26/11/2018)

SI 25/30/35 ... 4ST3A ; MH 25-4 ... 4ST3A

Loading...

Loading...