E3 – HYDRAULIC OIL

DRAIN

E4 – SUCTION STRAINER FOR HYDRAULIC OIL TANK

CLEAN

E5 – HYDRAULIC OIL TANK FILTER CAP

REPLACE

Place the lift truck on level ground with the engine stopped, the mast tilted backward

and lowered as far as possible.

IMPORTANT

Dispose of the drain oil in an ecological manner.

Before any intervention, thoroughly clean the area surrounding the drain plug and the suction cover on the hydraulic

tank.

- Lift up the overhead guard or the cab (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS).

DRAINING THE OIL

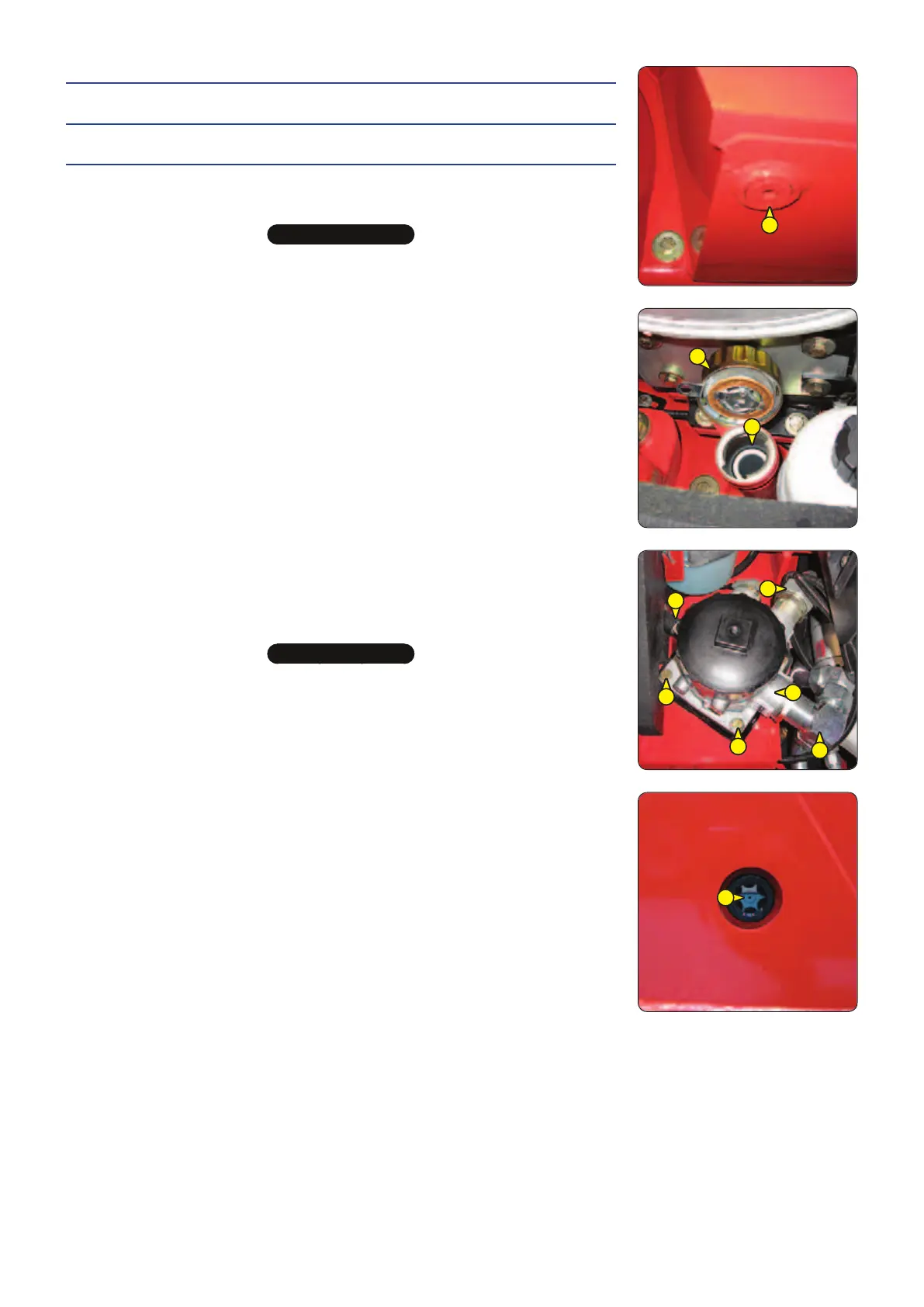

- Place a container under drain plug 1 and unscrew the plug.

- Remove level and filling plug 2 to ensure that the oil is drained properly and discard.

CLEANING THE STRAINER

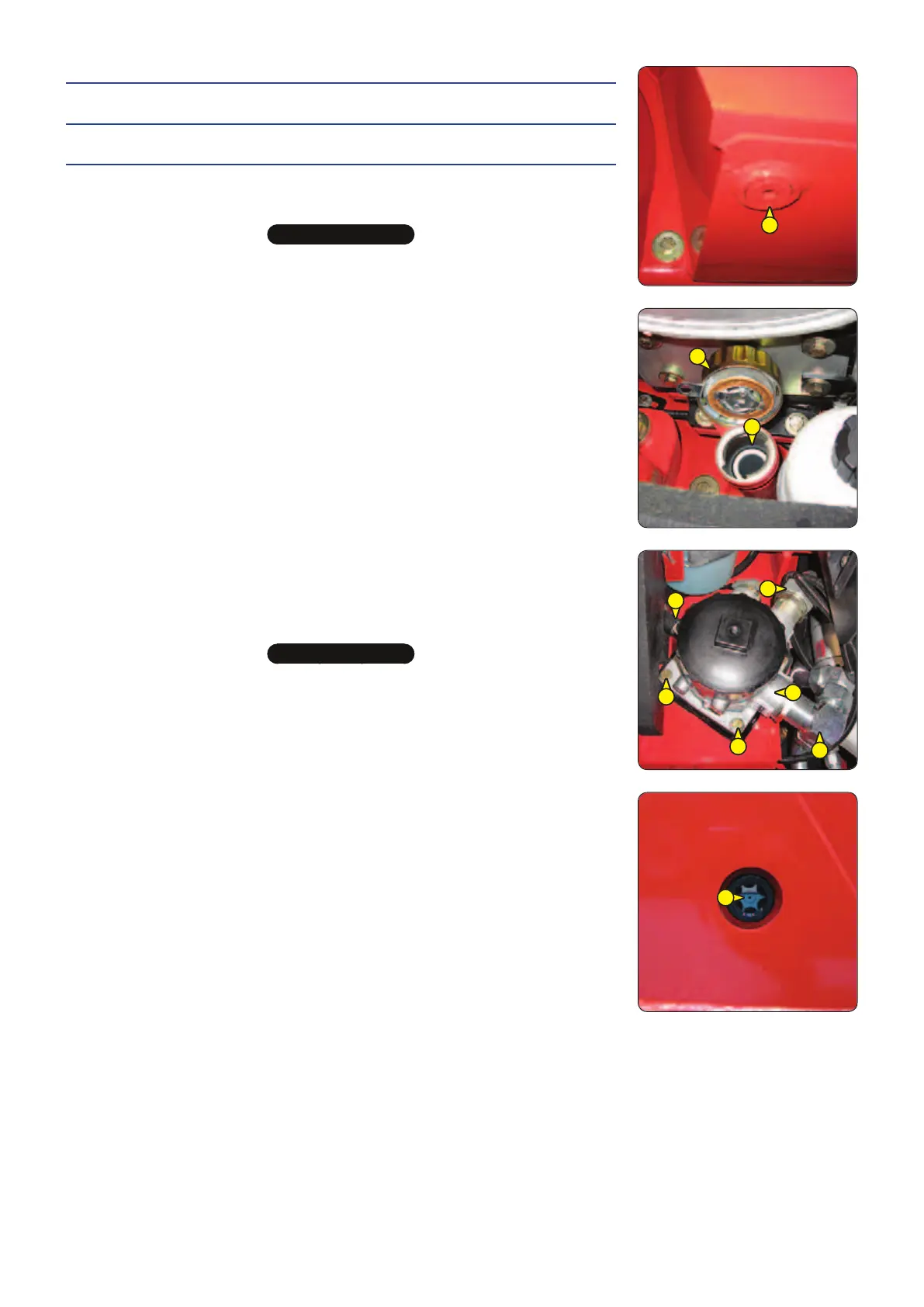

- Disconnect clogging indicator 3.

- Disconnect the hoses 4 at the level of hydraulic return oil filter 5.

- Unscrew the four 6 screws and remove filter assembly 5.

- Unscrew the suction strainer at the bottom of the tank, clean it with the help

of a compressed air jet, check its condition and change it, if necessary (see: 3 -

MAINTENANCE: FILTERS CARTRIDGES AND BELTS).

- Reassemble the strainer, the filter and re-connect the hoses and the clogging indicator.

FILLING WITH OIL

- Clean and refit the drain plug 1 (tightening torque 72 to 88 N.m).

- Fill up with oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL) through filler port 7.

IMPORTANT

Use a clean container and funnel and clean the underside of the oil drum before filling.

- Observe the oil level on dipstick 8, the oil level should be at the level of the red point.

- Check for any possible leaks at the drain plug.

- Replace filler plug with a new filler plug 2 (see: 3 - MAINTENANCE: FILTERS CARTRIDGES

AND BELTS).

HYDRAULIC CIRCUIT DECONTAMINATION

- Let the engine run (accelerator pedal at halfway travel) for 5 minutes without using

anything on the lift truck, then for 5 more minutes while using completely the

hydraulic movements (except the steering system).

- Accelerate the engine at full speed for 1 minute, then activate the steering system.

- This operation makes a pollution abatement of the circuit possible through the

hydraulic return oil filter.

3 - 23

1

7

2

3

6

4

5

6

4

8

647468 (26/11/2018)

SI 25/30/35 ... 4ST3A ; MH 25-4 ... 4ST3A

Loading...

Loading...