National Crane 1-21-2019 Control # 104-07 9-5

1400A SERVICE MANUAL CRANE INSTALLATION

NOTE:

Gross Vehicle Weight Rating (GVWR) is

dependent on all components of the vehicle (axles,

tires, springs, frame, etc.) meeting the

manufacturers’ recommendations. Always specify

GVWR when purchasing trucks.

Diesel engines require a variable speed governor

and energize-to-run fuel solenoid for smooth crane

operation. Electronic fuel injection is also required.

All mounting data is based on a National Series

1400A with subbase and an 85 percent stability

factor.

The complete unit must be installed in accordance

with factory requirements, and a test performed to

determine actual stability and counterweight

requirements per SAE J765; contact the factory for

details.

Transmission neutral safety interlock switch is

required.

PTO REQUIREMENTS

Horsepower

The crane is equipped with a piston hydraulic pump that

supplies 132 LPM (35 GPM) to the hoist,132 LPM (35 GPM)

to the boom and telescope, and 61 LPM (16 GPM) to the

turn and outrigger circuit. The pump shaft needs to turn at

proper RPM as shown below to provide these flows. The

PTO torque rating need to be at least 542 N.m (400 lb-ft) or

63 kW (85 HP) per 1000 RPM of PTO shaft speed.

Direct PTO Mount

Most pump installations can be direct mounted to the PTO

using adapter assemblies available from the PTO supplier. If

the pump is direct mounted, its weight should be supported

by a strap between the pump and the transmission. The

splined shaft coupling in a direct mount pump installation

requires lubrication. A special multi-lube (#200S Silver

Streak) is applied to the shaft during original installation and

should be reapplied to the shaft the on PTO semi-annually

thereafter.

PTO Ratio

Pump shaft speed is determined by truck engine RPM and

PTO ratio:

Pump Shaft Speed = Truck Engine RPM x PTO Ratio

The following PTO ratio and engine speed combinations

provide proper pump shaft speed which is the recommended

maximum speed for the 1400A pump.

The speeds shown below are optimum operating speeds.

The engine must be operated at a speed such that the

horsepower developed is adequate to run the pump under

pressure and provide the required flow. Optimum speed for

the 1400A is 1900 RPM.

Pump Rotation

The hydraulic pump must be installed so that the pump

rotates the same direction as the arrow on the pump

housing. Make certain which direction the power take off

output shaft rotates before selecting a clockwise (CW) or

counter-clockwise (CCW) rotation hydraulic pump. Either

CW or CCW rotation pumps are available and are marked

clearly with a directional arrow on the pump housing.

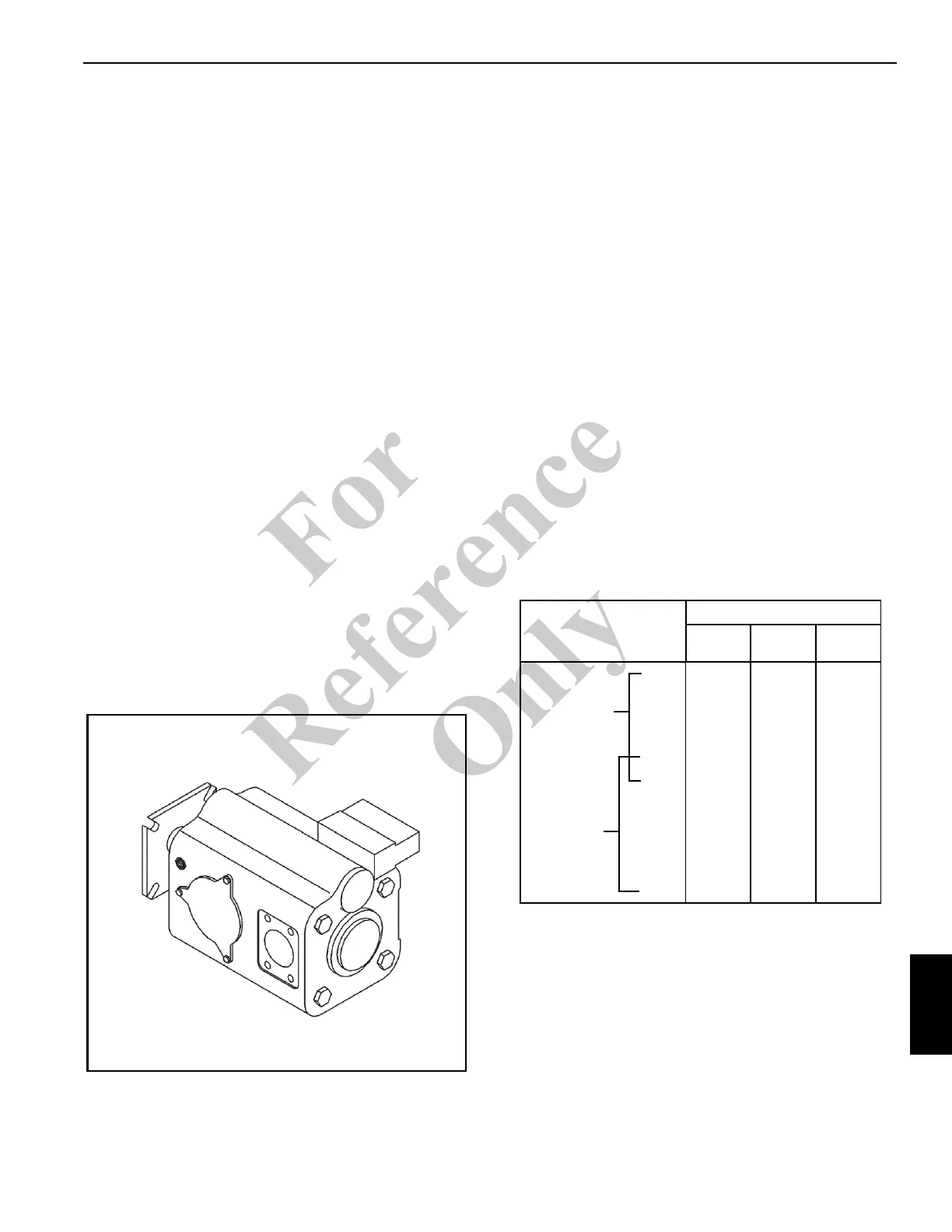

ENGINE SPEED

(RPM)

PTO RATIO

1800 RPM

PUMP

2000 RPM

PUMP

2200 RPM

PUMP

2900 62% 69% 76%

2800 64% 71% 79%

2600 69% 77% 85%

2400 75% 83% 91%

2200 82% 91% 100%

2000 90% 100% 110%

1800 100% 111% 122%

1600 113% 125% 138%

1500 120% 133% 147%

1400 129% 143% 157%

Gasoline

Engine

Optimum

Speed

Range

Diesel

Engine

Optimum

Speed

Range

Fo

r

Reference

Only

Loading...

Loading...