HYDRAULIC SYSTEM SERVICE MANUAL 1400A

2-16 1-21-2019 Control # 104-07

Outrigger Manifolds

The outrigger functions are controlled by two manifolds

located at the front and rear outrigger boxes. The front

manifold contains the extend/retract valve, front outrigger

component valves, and the optional front jack valve. The rear

outrigger manifold contains the rear outrigger component

valves. The valves are operated by solenoids that are

controlled by switches on the outrigger control boxes located

on the side of the truck bed. An optional hand held outrigger

control box can be installed in the crane cab.

Holding Valves

Pilot operated check valves located in the valve block on

each cylinder acts as holding valve to keep the cylinder from

collapse due to hose failure. Do not remove a valve block

unless the cylinder is completely retracted.

Do not try to repair or set the valve pressure. If a holding

valve is suspect, replace it with a new valve.

Swing Gearbox

The standard Glide Swing gearbox is locked in place by an

integrally mounted spring applied disc brake. The swing

brake switch located on the front console and is used to

activate the swing brake and park the turret in position. Press

the switch to activate the swing brake to keep the turret from

rotating. A red LED is illuminated when the swing brake

switch is applied.

The swing control lever can be used to slow and stop the

swing by moving the control lever to the opposite direction of

the swing. For example, if the lever is pushed forward for a

clockwise swing, pull the lever back to slow and stop the

swing.

Crane Function Power Switch

The crane function power switch in the crane cab energizes

a solenoid valve on the crane manifold located in the turret to

activate the controllers in the crane cab. The operator must

be in the operators seat for the crane function power switch

to be active.

HYDRAULIC PUMP

Description

The hydraulic system pressure is supplied by a axial piston

hydraulic pump mounted on the truck power take off (PTO).

The hydraulic piston pump requires a PTO rating of 75 hp

(55.9 kw) per 1000 RPM of shaft speed with 644 N.m (475

lb-ft) of torque.

Removal

If pump replacement is required, the hydraulic fluid should

also be replaced to avoid possible contamination.

1. Drain the hydraulic tank.

2. Tag and disconnect the hydraulic lines from the pump.

3. Remove the bolts from the pump rear mounting bracket.

4. Remove the bolts from the pump mounting flange and

slide the pump out of the PTO drive coupling.

Installation

1. Lubricate the splines on the pump and PTO drive shaft

coupling with heavy lithium grease.

2. Line up the splines on the PTO drive shaft coupling up

with the pump drive shaft and slide the pump drive shaft

into the coupling.

3. Bolt the pump to the PTO with the pump mounting

flange.

4. Bolt the pump rear mounting bracket to the truck

mounting bracket.

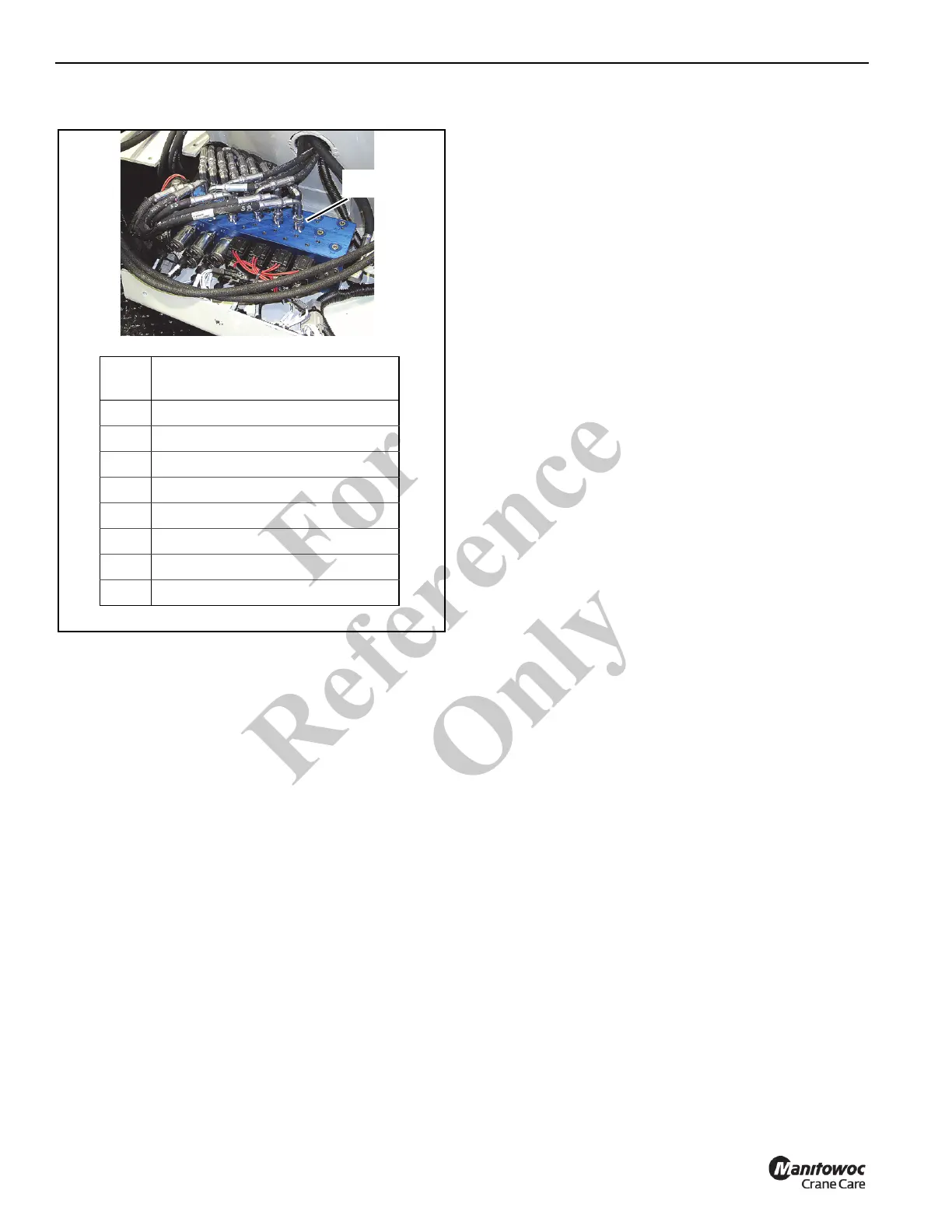

Hydraulic Remote

Control Valve

FIGURE 2-10

8143-8

Valve

Port

Remote Control Function

S1 Turn Right

S2 Boom Up

S3 Hoist down

S4 Telescope In

S5 Turn Left

S6 Boom Down

S7 Hoist Up

S8 Telescope Out

Fo

r

Reference

Only

Loading...

Loading...