A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 29

Troubleshooting — Griddles

WARNING

Inspection, testing and repair of equipment should be performed only by qualified service personnel. Certain

procedures in this section require gas tests or measurements while gas is applied to the unit. Use extreme caution

at all times. If test points are not easily accessible, disconnect main gas line, attach test equipment and reapply gas

supply to continue the test.

Always confirm manifold gas pressure at all times.

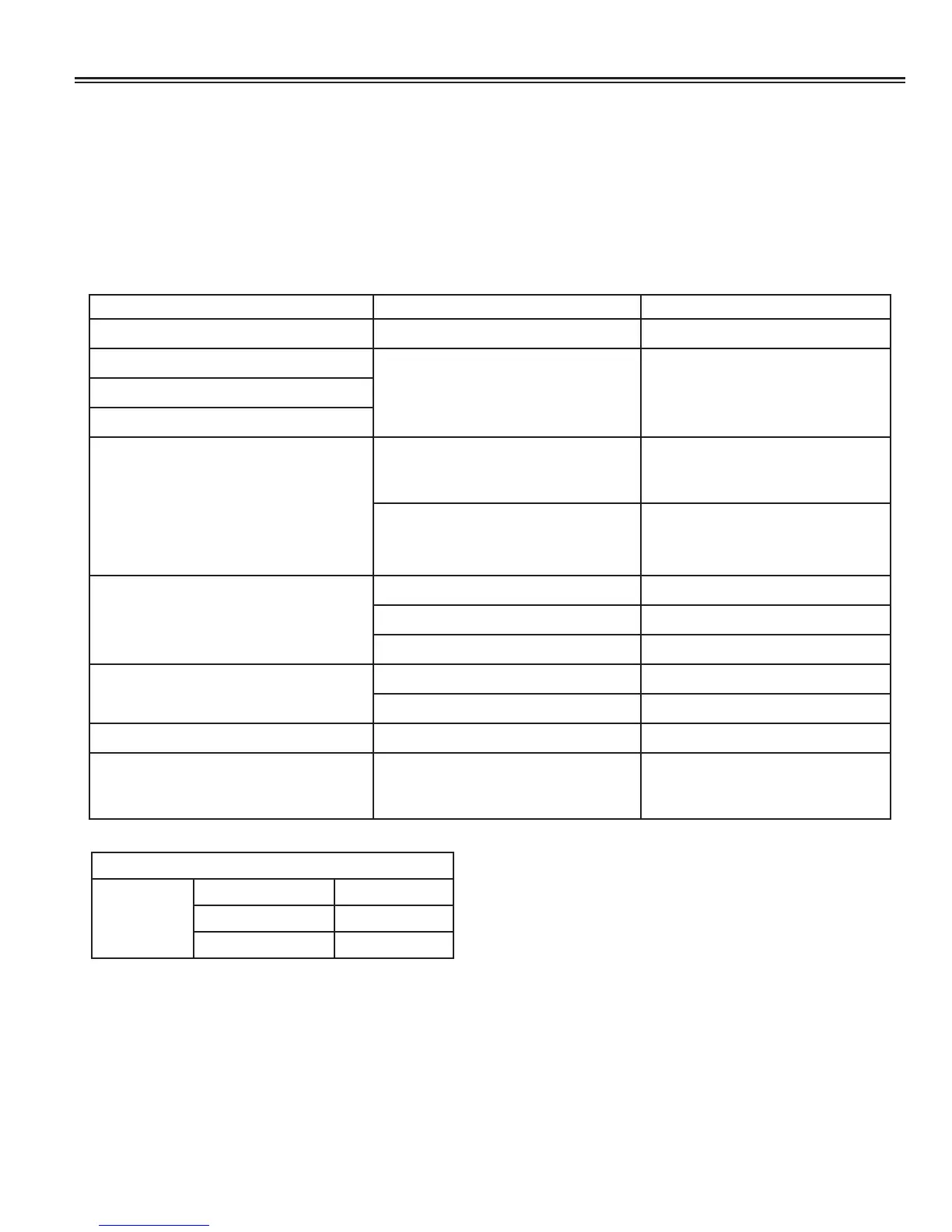

PROBLEM POSSIBLE CAUSE SOLUTION

Burner Flame soft –lazy tip yellow Not enough air mixing with gas Open air shutter

Flames lift off burners

Too much air mixing with gas Reduce air shutter openingFlashes back in burner

“Pop’s” excessively when turned off

Griddle too hot or too cold

Thermostat out of Calibration

(Thermostat Griddle)

Check Calibration temperature

with actual readings. See

calibration procedure.

Hi/lo valve set wrong

(Hi/Lo Valve Griddle)

Adjust hi/lo valve. Adjust on

low setting only, burner cold.

Lowest stable flame

Delayed ignition

Unit over-gassed fired Adjust manifold pressure

Incorrect injector Check injector size

Burner ports plugged Clean burner ports

Pilot burner will not ignite

Pilot flame too small Adjust pilot valve on manifold

Draft in Kitchen Determine cause

Flame lifts off pilot Pilot over-gassed fired Adjust pilot valve

Pilot Outage (SIT Control Models) Bad thermocouple

Check actual mV open and

closed circuits. See table

below.

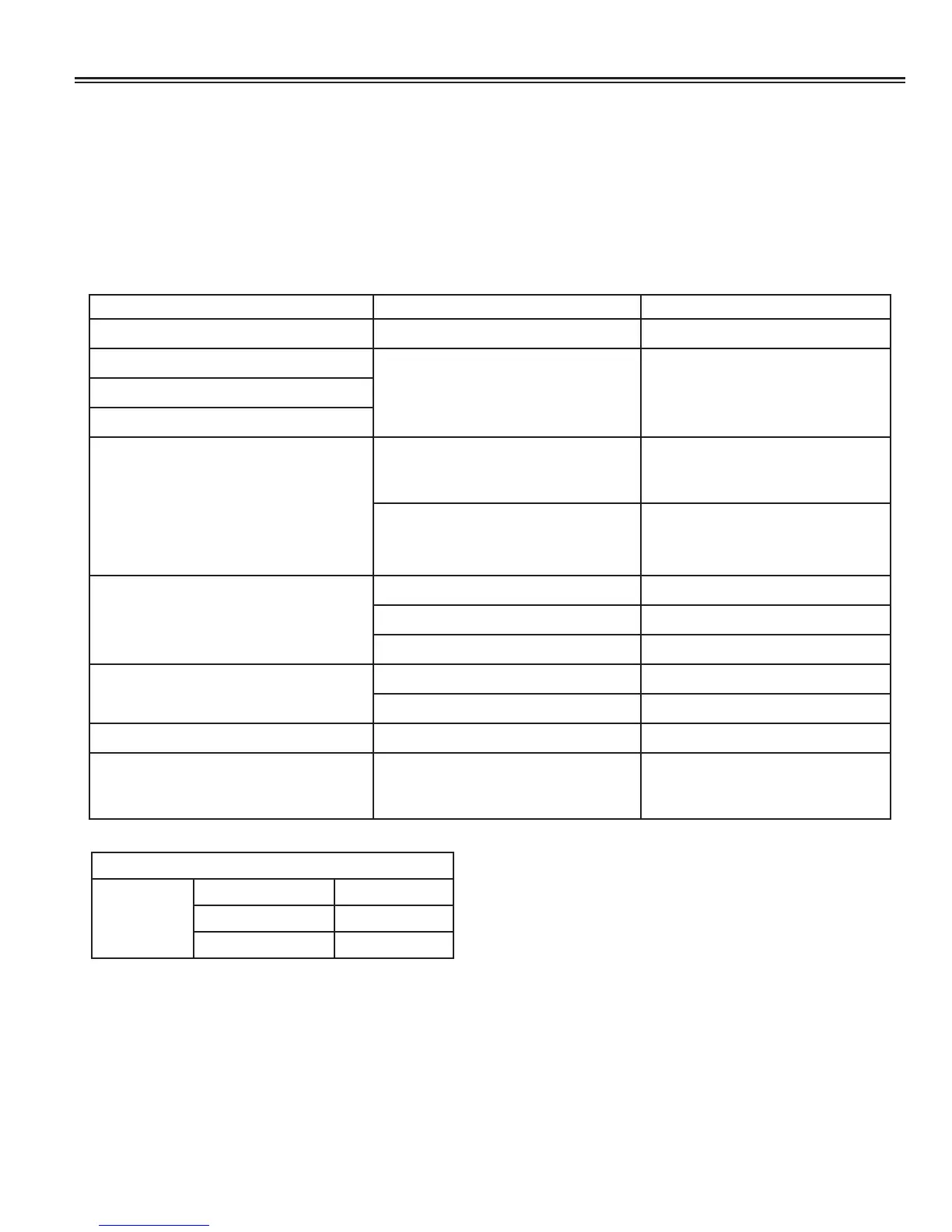

SIT Thermocouple

mV

Closed Circuit 8-14

Open Circuit 18-28

Drop Out 2

Loading...

Loading...