Part Number 000014141 Rev 11 12/23 33

Section 2 Installation

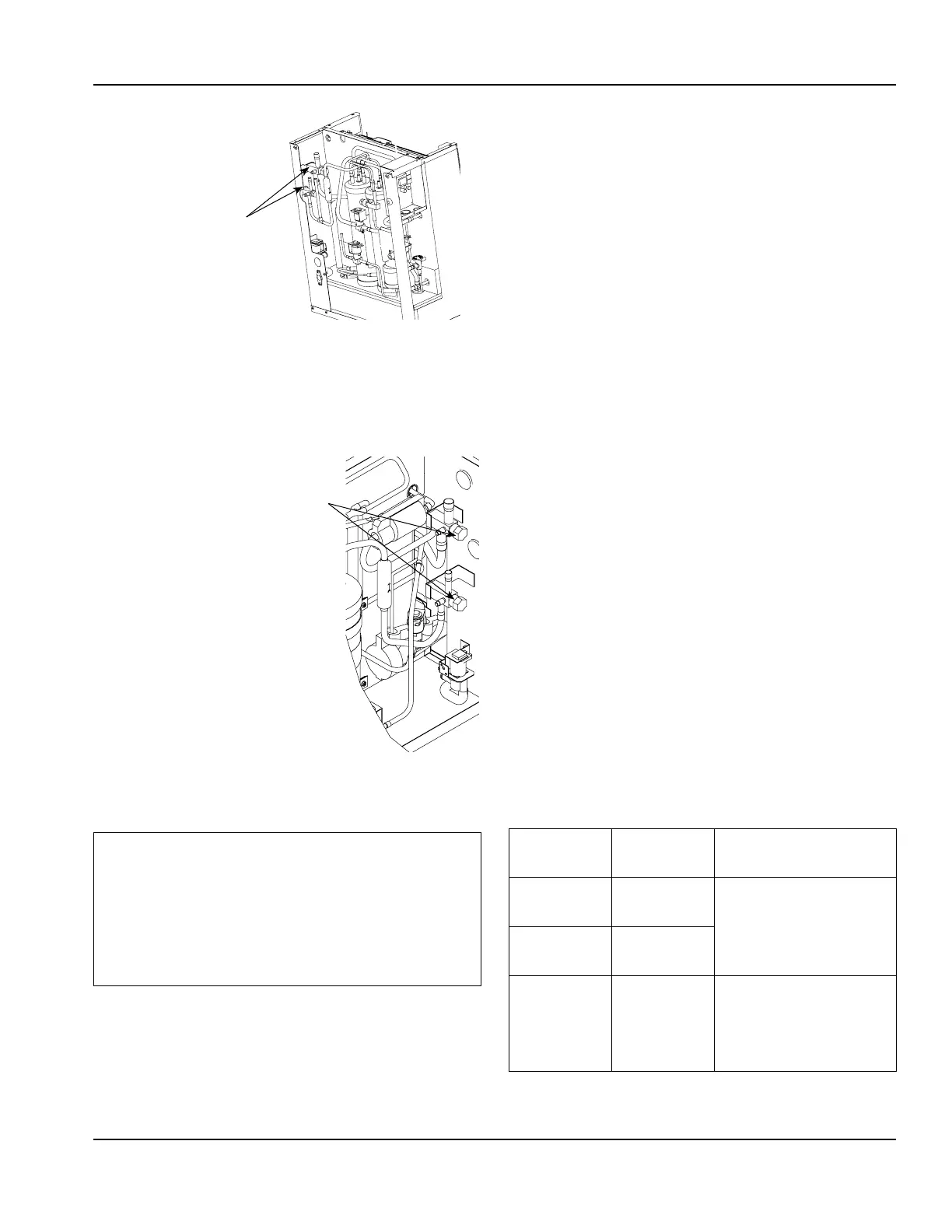

USE ALLEN WRENCH

TO OPEN (TURN

COUNTERCLOCKWISE)

SHUTOFF VALVES

FOR THE LIQUID AND

SUCTION LINES

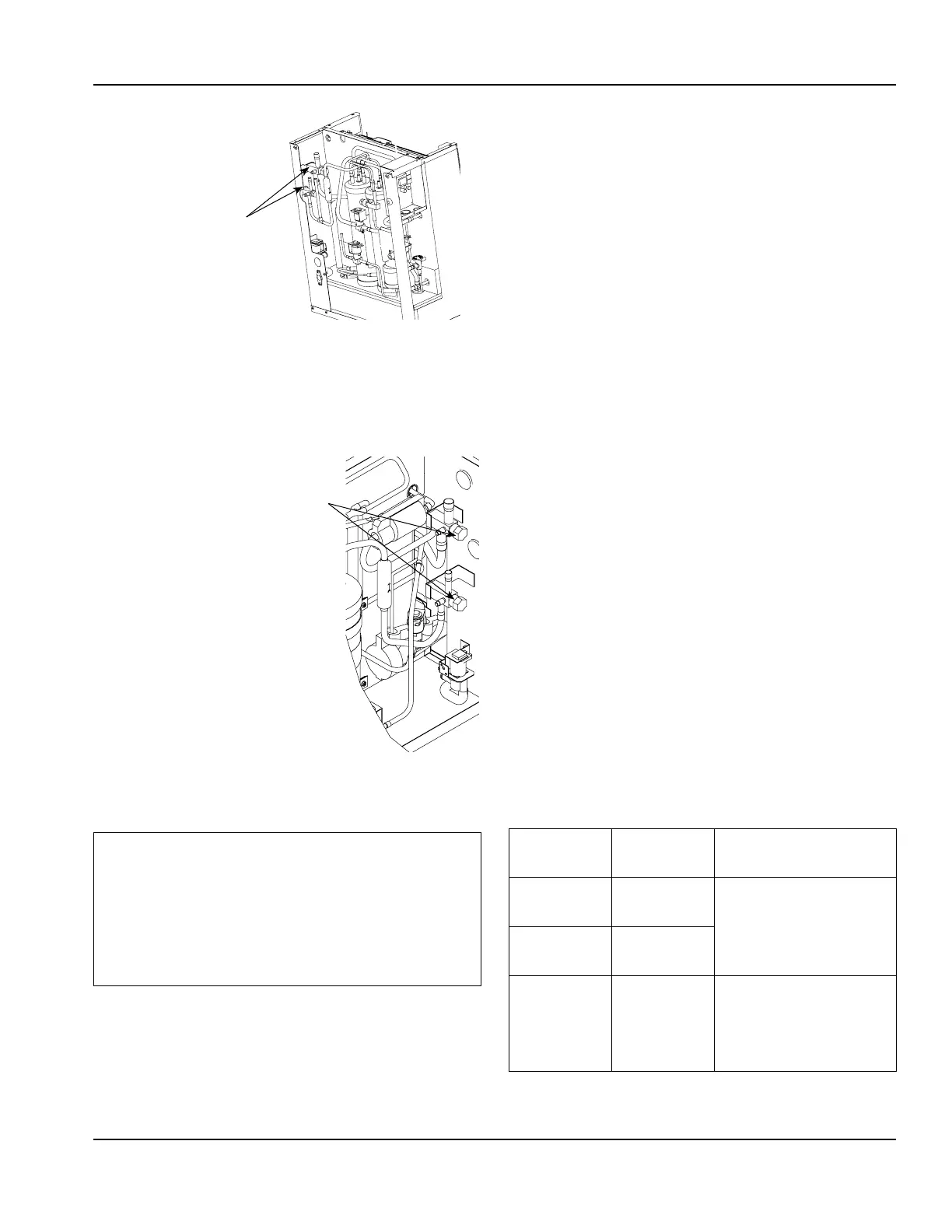

Ice Beverage Models

USE ALLEN WRENCH TO OPEN

(TURN COUNTERCLOCKWISE)

SHUTOFF VALVES FOR THE

LIQUID AND SUCTION LINES

IF1400C/IF1800C/IF2100C

IT1430C/IT1830C/IT2130C

Notice

After opening suction, discharge and

receiver service valves, refrigerant

pressure will not be detected until the

ice machine starts a freeze cycle and the

solenoid valves energize.

Step 5 Leak-Check the Refrigeration

System.

A. Connect power to the ice machine

head section - Do not connect

power to the CVD condensing unit.

B. Press the power switch and

energize the ice machine for

60 seconds to equalize pressures.

C. Disconnect power to the ice

machine head section.

D. Leak-check line set connections,

S trap and all factory joints in head

section and condensing unit.

E. Connect power to the CVD

condensing unit and allow system

to pump down.

Step 6 Insulation Requirements.

• To prevent condensation, the entire

suction line, including the shutoff valve,

must be insulated.

• All insulation must be airtight and sealed

at both ends.

• The following insulation requirements

prevent condensation at 90° F (32°C)

ambient temperature and 90% relative

humidity. If higher humidity is expected,

increase insulation thickness:

Suction

Line

Liquid

Line

Min. Insulation

Thickness

3/4 inch

(19 mm)

1/2 inch

(13 mm)

Suction Line -

1/2" (13 mm)

Liquid Line -

1/4" (7 mm)

5/8 inch

(16 mm)

3/8 inch

(10 mm)

3/4 inch

(19 mm)

5/8 inch

(16 mm)

Suction Line -

3/4" (19 mm)

Liquid Line -

1/4" (7 mm)

Loading...

Loading...