Part Number 020002365 08/25/2015 23

Section 2 Installation

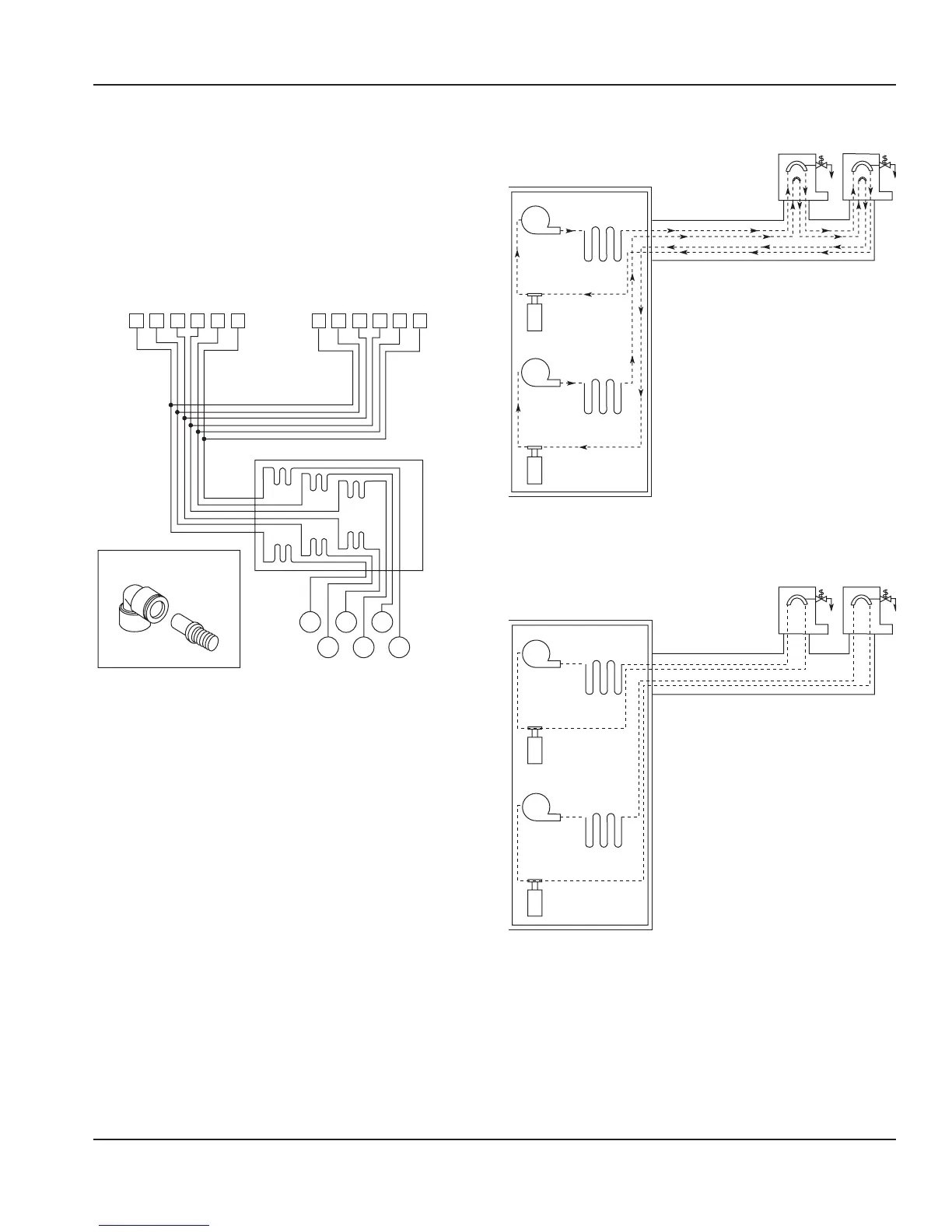

CONNECTING SUPPLY LINES

Pre-installation of towers is required and the appropriate

syrup supply must be connected to the corresponding

tower. The valves are numbered 1-6, 1-8, or 1-10 from left to

right viewing from the front of the tower.

1. For a two (2) tower installation, refer to the Syrup

Supply Line Diagram below. The syrup product supply

boxes can be positioned on a BIB rack in a convenient

location near the soda system.

“T”

John Guest to Adapter

Syrup

Supply

Syrup

Coils

Note: Some

provide more

capability.

6

531

42

Syrup Supply Line Diagram (Valve #6 Water Only)

NOTE: Refer to the optional equipment component

installation instructions for completion (if applicable) of the

beverage system. Do not connect the syrup supply at this

time.

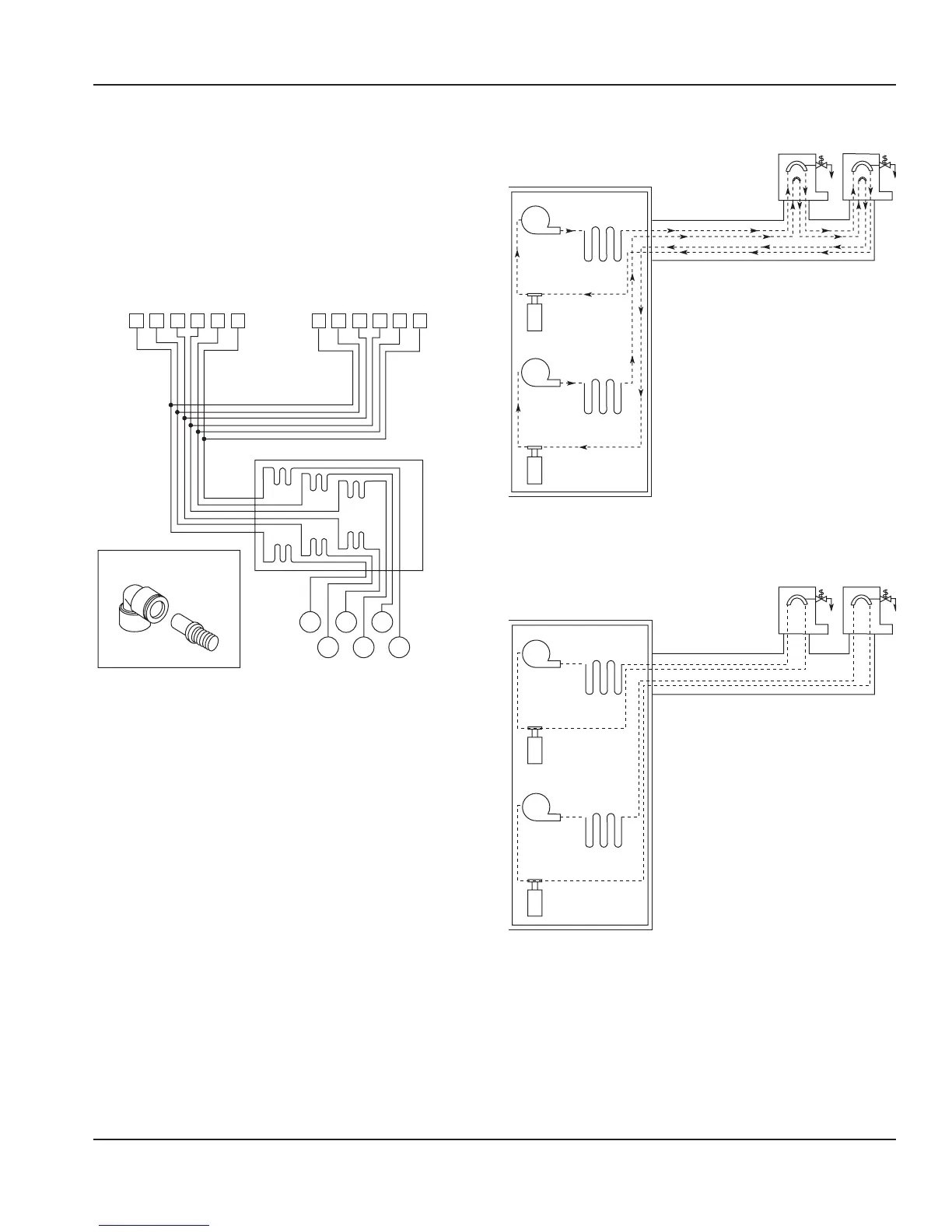

2. Locate the conduit supply lines for the refrigeration

unit. There are four (4) 1/2" (1.27 cm) carbonated

water lines marked in sets for the system. Connect

the yellow carbonated water supply line (7) to the

yellow carbonated water return line (A). Connect

the blue carbonated water supply line (8) to the

blue carbonated water return line (B). Refer to the

Carbonated Water Supply Line Diagram below.

Two Circulation Pumps – Two Circuits

Circ.

Pump

Carb.

Tank

Heat

Exchanger

Circ.

Pump

Carb.

Tank

Conduit

Conduit Tee

Refrigeration Unit

Heat

Exchanger

Blue

Yellow

Yellow

Blue

Interlaced Tower

Two Circulation Pumps – Two Circuits

Circ.

Pump

Carb.

Tank

Heat

Exchanger

Circ.

Pump

Carb.

Tank

Conduit

Conduit Tee

Refrigeration Unit

Heat

Exchanger

Non-interlaced Tower

Loading...

Loading...