15

TILLING (continued)

WARNING

•

DANGER

THE OPERATOR OF THIS

TILLER IS RESPONSIBLE FOR

ACCIDENTS OR HAZARDS

OCCURRING TO HIMSELF,

OTHER PEOPLE OR THEIR

PROPERTY.

! !

You Can Even Control Depth.

For Deeper Tilling:

Move your Tiller slowly back and forth, as

you would a vacuum cleaner. Work the same

area over and over until you’ve dug to your

desired depth. (Picture 3)

For Shallow Tilling:

Switch the tines to the cultivating position.

(See page 16 to learn

how.) Then move your

Tiller quickly over your

soil surface.

For Big Weeds or

Tough Roots:

Let your Tiller rock

back and forth over

the tough spot, until

the tines slice through

the weed or root.

Picture 3

Dry Weight . . . . . . .2.8kg — 6 lbs., 3 ounces

Type of Engine . . . .Air Cooled, Two stroke, Single-Cylinder,

Gasoline Engine

Rotation . . . . . . . . . .Clockwise, viewed from TOP

Bore . . . . . . . . . . . . .32.2 mm (1.268 in.)

Stroke . . . . . . . . . . .26.0 mm (1.04 in.)

Spark Plug . . . . . . . .NGK BPM8Y

Fuel Oil Ratio . . . . .50:1 ratio with MANTIS oil

Gasoline . . . . . . . . .Unleaded (see page 12)

Displacement . . . . .21.2 cc (1.294 cu. in.)

Exhaust System . . . .Spark arrester muffler

Carburetor . . . . . . . .ZAMA diaphragm model C1U type

Ignition System . . . .Flywheel magneto, capacitor discharge

ignition type

Starter . . . . . . . . . . .Automatic rewind with power spring assist

Oil . . . . . . . . . . . . . .Designated, two-stroke, air-cooled

engine oil

Fuel Tank Capacity .0.5 lit. (17.0 oz.)

ENGINE SPECIFICATIONS

SERVICE MAINTENANCE GUIDE

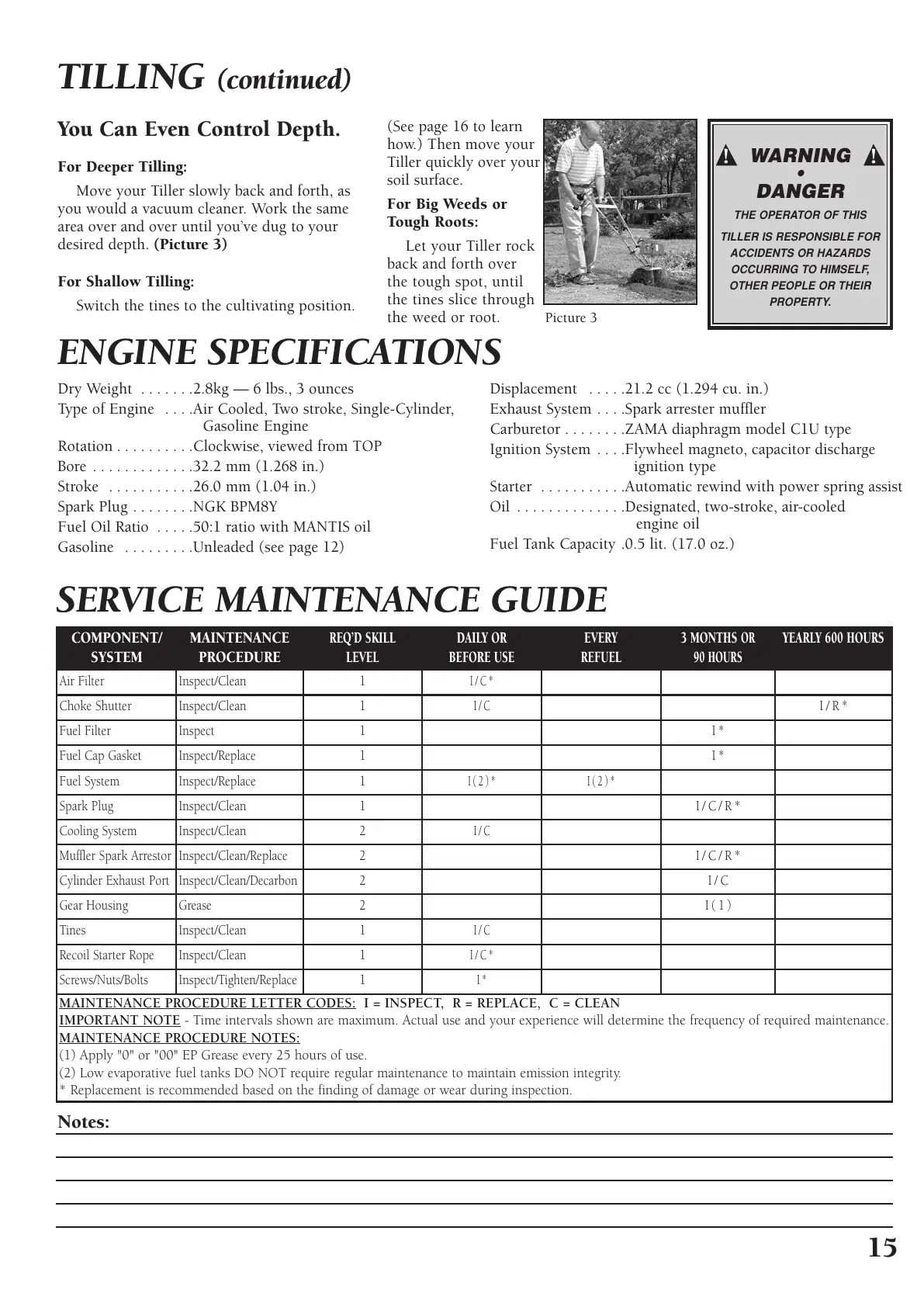

COMPONENT/

SYSTEM

MAINTENANCE

PROCEDURE

REQ’D SKILL

LEVEL

DAILY OR

BEFORE USE

EVERY

REFUEL

3 MONTHS

OR

90 HOURS

YEARLY 600 HOURS

Air Filter Inspect/Clean 1

I / C *

Choke Shutter Inspect/Clean 1

I / C

I / R *

Fuel Filter Inspect 1 I *

Fuel Cap Gasket Inspect/Replace 1 I *

Fuel System Inspect/Replace 1

I ( 2 ) * I ( 2 ) *

Spark Plug Inspect/Clean 1 I / C / R *

Cooling System Inspect/Clean 2

I / C

Muffler Spark Arrestor Inspect/Clean/Replace 2 I / C / R *

Cylinder Exhaust Port Inspect/Clean/Decarbon 2 I / C

Gear Housing Grease 2 I ( 1 )

Tines Inspect/Clean 1

I / C

Recoil Starter Rope Inspect/Clean 1

I / C *

Screws/Nuts/Bolts Inspect/Tighten/Replace 1

I *

MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN

IMPORTANT NOTE - Time intervals shown are maximum. Actual use and your experience will determine the frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Apply "0" or "00" EP Grease every 25 hours of use.

(2) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.

* Replacement is recommended based on the finding of damage or wear during inspection.

Notes:

Loading...

Loading...