2

d1

d1

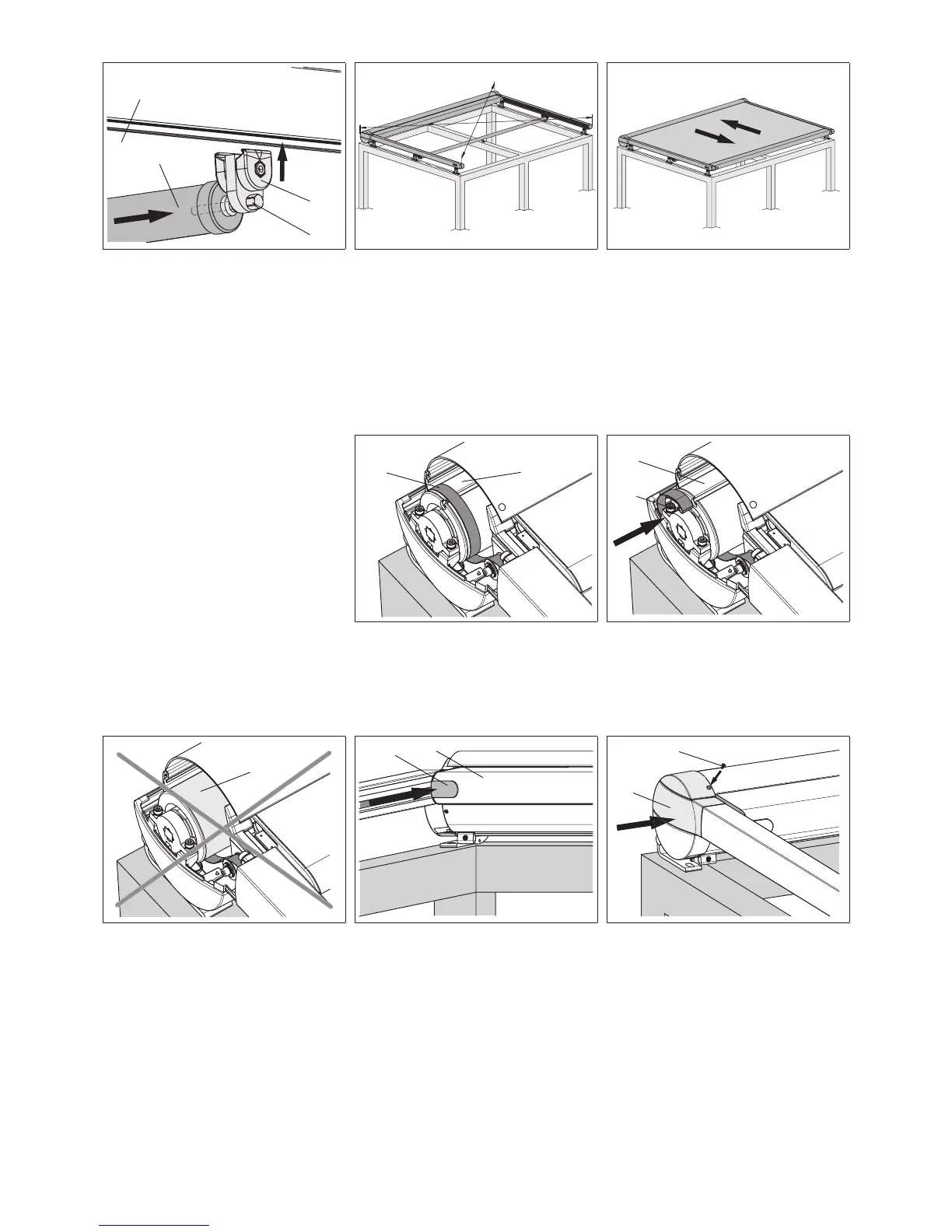

27. Slide the pin (26) of the right cover

support tube bracket (24) into the cover

support tube (28). Clip the bracket (24)

to the guide track (2) and tighten the

clamping jaws of the bracket with an SW

6 spanner.

28. Measure the awning diagonally (d1)

and align, as otherwise smooth functio-

ning is not guaranteed.

Attention! It is important that the

guide tracks are parallel. The max.

xture tolerance (in particular for the

tracx function) is 3 mm as otherwise

smooth operation cannot be guaranteed.

Subsequently tighten all screws of the

xture brackets.

29. Extend and retract the awning for

functional testing.

Attention! The lower end position is

not programmed for the standard

motor without radio. Take care that the

extension prole does not damage the

conservatory when moving the awning.

Make sure you stop before. See also

point 6. motor drive.

18

19

18

12

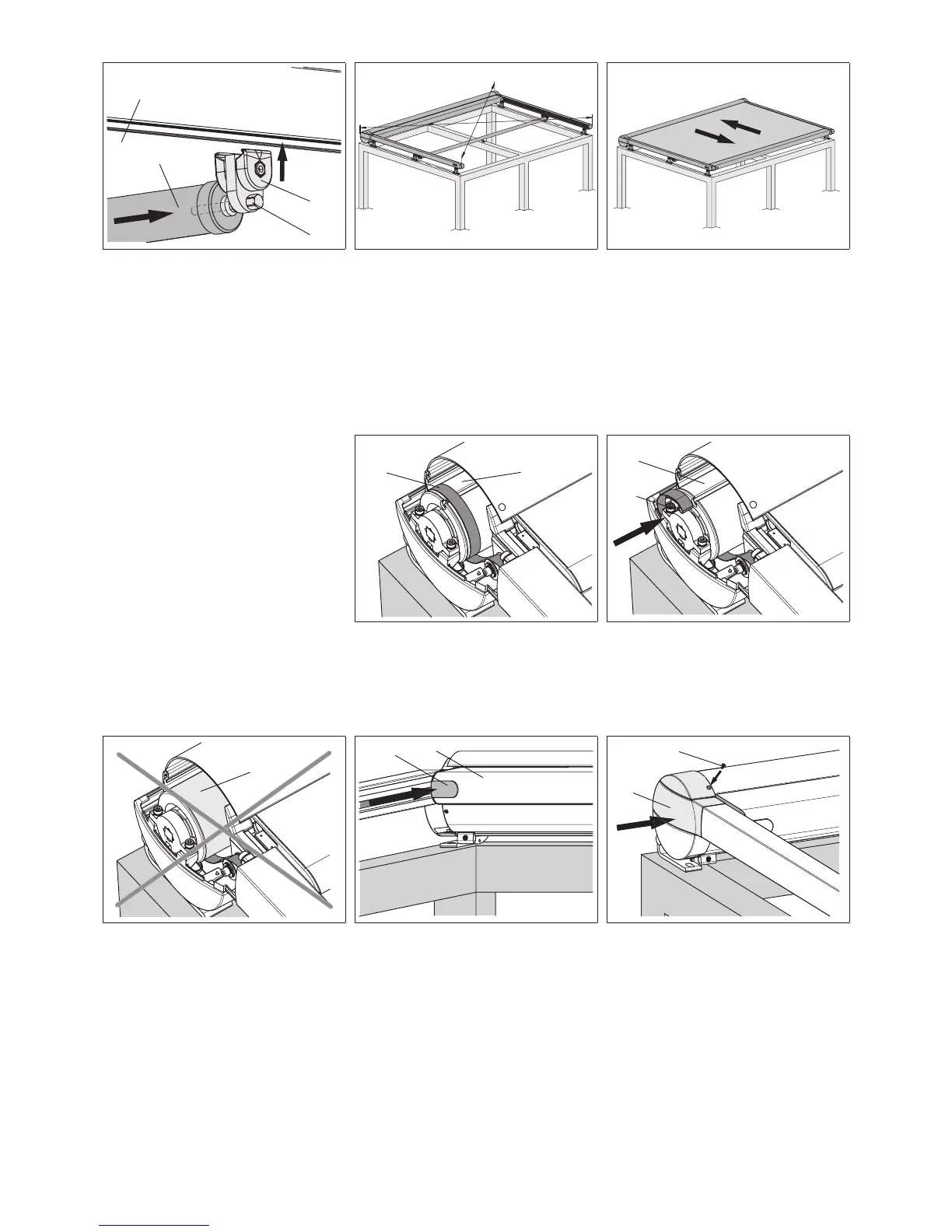

Attention! If the awning cloth has

enough tension in central position, see

chapter 4. What is to be done, if.... If the

position of the drive belt is incorrect, see

paragraphs 30. to 32.

30. Check the position of the drive belt

(19) on the fabric roller (18) when the

awning is retracted. Ideally, the fabric

roller will be in the position shown. The

transport band envelops the fabric roller

with 1.5 wrappings.

31. If, when the rst wrap of the drive

belt has been unwound, the lug in the

drive belt (12) is in the upper area of the

fabric roller (18), then trouble-free

operation of the awning is still guaran-

teed.

18

32. Should there be no drive belt left on

the fabric roller (18), paragraphs 9. to

15. have to be repeated. For this

purpose the gas piston has to be

secured again as described in chapter 4

"What to do, if....".

33. Roll up the drive belt together with

the length of velcro, insert it into the front

prole (20) and put on the end cap (21)

(on both the right and the left).

34. On both end caps x the inspection

covers again (9) using the countersunk

head screws (8).

Loading...

Loading...