headline bars

continuation tabs

notes

warnings

headline bars

continuation tabs

notes

warnings

headline bars

continuation tabs

notes

warnings

headline bars

continuation tabs

notes

warnings

headline bars

continuation tabs

notes

warnings

headline bars

continuation tabs

notes

warnings

16

model no. 5742 | contact us 1-800-689-9928

OPERATING INSTRUCTIONS

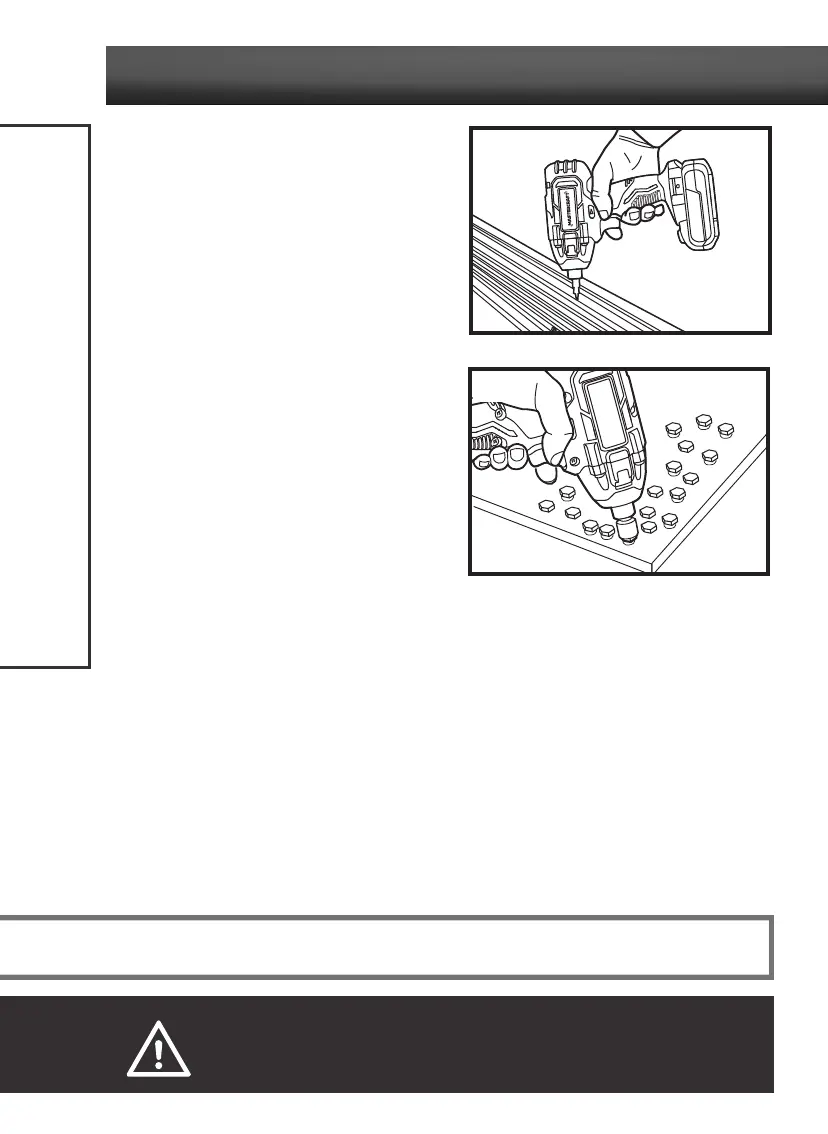

TIGHTENING SCREWS OR NUTS

(fig 9/fig 10)

1. Install the correct bit/socket.

2. Apply just enough pressure to keep the bit/

socket engaged on the screw or nut.

3. Position the direction-of-rotation selector to the

left of the tool for forward rotation.

4. Apply minimal pressure to the variable-speed

trigger switch initially. Increase the speed only

when full control can be maintained.

LOOSENING SCREWS AND NUTS

(fig 9/fig 10)

1. Install the correct bit/socket.

2. Apply just enough pressure to keep the bit/socket

engaged on the screw or nut.

3. Position the direction-of-rotation selector to the

right of the tool for reverse rotation.

4. Apply minimal pressure to the variable-speed

trigger switch initially. Increase the speed only

when full control can be maintained.

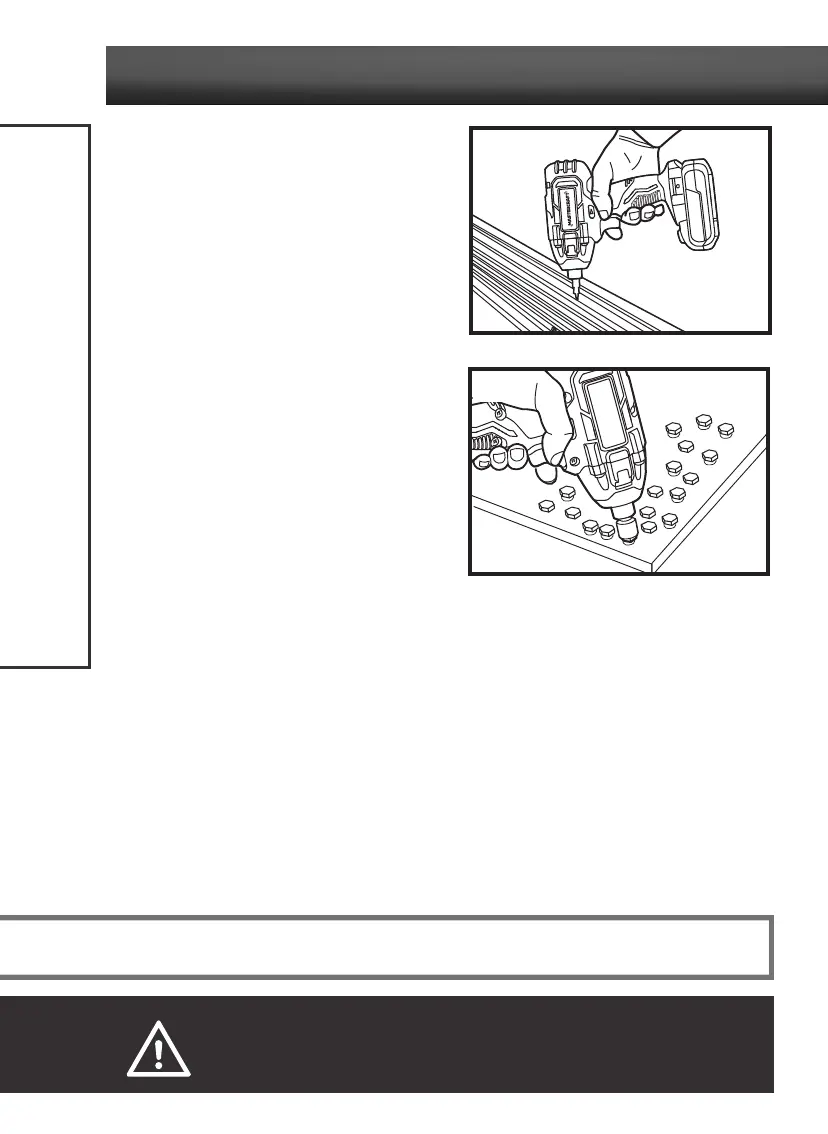

TIGHTENING TORQUE

The fastening torque is affected by a wide variety of factors including the those listed below. After

fastening, always check the torque with a torque wrench.

Voltage: Low voltage, due to a nearly discharged battery, will reduce fastening torque.

Socket size: Failure to use the correct socket size will cause a reduction in fastening torque.

Bolt size: Larger bolt diameters generally require higher fastening torque. Fastening torque will also

vary according to length, grade, and torque coefficient.

Bolt: Ensure that all threads are free of rust and other debris to allow proper fastening torque.

Material: The type of material and surface finish of the material will affect fastening torque.

fig 10

fig 9

NOTICE: Before starting your job, always perform a test operation to determine the proper fastening time.

WARNING!

• Do not over-tighten, because the force of the impact driver can break the fastener. Keep the impact driver

pointed straight at the fastener to avoid damaging the fastener head.

Loading...

Loading...