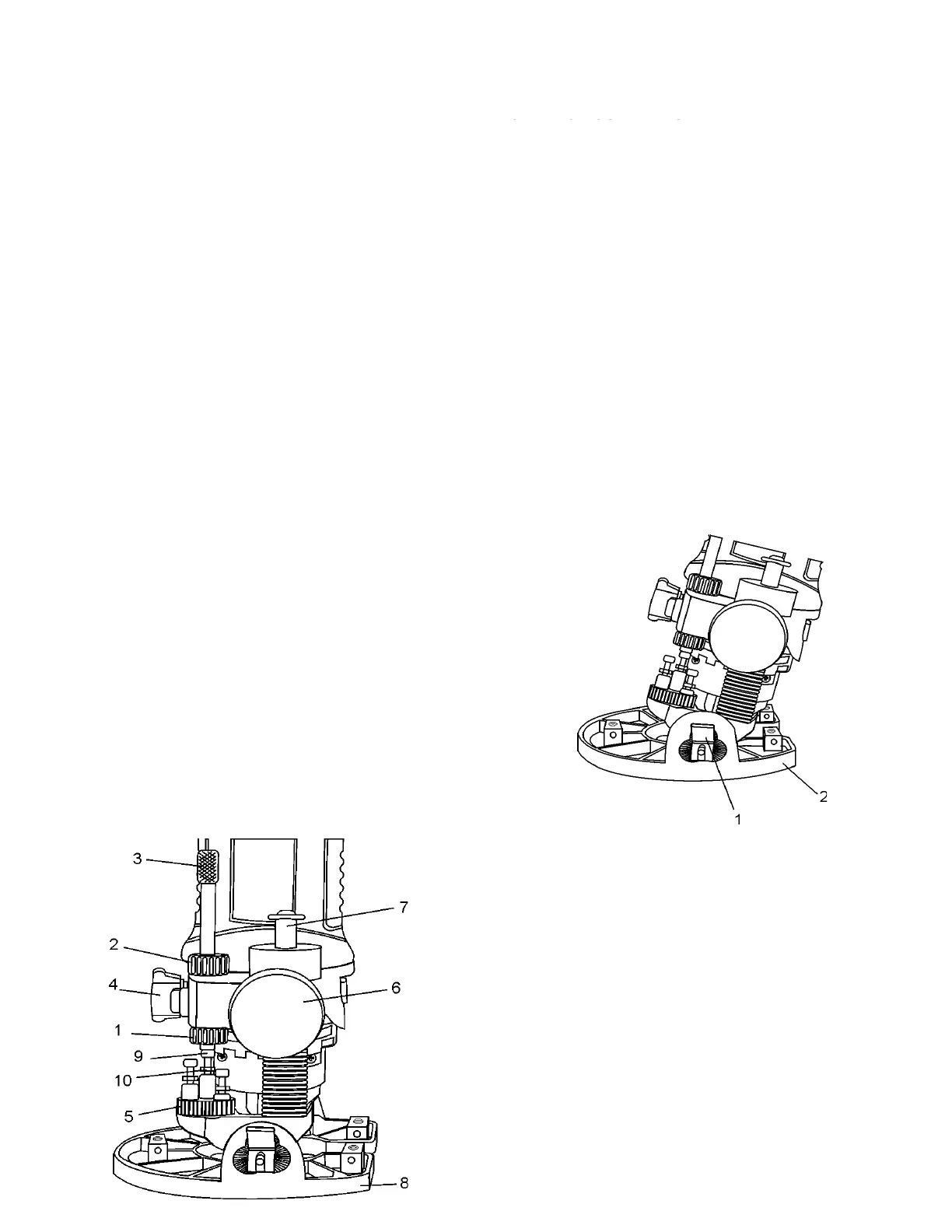

SETTING PLUNGE DEPTH – cont’d

4. Loosen both height adjusting knobs (6) by turning

them counter-clockwise.

NOTE: Only loosen height adjusting knobs enough to

release the tension on the guide rods (7).

5. Slide router base (8) up or down to obtain the desired

depth of cut.

6. Re-tighten height adjusting knobs when the desired

cut depth is reached.

7. Push the depth stop quick release button and lower

depth stop rod until it contacts the step turret stop

screw (9). After releasing the quick release button,

finer adjustments can be made by turning the depth

stop rod.

8. Lock both the lower (1) and upper (2) depth stop lock

nuts against the router body to lock the depth stop rod

in place.

NOTE: Do not use pliers to tighten lock nuts. Turn lock

nuts by hand only.

9. Lock shortest step turret stop screw by tightening lock

nut (10).

NOTE: Do not over tighten lock nut.

10. Loosen both height adjusting knobs just enough to

allow router to freely slide up and down on the guide

rods.

11. Two additional depths can be pre-set in a similar way

setting the other two step turret stop screws to the

desired depth.

NOTE: To select pre-set plunge depth, simply rotate

the step turret until the correct turret stop screw is

aligned under the depth stop rod.

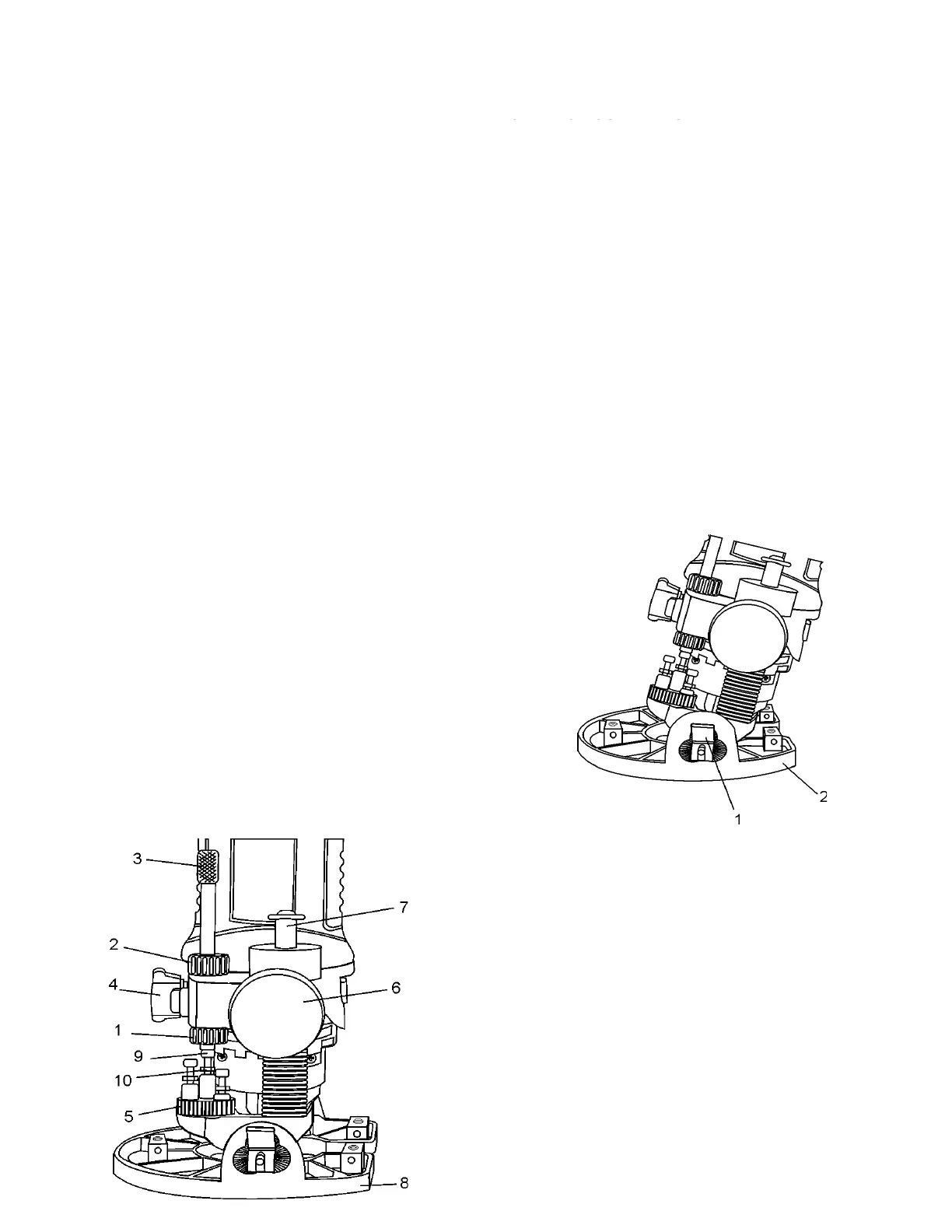

SETTING ROUTER BASE BEVEL

Bevel cutting with the cutting bit can be done with the

router base tilted to the desired angle.

1. Loosen both bevel adjusting locks (1) by pulling them

outward from the router base (2) (see Fig. 18).

2. Tilt router base to the desired angle.

NOTE: There are detents for locking the router base

at 0

o

, 15

o

, 30

o

and 45

o

. These are the four most

common angles for bevel cutting.

3. Lock both bevel adjusting locks by pushing them firmly

back into position against the router base.

4. Check bevel angle between router base and router bit

to ensure they are at correct angle.

5. Check router depth of cut and re-set the depth if

required.

NOTE: Depth of cut will usually have to be increased

after tilting the router base for bevel cutting.

Loading...

Loading...