OPERATING INSTRUCTIONS

31

MIG 180 INVERTER WELDER 058-9306-4

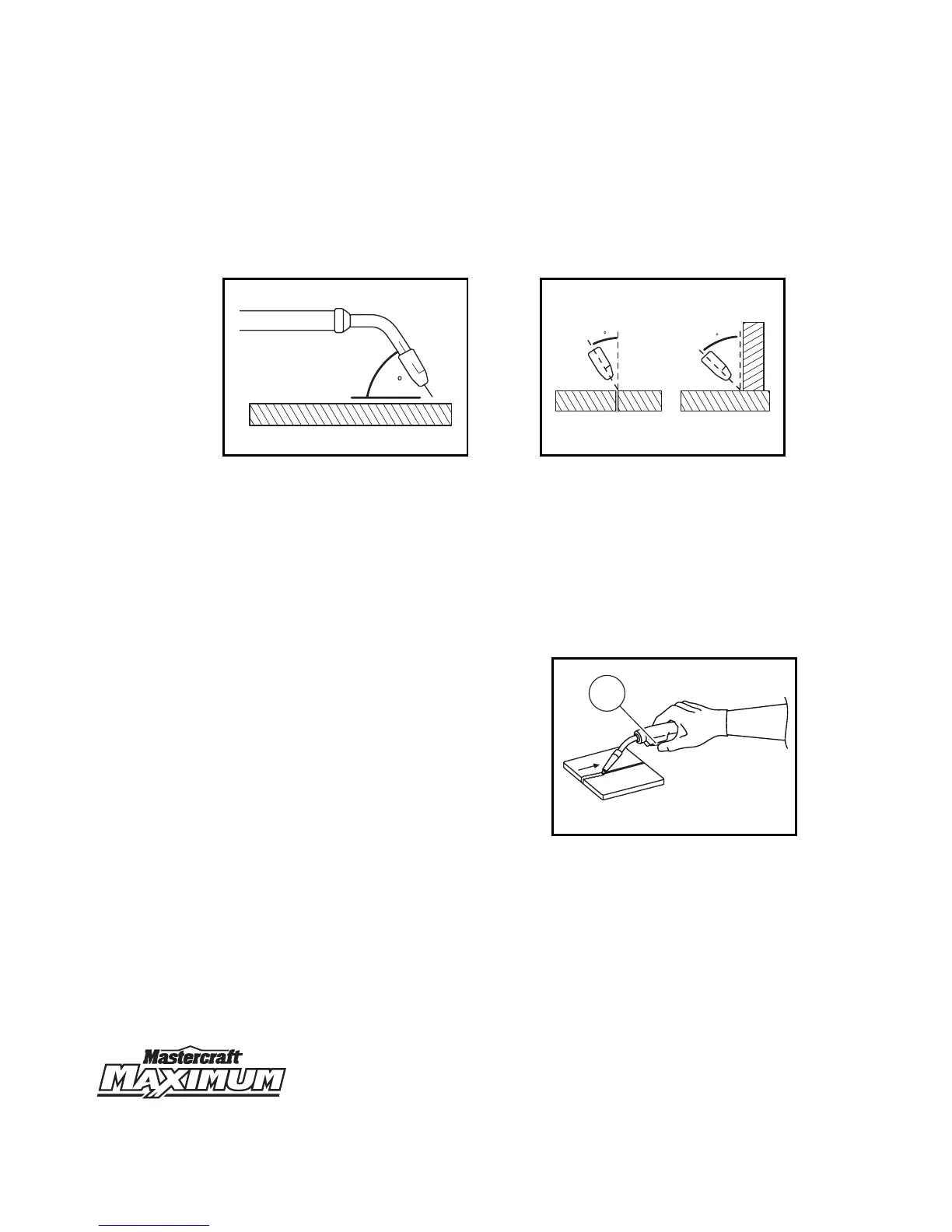

There are two angles of the torch nozzle in relation to the work piece that must be considered when

welding.

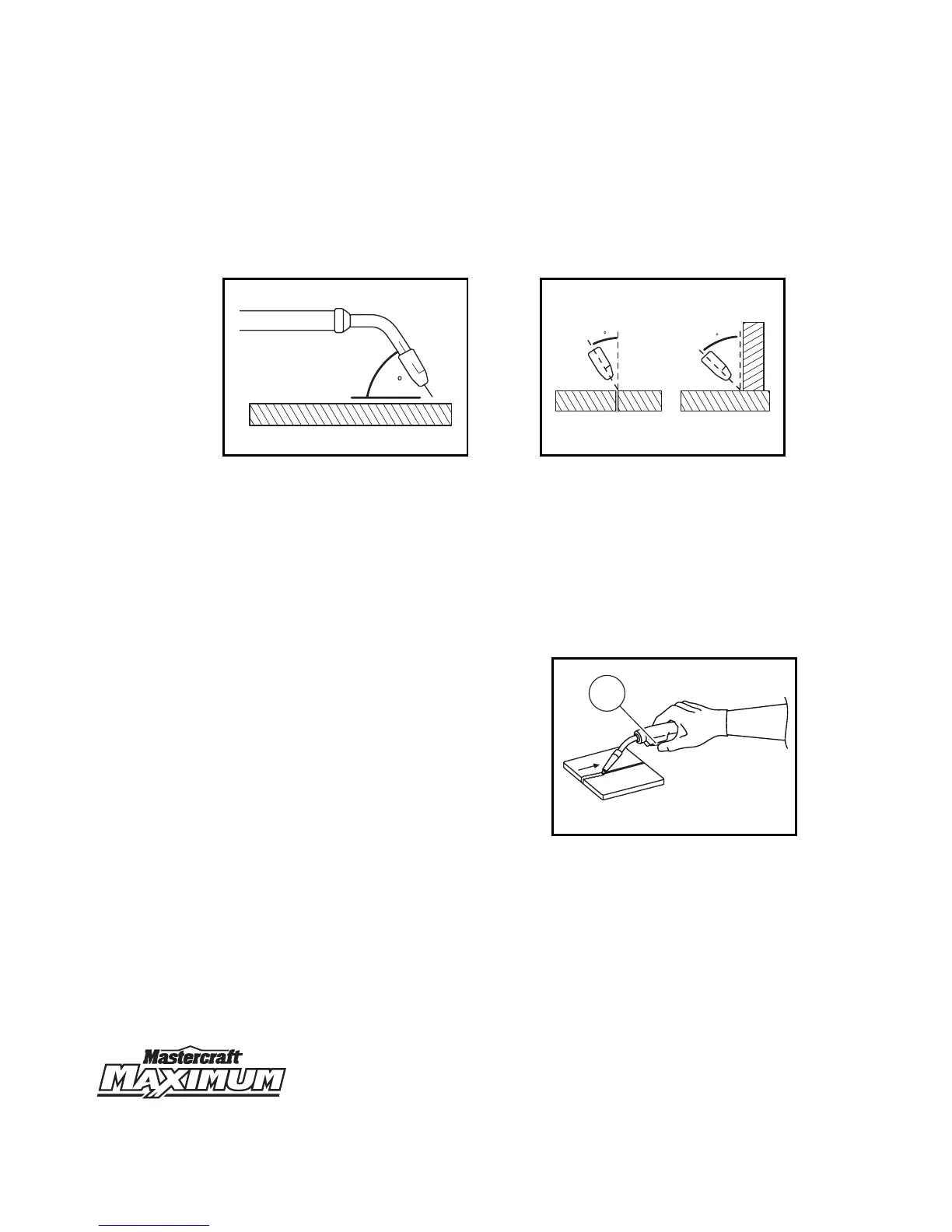

4. Turn the wire feed speed control with

the other hand to its maximum position

and continue to hold onto the speed

control.

5. Pull the trigger (1) on the torch to start an

arc. Drag the torch toward the user while

simultaneously turning the wire feed

speed control counterclockwise

(fig 2G)

.

6. When the wire speed decreases, the sound that the arc makes will change from a sputtering

sound to a high-pitched buzzing sound. The correct setting is the point where the high-pitched

buzzing sound is achieved. Use the wire feed control to slightly increase or decrease the heat

and penetration by selecting higher or lower wire feed settings.

Repeat the above steps 1-5 if a new wire speed, a different diameter wire or a different type of

welding wire is selected.

Angle A (60 degrees) Angle B (30-45 degrees)

• Angle A is the angle between the nozzle

and the work piece and can be varied, but

in most cases the optimum angle will be

60 degrees (the point at which the torch

handle is parallel to the work piece). If

angle A is increased, penetration will

increase, and if decreased penetration

will decrease

(fig 2E)

.

• Angle B is the angle between the

perpendicular of the work piece and the

nozzle and can be varied to improve the

visibility of the arc in relation to the weld

puddle and to direct the force of the arc

(fig 2F)

.

60

fig 2E

MC-589306-40

30

45

fig 2F

MC-589306-41

MC-589306-42

1

fig 2G

Loading...

Loading...