IMPORTANT INFORMATION

13

MIG 180 INVERTER WELDER 058-9306-4

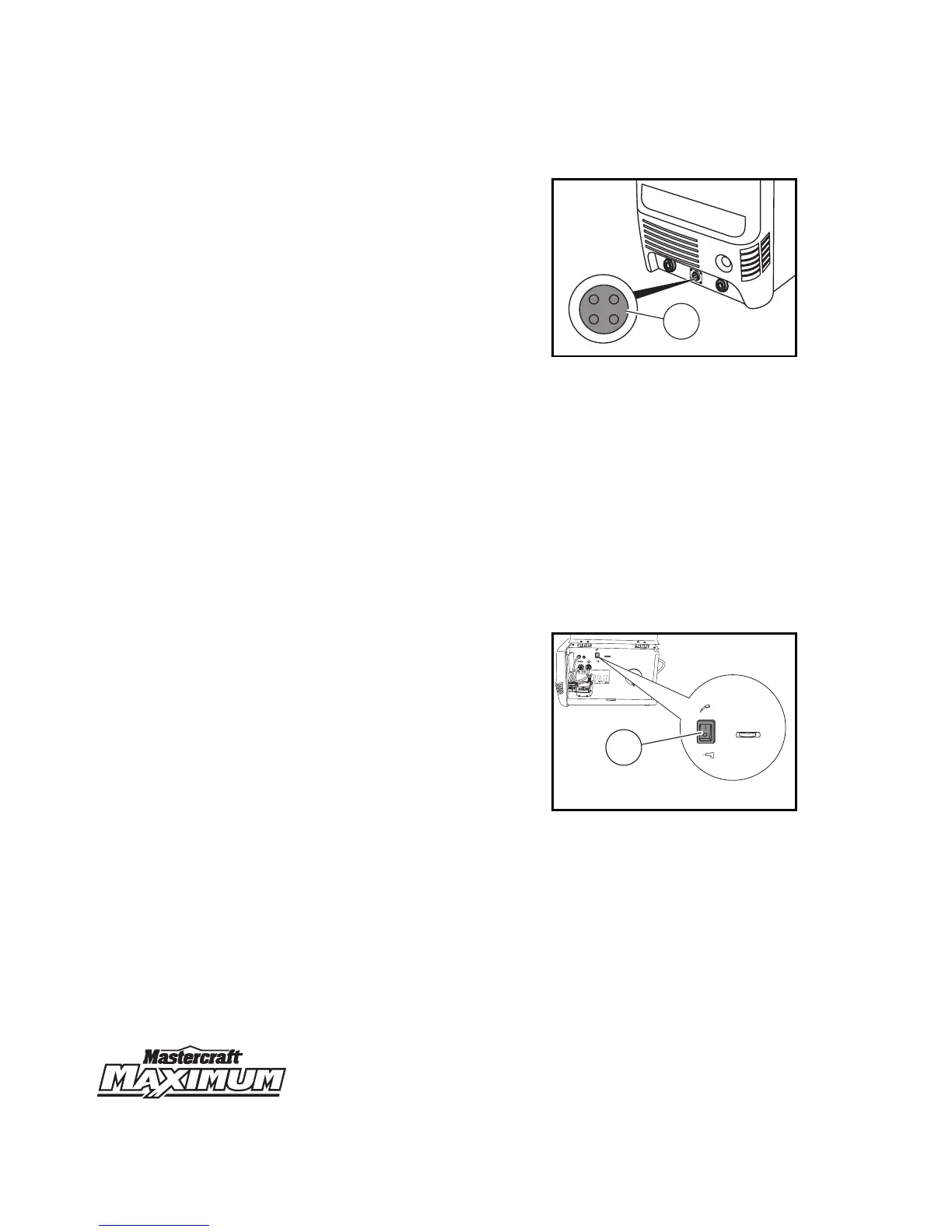

MIG gun trigger connection

This MIG gun trigger connection (1) is located

in the lower front panel and connects the 4-pin

quick connect plug of the MIG gun or the spool

gun (not included) with the welding unit.

Connections 1 and 2 are provided for the MIG

gun/spool gun and connections 3 and 4 are

provided for the wire feed motor.

Mode selector switch

This switch is located on the upper front panel of the welder and is used to select either MIG

welding mode or stick welding mode.

Power ON indicator

This indicator is located on the upper front panel of the welder and glows when the primary power

plug is connected to the power supply and the switch is turned ON.

Primary power switch

This switch is located on the back panel of the welder and enables to turn the welding unit ON or OFF.

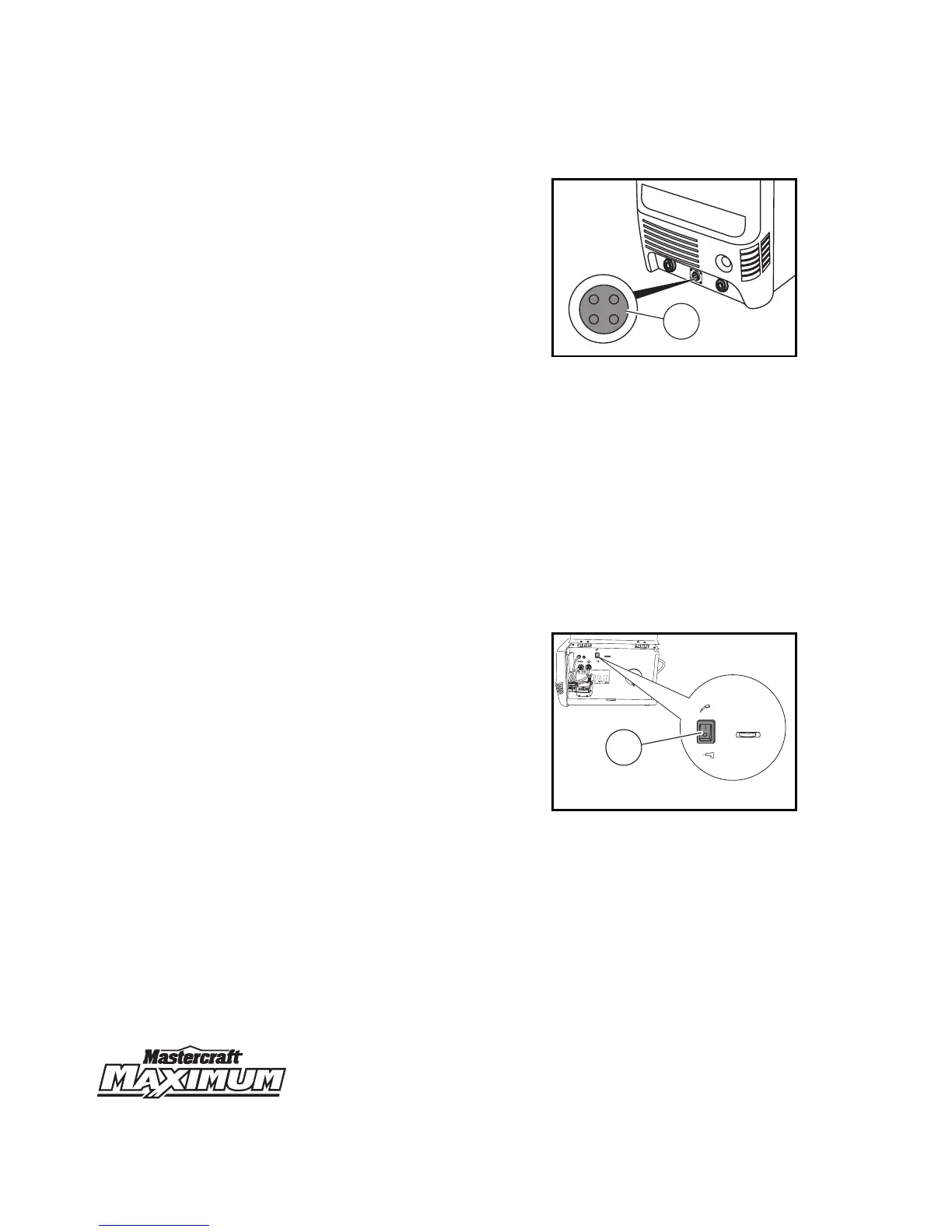

Spool gun selector

The spool gun selector (1) is located inside the

wire compartment. This selector is switched to

spool gun mode when an optional spool gun

(not included) is being used, otherwise it stays

in the MIG mode. Refer to spool gun’s manual

for its connection instructions.

Thermal overload indicator

This indicator is located on the upper front panel of the welder and glows when the thermal overload

circuit is activated. The welding unit stops working during this period protecting the unit from any

damage. The cooling fan of the welding unit continues to work even if the welding unit is shut down

by the thermal overload circuit.

12

3

4

MC-589306-35

1

MIG 180 INVERTER WELDER

SOUDEUSE À ONDULEUR MIG 180

WARN

IN

G /

AV

ER

TI

S

SEM

E

N

T

E

L

ECTRIC

SHOCK

c

a

n

k

ill

U

N C

H

O

C

É

L

EC

TR

IQUE

p

e

ut t

u

er.

MOUING PAR

TS

c

a

n

ca

u

se i

n

j

u

ry.

LE

S

P

IÉC

E

S

MO

BILE

S

p

euvent c

a

us

e

r d

e

s

b

l

e

ss

ur

es.

•

W

e

l

di

ng wi

r

e an

d

dri

v

e part

s

m

ay

be

at

w

el

d

i

n

g

v

o

l

t

ag

e.

•

Keep

aw

a

y fro

m

m

o

v

i

ng p

ar

t

s

.

•

Ne

v

o

u

s

appr

oc

he

z

p

as

d

es

piè

ces

m

ob

i

l

e

s

.

•

M

ai

n

t

en

ez

t

o

us

l

es

co

uv

ercl

es,

p

an

neau

s

e

t p

orte

s

f

erm

és

et

s

o

l

i

dem

e

n

t

e

n

p

lac

e

.

•

Keep

al

l

do

o

rs,

c

overs

a

n

d p

an

el

s

cl

o

s

ed

a

n

d

s

ecu

r

el

y

i

n pl

ac

e

.

• Le

fi

l

d

e s

o

udu

r

e et

l

e

s

pi

èces

m

o

t

r

i

ces

s

o

n

t

peu

t

-ê

t

re

a l

a

tens

i

o

n de s

o

udag

e.

• N

e tou

ch

ez p

a

s

l

e fil

o

ules

parti

es

mo

t

r

i

c

e

s à m

a

in

s

n

ues

o

u

av

ec de

s

o

u

til

s

l

o

rs

que l

a det

en

t

e es

t s

o

u

s

,

p

r

es

s

i

o

n.

•

D

o

not

to

uch

wi

r

e

or drive parts

wi

t

h

b

ar

e h

a

n

d

s

or

to

o

l

s

w

hen

t

r

i

g

g

e

r

i

s

depr

e

ss

ed.

MIG

SPOOL GUN/PISTOLET À BOBINE

When normal MIG welding,

this switch should be turned in “MIG” positio

n.

when using spool gun

.

this switch should be in “

Spool gun” position.

Ce commutateur doit être placé à la position «

MIG »

si vous effectuez du soudage MIG normal

et à la p

osit

ion « SPOOL GUN »

si vous utilisez un pistolet à bobine

.

D

CEN

D

CE

N

FL

UX

COR

E

WIRE

FIL AVE

C ÂME

EN

FL

U

X

C

ou

r

a

nt

con

t

inu

po

la

ri

t

é no

r

ma

le

P

ol

a

rit

y

sw

it

c

h

se

t

tin

g

:

R

é

g

la

ge

du

c

o

mmut

a

t

e

u

r de polarit

é

:

D

i

r

e

ct

c

urrent

, e

lec

t

ro

d

e

nagat

i

ve

DC

E

P

DC

EP

M

IG

M

IG

D

i

rect cu

rren

t

,

el

ectro

de po

s

i

ti

ve

C

o

ur

an

t co

nt

in

u

, el

ectro

d

e

p

o

s

i

ti

v

e

P

o

l

ari

t

y

s

w

i

t

c

h

s

etti

n

g

:

Rég

l

a

g

e du

co

m

mu

tateu

r d

e

p

ola

ri

té

:

S

T

ICK

BAGUETTE

P

o

l

ari

t

y

sw

i

tch

se

ttin

g

:

R

é

glag

e

d

u c

om

mu

ta

t

e

u

r

d

e

p

o

larité

:

+

+

+

-

-

-

NO

GAS/P

A

S DE G

A

Z

G

A

S

/GA

Z

MIG

SPOOL GUN/PISTOLET À BOBINE

When normal MIG welding,

this switch should be turned in “MIG” position.

when using spool gun.

this switch should be in “Spool gun” position.

Ce commutateur doit être placé à la position « MIG »

si vous effectuez du soudage MIG normal

et à la position « SPOOL GUN »

si vous utilisez un pistolet à bobine.

1

Loading...

Loading...