OPERATING INSTRUCTIONS

39

MIG 180 INVERTER WELDER 058-9306-4

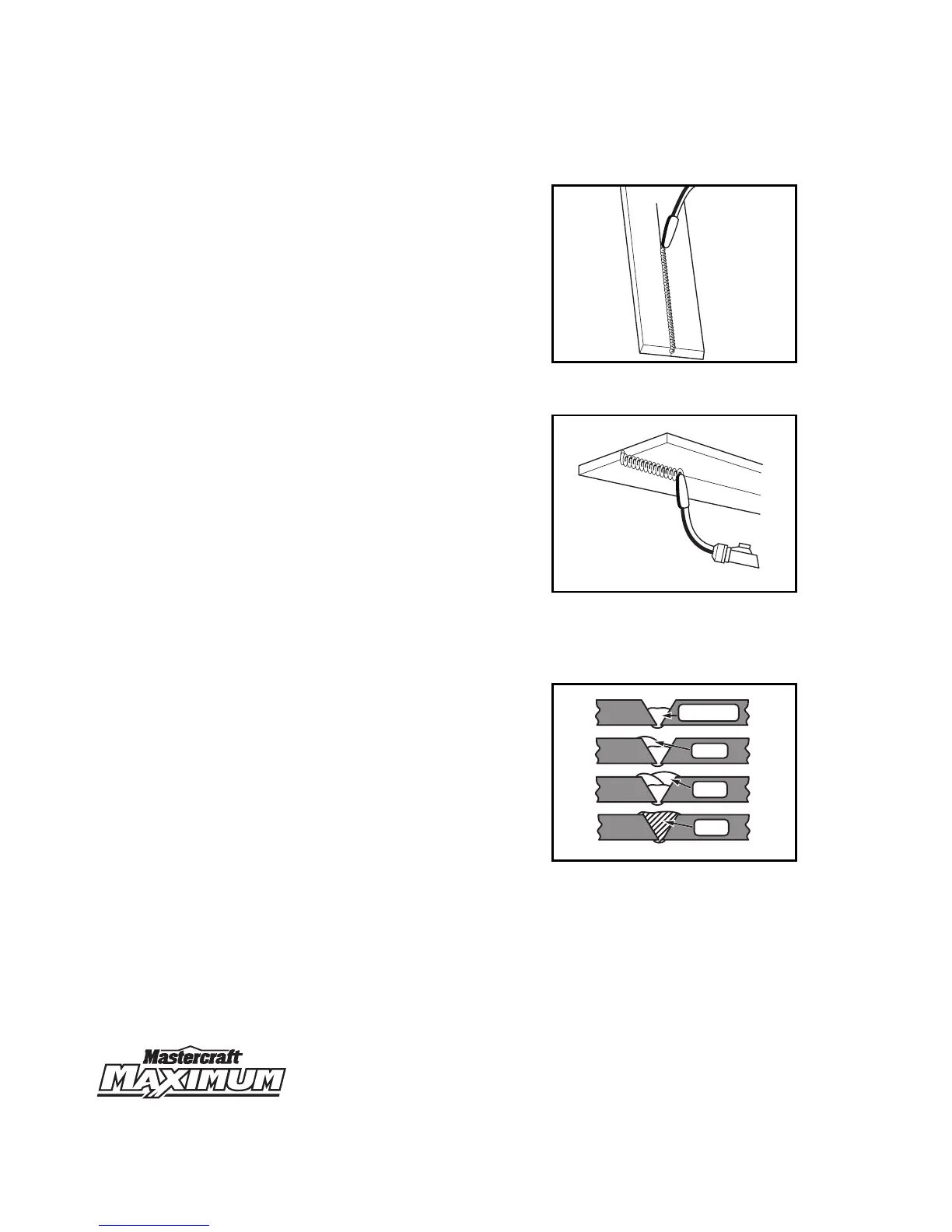

3. Vertical position: The torch can be easily

moved from top to bottom in this

position, though it is difficult to prevent

the puddle from running downward.

Moving the torch from bottom to top

provides better puddle control and

allows slower rates of travel speed to

achieve deeper penetration. For this

position, angle B should be zero and

angle A will vary from 45 to 60 degrees

to provide better puddle control

(fig 2V)

.

4. Overhead position: This is the most

difficult welding position. For this

position, angle A should be maintained

at 60 degrees

. Maintaining this angle

will reduce falling of molten metal into

the nozzle

(fig 2W)

.

Angle B should be zero so that the wire

is aiming directly into the weld joint. If

excessive dripping of the weld puddle

occurs, select a lower heat setting.

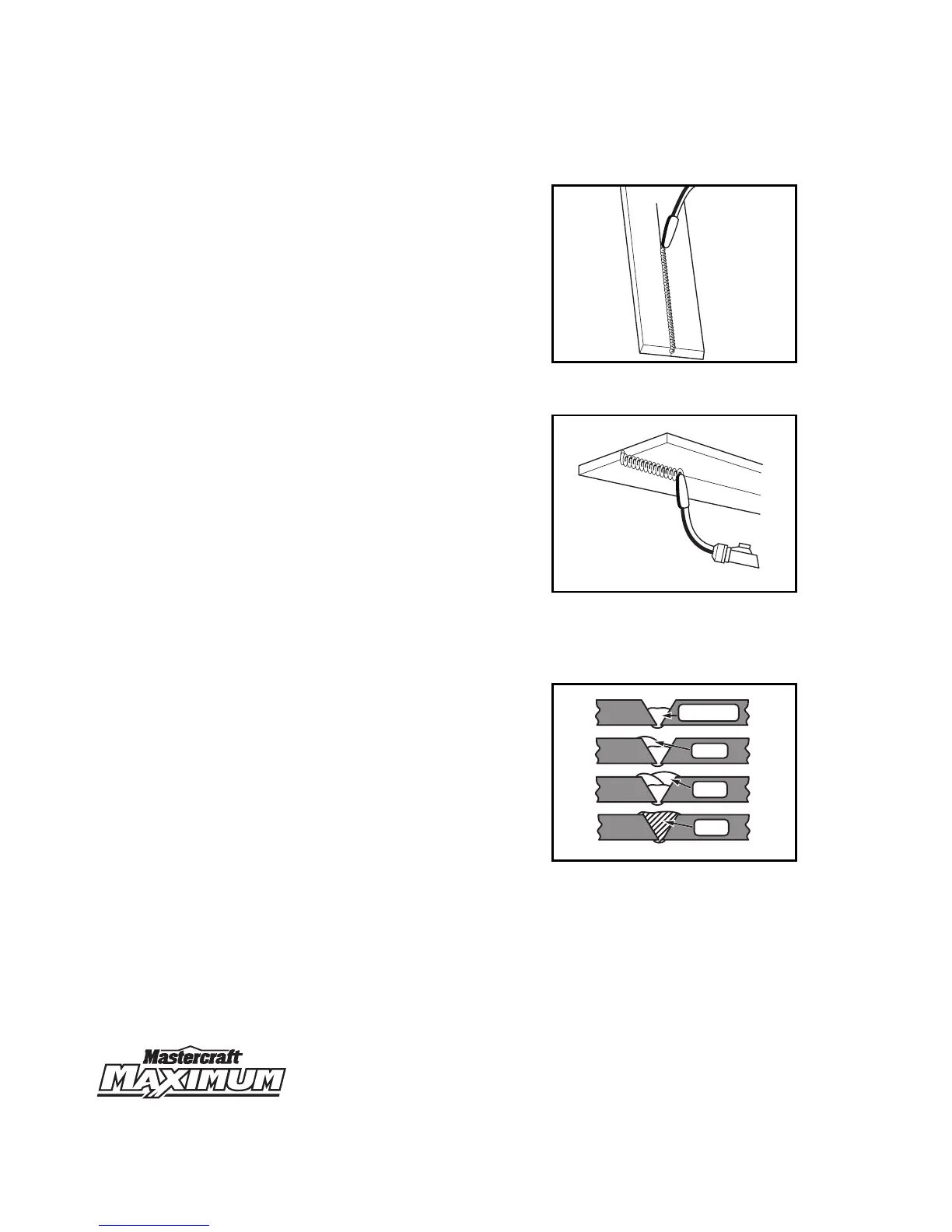

Multiple pass welding:

1. Butt weld joint: When butt welding

thicker materials, prepare the edges of

the material to be joined by grinding a

bevel on the edges of the metal pieces

being joined. When this process is done,

a "V" is created between the two metal

pieces. In most cases, more than one

pass or bead will need to be laid into the

joint to close the "V"

(fig 2X)

.

Note: When using self-shielding flux core wire,

it is necessary to thoroughly chip and brush the

slag off each completed weld bead before

making another pass.

fig 2V

MC-589306-57

fig 2W

MC-589306-58

fig 2X

1

2

1

1

23

First or

Root Pass

Second

Pass

Third

Pass

Finished

Weld

MC-589306-59

Loading...

Loading...