OPERATING INSTRUCTIONS

40

MIG 180 INVERTER WELDER 058-9306-4

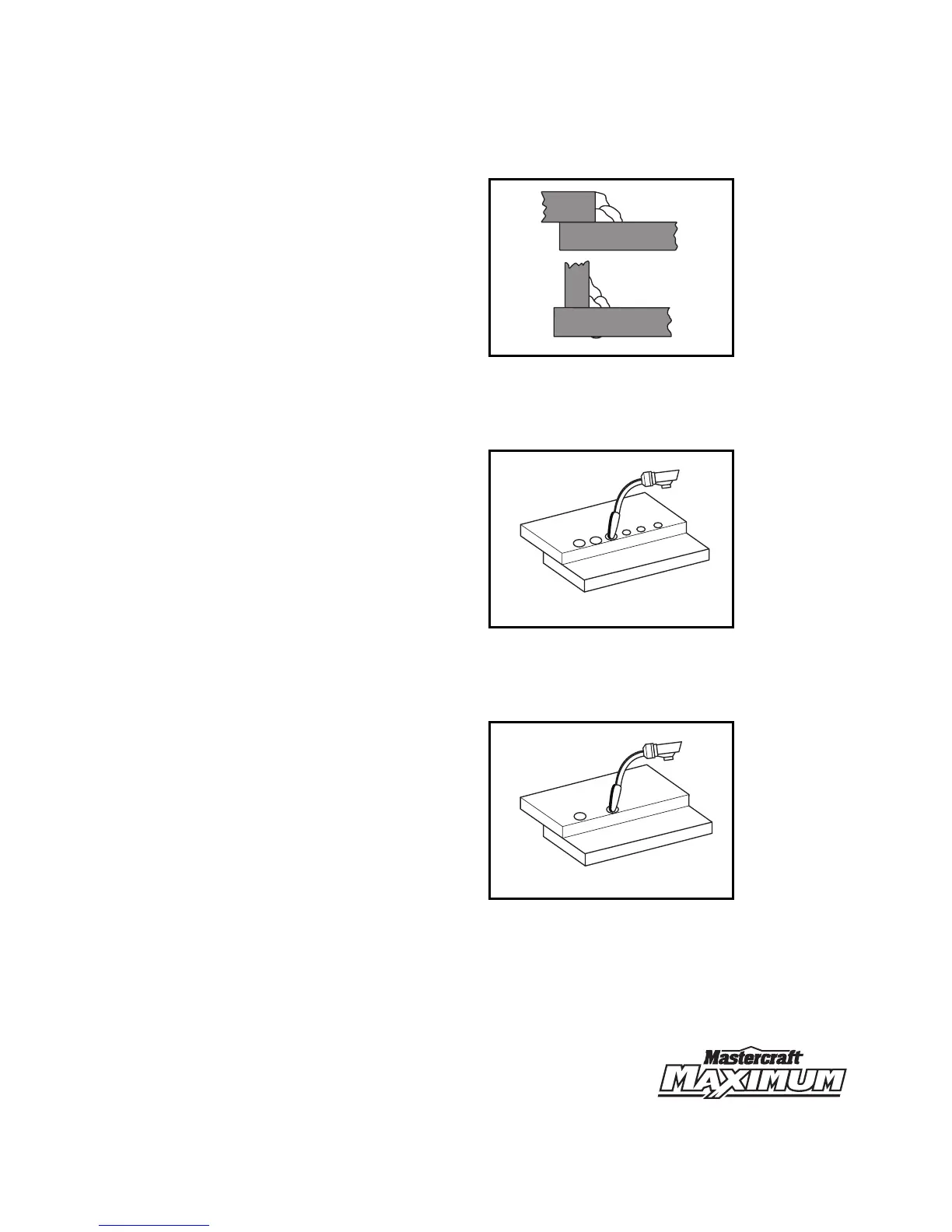

2. Fillet weld joint: Most fillet weld joints on

metals of moderate to heavy thickness

will require multiple pass welds to

produce strong joint. The multiple pass

beads can be laid in three passes into a

T fillet joint and a lap fillet joint

(fig 2Y)

.

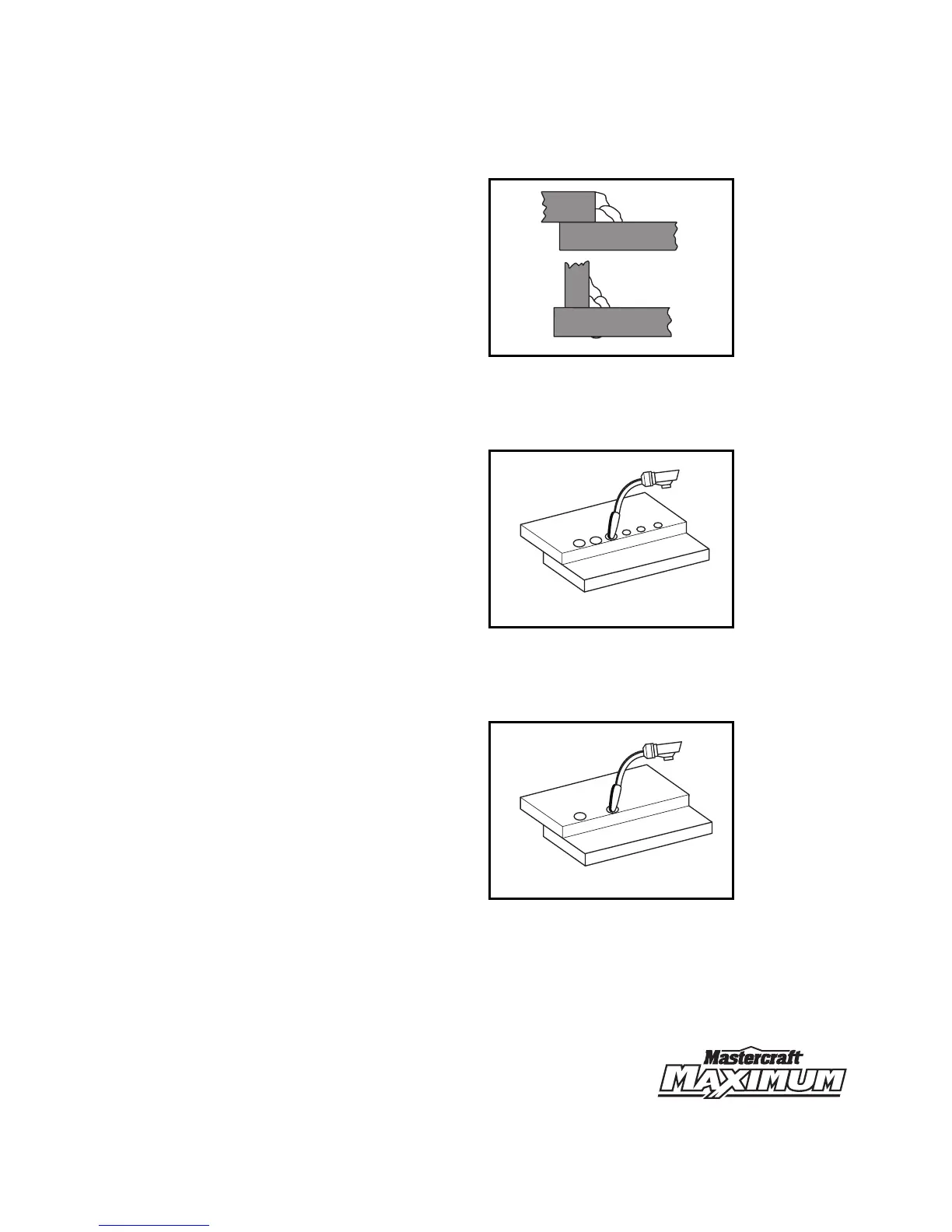

Spot welding:

There are three methods of spot welding:

1. Burn-through method: In this method,

two overlapped metal pieces are welded

together by burning through the top

piece and into the bottom piece.

Self-shielding, flux core wire of 0.035"

is suitable for this method. Always select

the high heat setting for this method and

tune in the wire speed prior to making a

spot weld

(fig 2Z)

.

Note: Do not use 0.030" self-shielding flux

core wires when using this method unless the

metal is very thin or excessive filler metal and

minimal penetration is acceptable.

2. Punch and fill method: In this method, a

hole is punched or drilled into the top

piece of metal and the arc is directed

through the hole to penetrate into the

bottom piece. The puddle is allowed to

fill up the hole leaving a spot weld that

is smooth and flush with the surface of

the top piece

(fig 3A)

.

fig 2Y

1

1

2

3

2

3

Lap Joint Welded

In Three Passes

T Joint in

Three Passes

MC-589306-60

fig 2Z

MC-589306-61

fig 3A

MC-589306-62

Loading...

Loading...