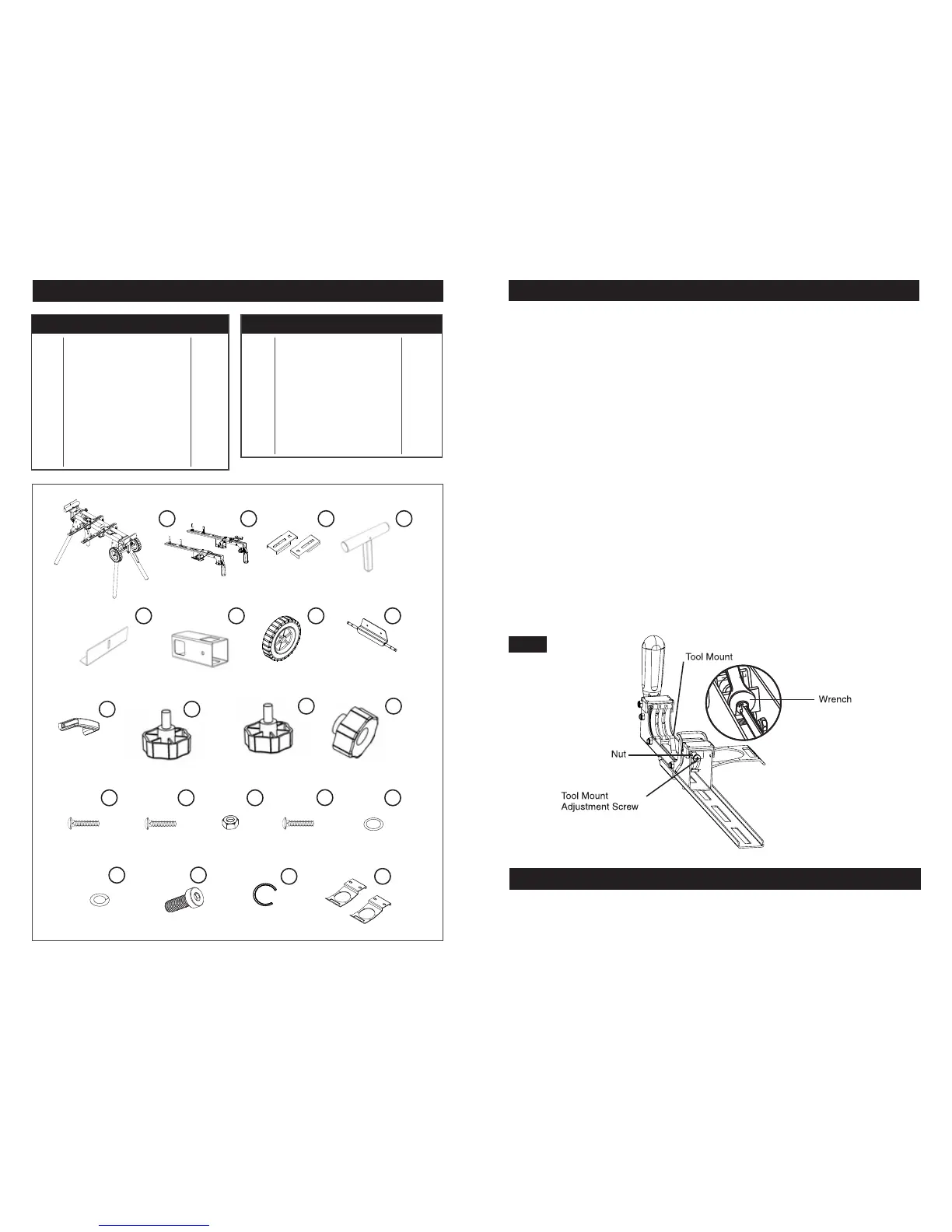

PARTS LIST

MITER SAW STATION

RAPID CLAMP TOOL MOUNT

OFFSET MOUNTING BRACKETS

MATERIAL SUPPORT

WORK STOP

MATERIAL SUPPORT RECEIVER

WHEEL

AXLE PLATE

HANDLE

KNOBS M8*35

KNOBS M8*25

1 pcs

2 pcs

2 pcs

2 pcs

2 pcs

2 pcs

2 pcs

1 pcs

1 pcs

2 pcs

4 pcs

1

2

3

4

5

6

7

8

9

10

11

KNOB NUTS M6

CARRIAGE BOLT M8*55

CARRIAGE BOLT M8*20

NUT M8

CARRIAGE BOLT M8*60

WASHER #8

SPRING WASHER #8

BOLT M8*25

C-CLIP

STORAGE HANDLES

2 pcs

2 pcs

6 pcs

14 pcs

4 pcs

14 pcs

14 pcs

4 pcs

4 pcs

2 pcs

12

13

14

15

16

17

18

19

20

21

PART # DESCRIPTION QTY

1

5

2 3 4

6 7 8

9

10

11

12

13 14 15

19

20 21

16

17

18

ASSEMBLY INSTRUCTIONS

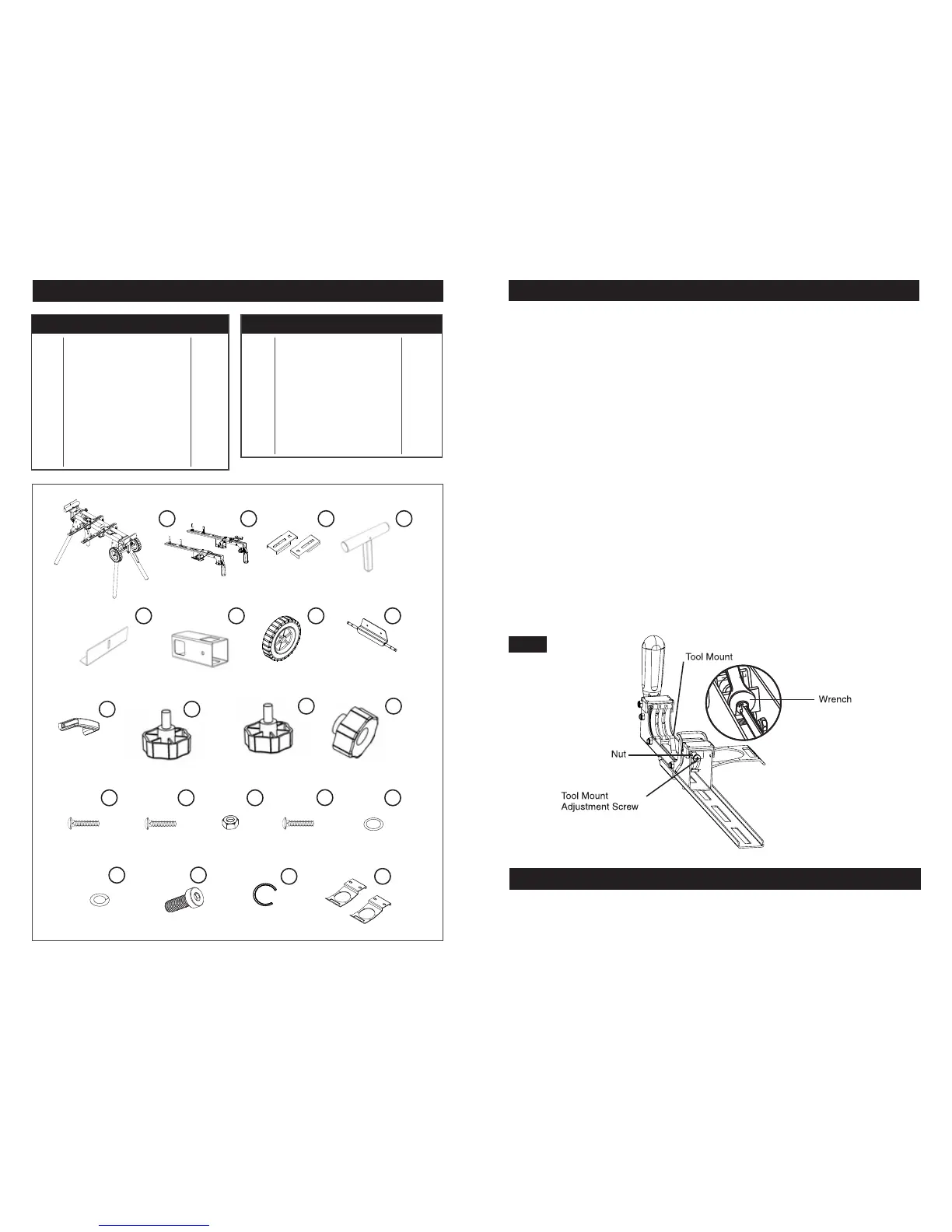

TOOL MOUNT ADJUSTMENT SCREW

TO ADJUST

Most plastic tool mounts are designed to fit snugly over the stand rails. With the locking levers in

the lowered (locked) position, you should not be able to remove the saw and tool mount

assembly from the rails. If the saw and tool mount can be removed from the rails when the levers

are locked, the tool mount adjustment screws need to be tightened. If the saw and the tool

mount assembly will not fit over both rails, the bracket adjustment screws needs to

be loosened.

NOTE: The saw should be removed from the tool mounts before attempting to tighten or

loosen the tool mount adjustment screws.

Figure 13.

1. Use a wrench to slightly loosen the nut.

2. Turn the screw with a Phillips screwdriver. Rotate clockwise if the tool mount assembly needs

to be tightened or counterclockwise if the assembly needs to be loosened.

3. Install the tool mount on the Contractor Miter Saw Station rails and lower the locking

lever to check the adjustment.

4. When the correct position is achieved, tighten the nut with a 10mm open-ended wrench

to secure.

5. Repeat steps 1 through 4 to attach the second tool mount.

FIG 13

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage

from various types of commercial solvents and may be damaged by their use. Use clean cloths

to remove dirt, dust, oil, grease, etc.

Page 3 Page 12

PART # DESCRIPTION QTY

Loading...

Loading...