en

8

| AC442 |

1901016-85

2.5

Safety devices

Description Function

Pressure

switch

Switches the compressor off in the normal operating

pressure is exceeded

Safety valve The safety valve opens if the design pressure is

exceeded

Circuit

Breaker

Interrupts the power supply if overcurrent is applied to

the AC442

Vents The AC442 is provided with vents in the housing to

ensure the exchange of air even when switched off.

2.6

Proper disposal

At the end of its service life, this equipment must

be disposed of as follows:

— Contact the service center to have the refrigerant

in the unit recovered and recycled.

— Consign the unit to an authorized collection

center according to local legislation.

2.7

Recycled material disposal

—

Return the refrigerant recovered from

the unit to the refrigerant supplier for

proper disposal or recycling.

— Lubricants extracted from the vehicle's

A/C system must be returned to an

official oil collection center

2.8

Packaging disposal

Electronic and electrical A/C service

equipment must never be disposed of with

domestic waste, but recycled

appropriately.

— The packaging must be disposed of in

conformity with local legislation.

— This contributes to protecting the

environment

2.9

Disposal of combo filter

—

Dispose of the filter via official

collection points or in accordance with

the local regulations. This contributes

to protecting the environment

2.10

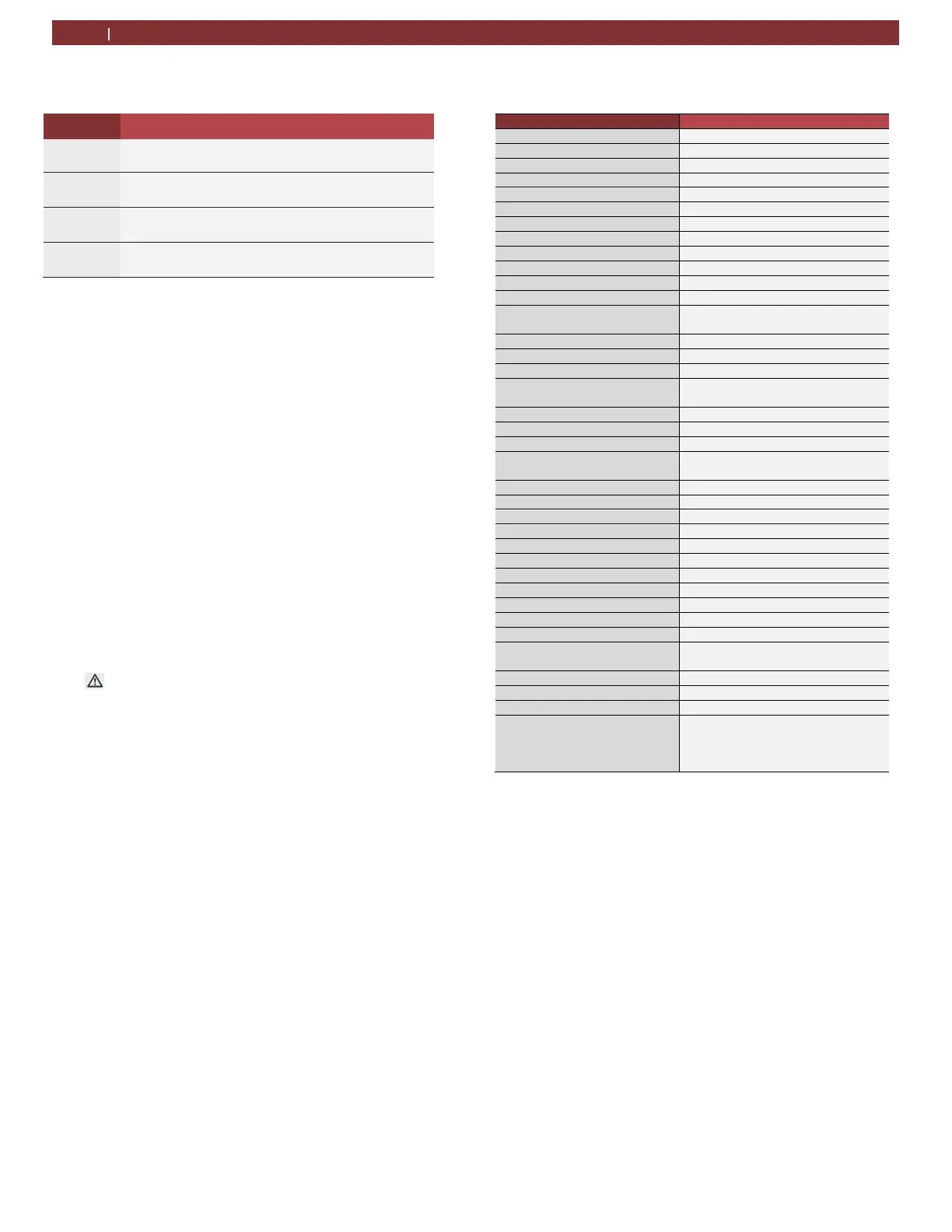

Technical Data

Description Specification

R134a tank capacity 12L

Service pressure 400PSI

Maximum content 22lbs.

Method to weigh gas content Load cell

Recovered oil container 250ml

Vacuum pump 2CFM dual stage

Vacuum pump oil quantity 250ml

Compressor capacity 0.87cu in/14cc

Dryer filter 90kg recovered R134a

Non-condensable gas purge Automatic via solenoid valve

HP and LP taps Automatic

Display 7 inch capacitive touch screen

Software updating

USB type A or USB type B direct

connect to PC

Printer (optional) Thermal, 24 columns

All functions Automatic and manual

Recycling mode Single pass

Memory for customized

cycles

100 records

Flushing With integrated solenoid valves

System pressure diagnostics Manual and automatic

Dryer filter replacement alarm Active

Vacuum pump oil

replacement alarm

Active

Full/empty tank check alarm Active

Full oil container check alarm Visual

Empty oil container alarm Visual

Dimension H x W x D 119 x 74 x 74 cm

Dry weight 98kg

Power supply frequency 60Hz

Voltage 120VAC, 1 phase

Total max load 7.5A

Overcurrent protection 12A (circuit breaker)

Operating temperature 50 - 122°F

Humidity 10 90%RH (non-condensing)

Storage temperature and

humidity

-13 to 50°F

10 - 90%RH (non-condensing)

Max operating altitude 6562 ft.

Pollution degree 2

Water degree 0

Certifications

SAE J2788

UL 1963

CAN/CSA STD C22.2NO. 120 –

M91

2.11

Glossary

Recovery phase: The refrigerant is extracted from the

vehicle air conditioning system, cleaned and routed into the

internal bottle of the AC442. The refrigerant oil collected in

the process is drained into the used oil bottle at the AC442.

Vacuum phase: A vacuum is generated in the vehicle air

conditioning system. Measurement of the drop in pressure

begins as soon as the vacuum has been generated.

Charging phase: A certain quantity of refrigerant is added

to the vehicle air conditioning system.

Loading...

Loading...