Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless

testing requires power.

December 2003 16022846 Rev 0

3

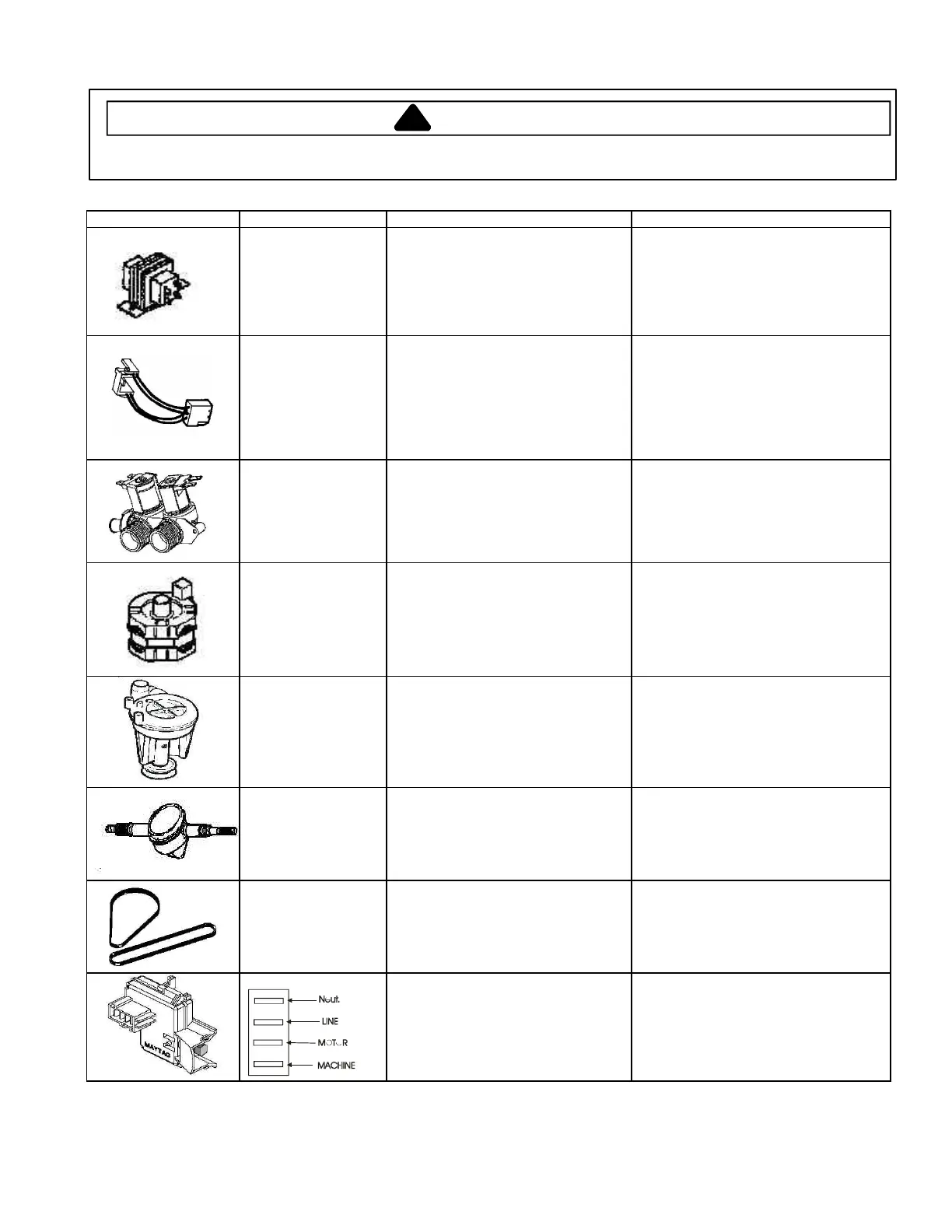

Illustration Component Test Procedure Results

Step-Down

Transformer

Check voltage.

Primary Side:---------------------------------

Secondary Side:

AA6-1 to AA6-2------------------------------

AA6-1to AA6-5 -----------------------------

AA6-2 to AA6-5-----------------------------

AA6-3 to AA6-6------------------------------

120 VAC

2.65 VAC

2.65 VAC

5.3 VAC

22.5 VAC

Coin sensor Check for coin registering.

Coin Sensor Voltage Checks:

1) Blocked- White to Red-----------------

2) Unblocked- White to Red--------------

3) Continuously- Blue to White /Blue---

Display flashes an “*” in “Service Mode”.

23 VDC

0.6 VDC

1.5VDC Note: Replace sensor if voltage

is 23VDC (Open Diode),or 0 VDC

(Shorted Diode),

Water Valve Measure resistance across the

terminals of each coil on the valve.

Measure resistance across thermistor

terminals water temperature (60°F -

140°F degrees).

Approximately 850-950 Ω

Approximately 10K-85KΩ

Motor Type of Motor:

Single speed (Split phase)

See “Motor Testing” section for

correct wiring contact.

Pump Verify drain pump is not clogged or

damaged.

1) Remove clog and verify proper

operation.

2) Replace drain pump if damaged.

Transmission Type of transmission (orbital):

618 r.p.m. Spin

150 o.p.m. Agitate

Check wattage with full tub of water

only (Use Wattage Meter).

See section on “Transmission”

disassembly procedures in base

manual.

380 to 420 watts

Belts Check belt for excessive wear or being

burnt and cracking.

Replace if belt if damaged.

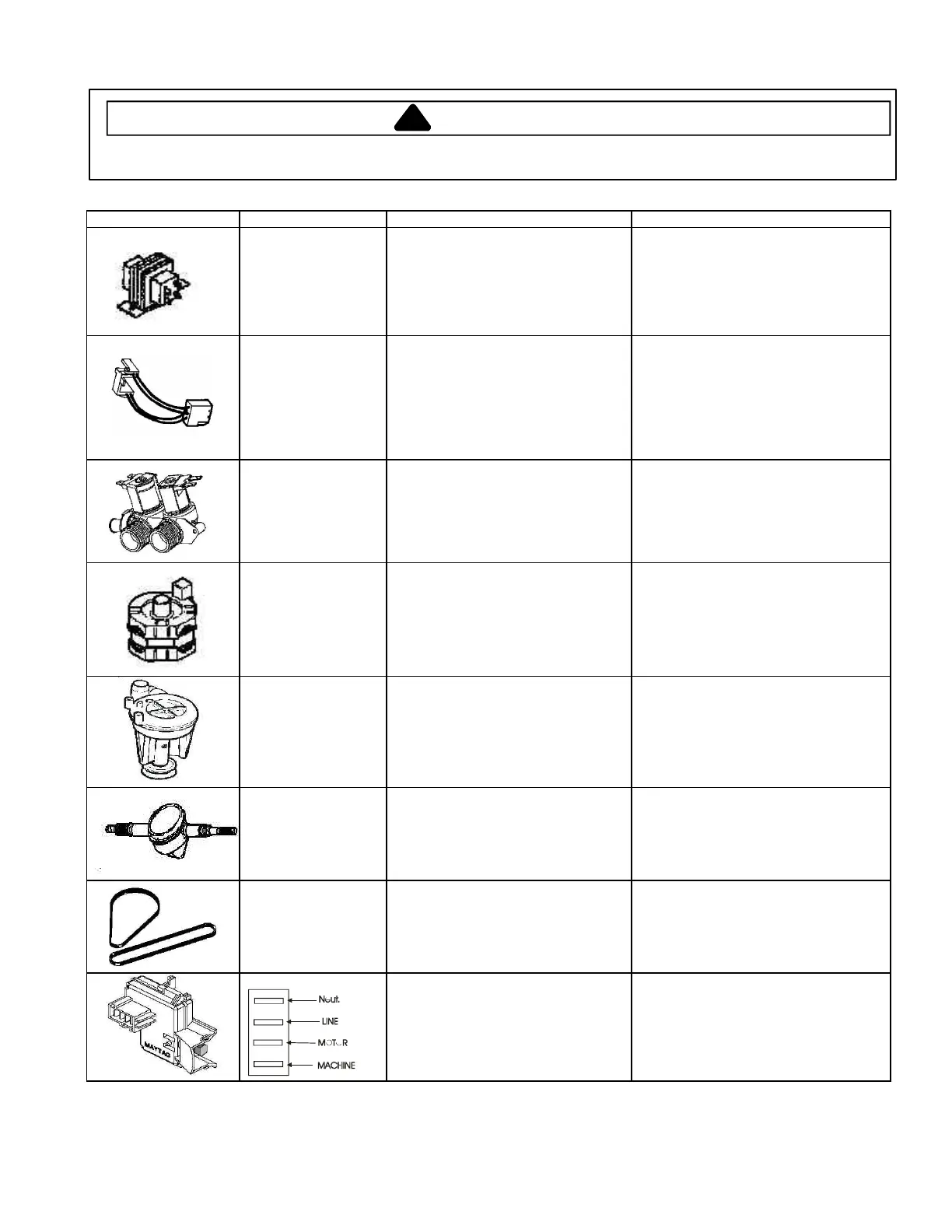

Lid Switch (series 15)

Check for Continuity between the

following terminals:

Line to Machine (Lid Open) --------------

Line to Motor (Lid Closed)----------------

Line to Machine (Lid open or Closed)--

Closed Circuit

Closed Circuit

Closed Circuit, If not replace lid switch.

Loading...

Loading...