- 13 -

3. Slowly loosen clutch cover, counter clockwise and

remove (Warning: Cover under light spring tension)

4. Locate springs under cover and replace with spring

kit (MBW #20859).

5. Reassemble clutch and mount to trowel.

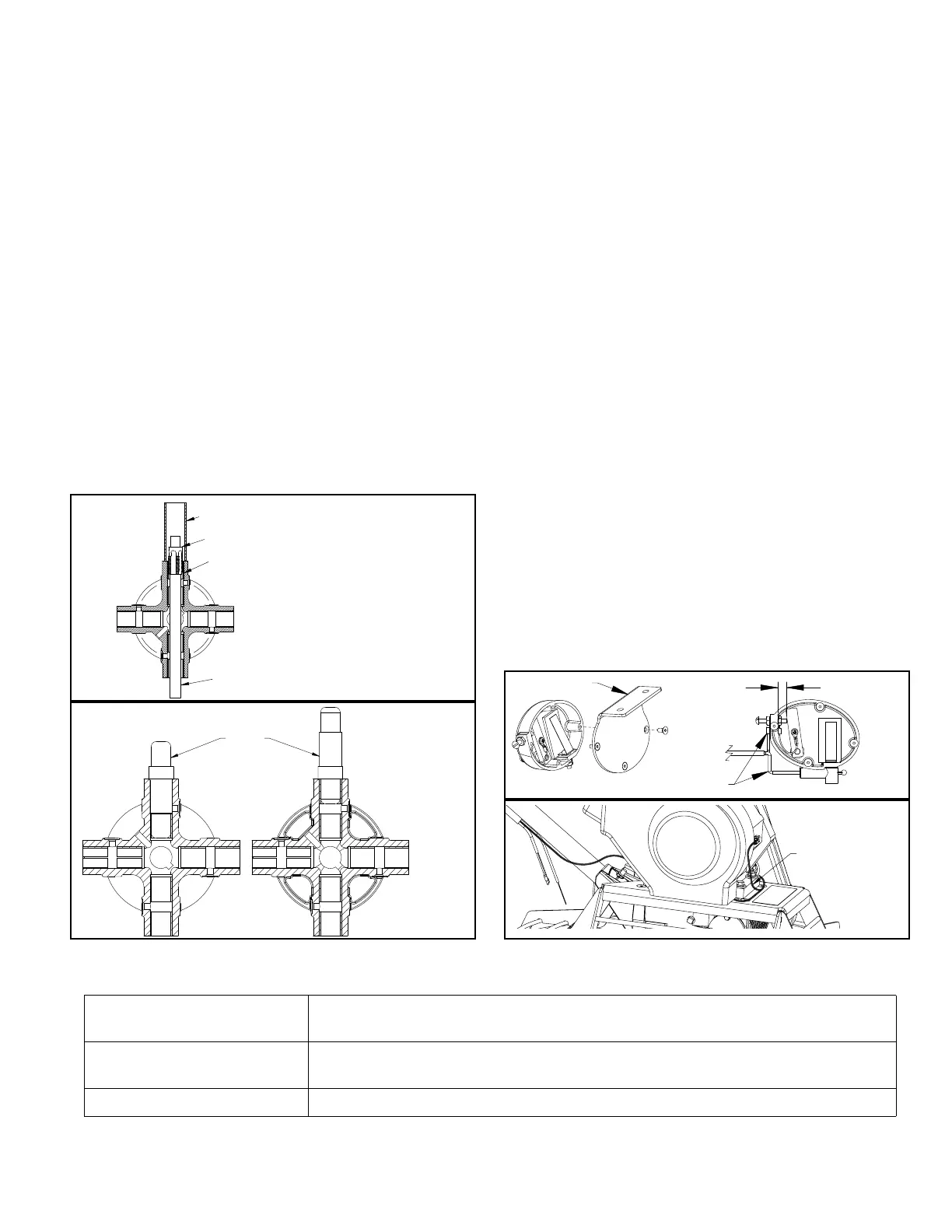

Spider Bushing Removal

Refer to Figure #5

1. Screw 3/4-14 pipe tap half way into outer bushing.

2. Insert push rod into opposite side of spider.

3. Use a tube on upper end to press old bushings out.

4. Repeat with inner bushings.

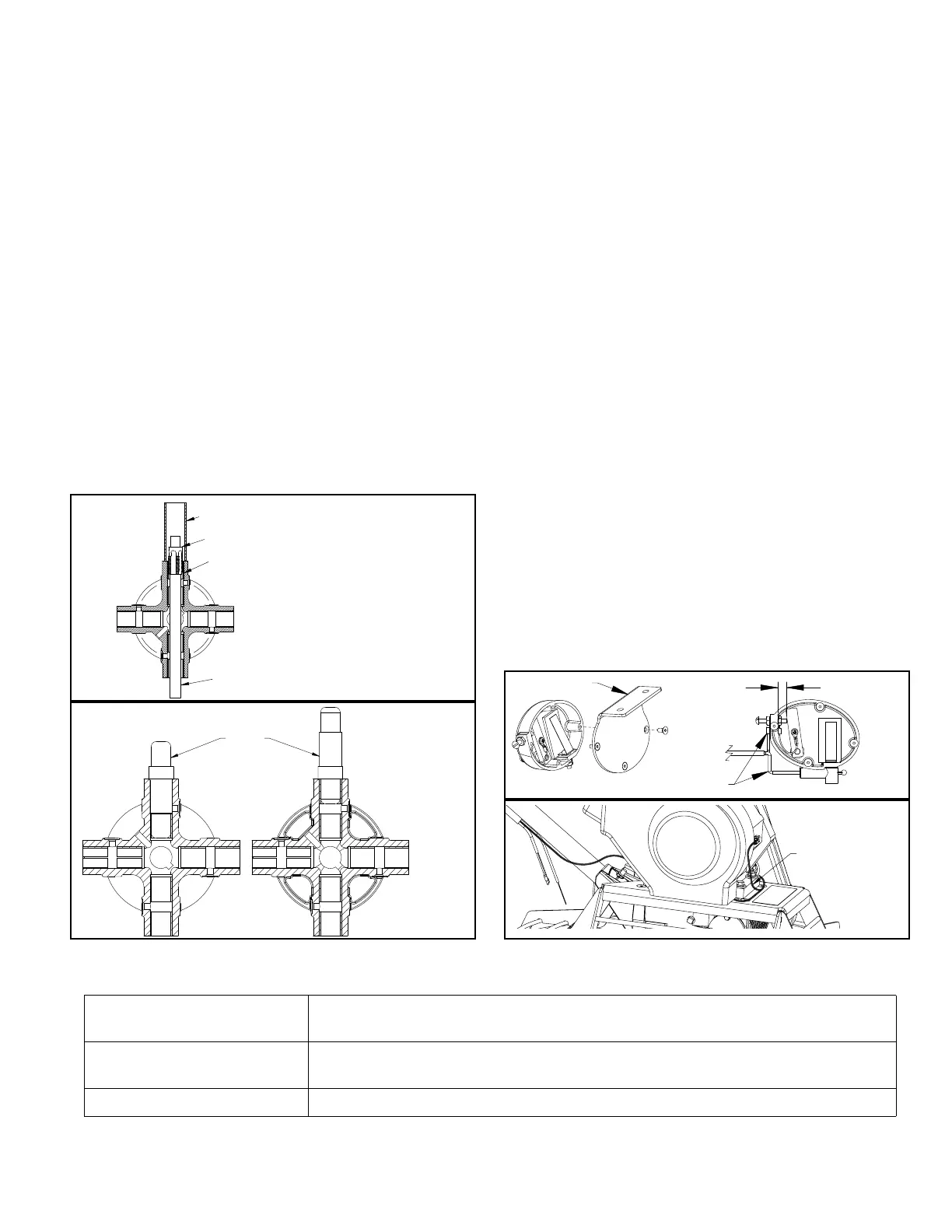

Power Pitch Actuator Replacement

Refer to Power Pitch Actuator & Wiring, page 30.

1. If possible, extend actuator. If unable, elevate trowel

off blades and support from guard ring to relieve

pressure on blade tilt mechanism.

2. Disconnect wiring to actuator.

3. Remove machine screw (13) securing pin (3) at top of

actuator. Use screw to remove pull-pin.

4. Remove machine screw (13) at bottom of actuator

and pull-pin (3).

5. Swivel lower end of actuator away from mount, then

pull down and out from guard (6).

6. Plug in new actuator wiring and extend fully.

7. Insert rod (upper) end of actuator into guard, then

lower end of actuator into socket in the lower actuator

mount(4). Align lower holes and insert pull-pin to

secure.

8. Secure lower pull pin with washer (9) and screw (13).

9. Align holes in upper end of actuator and top mounting

bracket (7). If needed, elevate trowel and pitch

blades manually. Insert pull-pin (3) and secure with

washer (9) and screw (13).

10. Refer to maintenance section of this manual to adjust

actuator for maximum pitch.

Spider Bushing Replacement

Refer to Figure #6 for bushing installation:

1. Install inner bushings into spider with long side of

installation tool #60703 to ensure proper depth.

2. Using the opposite end or short end of installation tool

#06703, install (4) outer bushings into spider.

Parts Replacement Cycles and Tolerances

3,3(7$3

78%(,';/21*

%86+,1*

386+52';

2XWHU

%XVKLQJ

,QQHU

%XVKLQJ

,16,'(&29(5

6+257,1*:,5(6

$77$&+6+257,1*:,5(

5,1*7(50,1$/72

%277205,*+7(1*,1(

6+528'6&5(:

Air Cleaner Element

Replace after 100 hours if the engine is operating under good clean air conditions.

Service and replace more frequently if under more severe conditions.

Bearings

Replace anytime bearing is rough, binding, discolored or removed from housing or

shaft.

Blades Replace when the edges become sharp or uneven. (Finish blades can be reversed)

Loading...

Loading...