- 10 -

SERVICE

Assembly and disassembly should be performed by a

service technician who has been factory trained on MBW

equipment. The unit should be clean and free of debris.

Pressure washing before disassembly is recommended.

• Prior to assembly, wash all parts in a suitable cleaner or

solvent.

• Check moving parts for wear and failure. Refer to the

Replacement section in this manual for tolerance and

replacement cycles.

• All shafts and housings should be oiled prior to pressing

bearings. Also, ensure that the bearings are pressed

square and are seated properly.

• All bearings, seals, o-rings and gaskets should be

replaced when rebuilding gearbox.

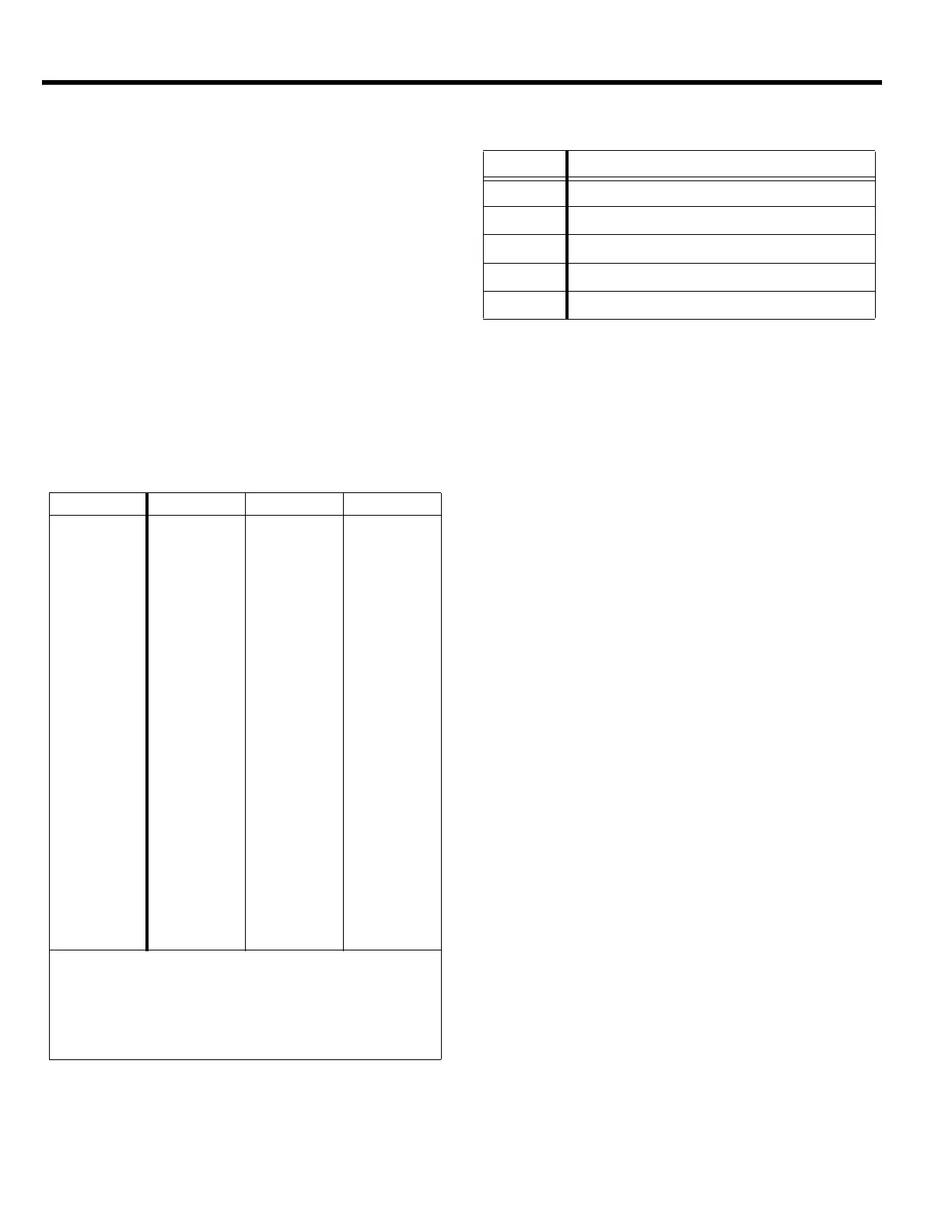

Torque Chart

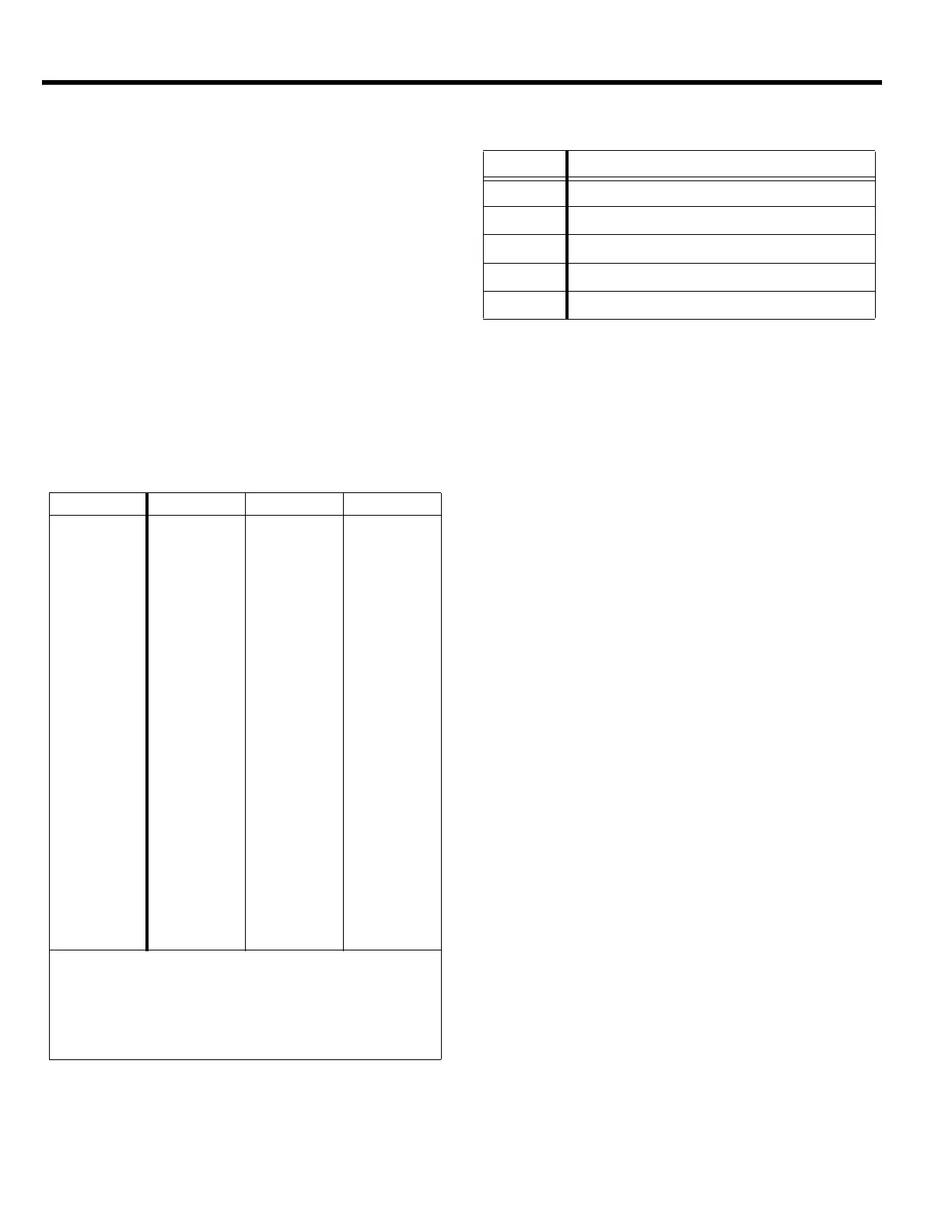

Service Tools

Gearbox Disassembly

Refer to Gearbox Assembly, page 16.

1. Remove handle see handle remove section, belt

guard & drive assembly (page 20), guard ring (page

22).

2. Loosen square head set screw (page 16, #18) until

gearbox can be lifted off the spider assembly.

3. Flip gearbox (8) over and set it on guard ring pads.

4. Remove yoke arm (11) by removing one retaining

rings (7),securing pivot rod (14) and slide rod out of

hole.

5. Remove bolts (30) and flat head screws (31) that hold

cover (9) to the gearbox housing (8).

6. Remove cover and discard shims (13) and o-ring (6).

7. Remove retaining ring (23) and seal (1) from cover,

discard seal.

8. Pull out shaft (18) with bearings (3) and worm gear

(17) and drain oil out of gearbox.

9. Press bearing (#3) and worm gear (17) off long side

of shaft (18).

10. Remove key (19) and retaining ring (2) from shaft.

11. Press remaining bearing (#3) off of shaft.

12. Remove bolts (29) and bearing cap (20). Discard

shim gasket (12) and o-ring (24).

13. Remove worm shaft (15) and bearings (4).

14. Remove retaining cap (10), discard shim gasket (12)

and o-ring (24).

Gearbox Assembly

Refer to Gearbox Assembly, page 16.

1. Lightly oil shaft (18). Install key (19) and retaining ring

(2) onto shaft.

2. With retaining ring end of shaft down, press worm

gear (17) onto shaft. Make sure the longer hub of

worm gear is down. Worm gear should be pressed on

SIZE GRADE 2 GRADE 5 GRADE 8

1/4-20 49 in

•lbs 76 in•lbs 9 ft•lbs

1/4-28 56 in

•lbs 87 in•lbs 10 ft•lbs

5/16-18 8 ft

•lbs 13 ft•lbs 18 ft•lbs

5/16-24 9 ft

•lbs 14 ft•lbs 20 ft•lbs

3/8-16 15 ft

•lbs 23 ft•lbs 33 ft•lbs

3/8-24 17 ft

•lbs 26 ft•lbs 37 ft•lbs

7/16-14 24 ft

•lbs 37 ft•lbs 52 ft•lbs

7/16-20 27 ft

•lbs 41 ft•lbs 58 ft•lbs

1/2-13 37 ft

•lbs 57 ft•lbs 80 ft•lbs

1/2-20 41 ft

•lbs 64 ft•lbs 90 ft•lbs

9/16-12 53 ft

•lbs 82 ft•lbs 115 ft•lbs

5/8-11 73 ft

•lbs 112 ft•lbs 159 ft•lbs

5/8-18 83 ft

•lbs 112 ft•lbs 180 ft•lbs

3/4-16 144 ft

•lbs 200 ft•lbs 315 ft•lbs

1-8 188 ft

•lbs 483 ft•lbs 682 ft•lbs

1-14 210 ft

•lbs 541 ft•lbs 764 ft•lbs

1-1/2-6 652 ft

•lbs 1462 ft•lbs 2371 ft•lbs

M 6 3 ft

•lbs 4 ft•lbs 7 ft•lbs

M 8 6 ft

•lbs 10 ft•lbs 18 ft•lbs

M 10 10 ft

•lbs 20 ft•lbs 30 ft•lbs

CONVERSIONS

in

•lbs x 0.083 = ft•lbs

ft

•lbs x 12 = in•lbs

ft

•lbs x 0.1383 = kg•m

ft

•lbs x 1.3558 = N•m

Part No. Description

07276 Adjustment Tool, Tilt Arm Parallelism

07277 Adjustment Tool, Tilt Arm Height Gage

07279 Installation Tool, Spider Bushing (#06459)

16421 Bearing Spool Tool (Constant Force)

20860 Clutch Drive Tool

Loading...

Loading...