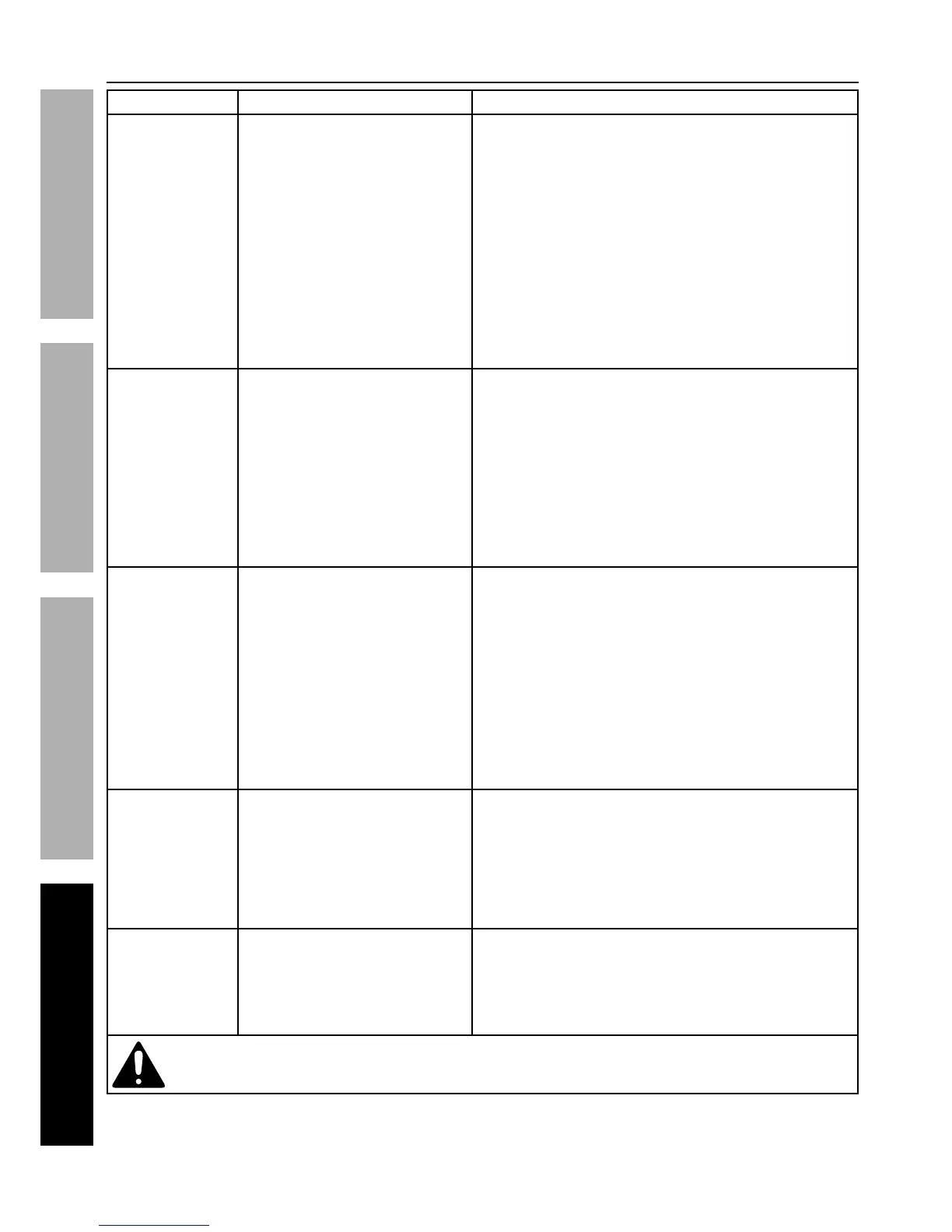

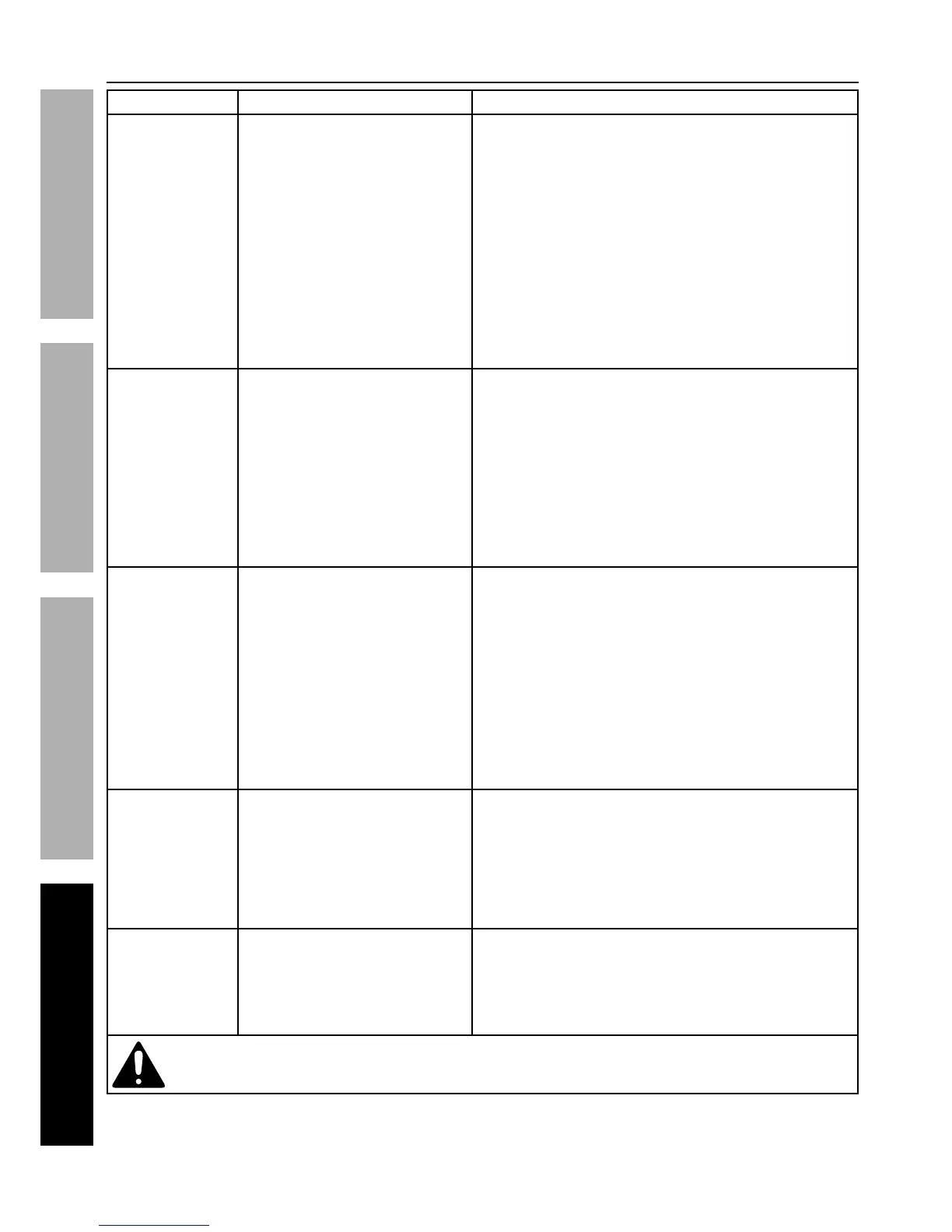

Page 16 @+-*)/93='91<*A,/()'+=(B*4</1(/*91<<*CD###D#!!D$%E%6 Item 64857

FG@;HI JK;LGHMJN OGMNH;NGNP;MNFHGQQGHMJN

H-+,0</(3++)'=8

K-+0</: K+(('0</*P1,(/( Q'X/<V*F+<,)'+=(

Compressor does

not start or restart

1� Tank(s) already pressurized�

2� Power cord not plugged

in properly�

3� Incorrect power supply�

4� No power at outlet�

5� Building power supply circuit

tripped or blown fuse�

6� Cord wire size is too small or

cord is too long to properly

power compressor�

7� Compressor needs service�

1� No problem� Compressor will start when needed�

2� Check that cord is plugged in securely�

3� Check that circuit matches compressor requirements�

4� Reset circuit breaker, or have outlet

serviced by a qualified technician�

5� Reset circuit or replace fuse� Check for low voltage

conditions� It may be necessary to disconnect

other electrical appliances from the circuit or

move the compressor to its own circuit�

6� Use larger diameter or shorter extension cord or

eliminate extension cord� See Recommended Wire

Gauge for Extension Cords in Safety section�

7� Have unit inspected by a qualified technician�

Compressor builds

pressure too slowly

1� Incorrect power supply�

2� Crankcase oil overfilled

or oil too thick�

3� Working environment too cold�

4� Safety valve leaking�

5� Loose fittings�

1� Check that circuit matches compressor requirements�

2� Drain oil and refill to proper level with recommended oil�

3� Move compressor to a warmer location�

Check that recommended oil is in crankcase�

4� Listen for air leaking from valve�

If leaking, replace with identical valve with same rating�

UJ*NJH*F;GQ*JL*HGOK;L*RMH^*FG@;HI*&GQ&;6

5� Reduce air pressure, then check all fittings

with a soap solution for air leaks and tighten

as needed� Do not overtighten�

Compressor not

building enough

air pressure

1� Air filter needs cleaning�

2� Check Valve needs service�

3� Compressor not large enough for

job�

4� Loose fittings�

5� Hose or hose connections

too narrow�

6� Crankcase oil too thick�

7� High altitude reducing air output�

1� Check air filter and clean as needed�

2� Have technician clean or replace, as needed�

3� Check if accessory CFM is met by Compressor�

If Compressor cannot supply enough

air flow (CFM), use a larger Compressor�

4� Reduce air pressure, then check all fittings

with a soap solution for air leaks and tighten

as needed� Do not overtighten�

5� Replace with wider hose and/or hose connections�

6� Drain oil and refill to proper level with recommended oil�

7� Higher altitudes require compressors with greater output�

Overheating 1� Air filter needs cleaning�

2� Crankcase oil too thin

or incorrect type�

3� Crankcase oil level too low�

4� Unusually dusty environment�

5� Extension cord used�

6� Unit not on level surface�

1� Check air filter and clean as needed�

2� Drain oil and refill to proper level with recommended oil�

3� Add oil to proper level, check for leaks�

4� Clean filter more often or move unit to cleaner environment�

5� Eliminate extension cord�

6� Reposition unit on a level surface�

Compressor

starts and stops

excessively

1� Loose fittings�

2� Compressor not large

enough for job�

1� Reduce air pressure, then check all fittings

with a soap solution for air leaks and tighten

as needed� Do not overtighten�

2� Check if accessory CFM is met by Compressor�

If Compressor cannot supply enough

air flow (CFM), use a larger Compressor�

* @+<<+.*1<<*(17/)V*4-/91,)'+=(*.3/=/W/-*>'18=+('=8*+-*(/-W'9'=8*)3/*9+:4-/((+-6***

U'(9+==/9)*4+./-*(,44<V*0/7+-/*(/-W'9/6

Loading...

Loading...