12

AGR 070A through 100A Product Manual AGR-3

Selection example

Given:

64 tons required capacity

95°F ambient temperature

Cool 154 gpm from 54

°

F to 44°F

0.0001 evaporator fouling factor

2,000 foot altitude

Add 3% to the required capacity for approximate derate: 64 x 1.03 = 66 tons. From Performance Table

9, an AGR-070AM at the given conditions will produce 67.5 tons with a compressor kW input of 77.1

and a unit EER of 9.6.

1.

Determine derate factors :

Altitude correction from Table 3: 0.986 Capacity, 1.009 Power

2.

Piping correction:

Assume 2 1/8" suction line based on connection size in Table 6

(3) 90

°

Standard ells (Table 4) 3 x 5 ft =15 ft

Plus actual linear feet 70 ft

Total Equivalent Feet 85 ft

Check Table 7 for size and find that 2 1/8” is acceptable size for oil carry. If the selected riser size

is too large, double risers would be required. See Refrigerant Piping section for important

information, including double riser layouts.

The capacity correction factor from Table 8 is 0.984.

3.

The corrected capacity of the AGR is: 67.5 tons x 0.986{altitude} x 0.984{piping} = 65.5 tons

This satisfies the 64 ton requirement.

4.

Correct the compressor power required: 77.1 kW x 1.009{altitude} = 77.8 kW.

5.

Calculate the unit power input from corrected EER:

W = BTU / EER W =65.5 tons x 12,000 / (9.6 EER / 1.009) = 81.1 kW

6.

Determine the evaporator pressure drop. Enter the pressure drop curves (Figure 9) at 154 gpm and

read up to AGR 070AM, read over to pressure drop of 15 ft.

Selection example using ethylene glycol

Given: 64 tons required capacity

95

°

F ambient temperature

54

°

F to 44

°

F chilled fluid

0.0001 fouling factor

Protect from freezing down to 0°F

1.

From Table 1, select an ethylene glycol concentration of 40% to protect against freezing at 0°F.

2.

At 40% ethylene glycol, the adjustment factors are: Capacity =0.961, kW = 0.976,

Flow = 1.121, pressure drop = 1.263

3.

Select the AGR 070AM and correct with 40% ethylene glycol factors and piping correction factor.

4.

Correct capacity = 0.961 X 67.5 tons = 64.6 tons

5.

Correct compressor kW = 0.976 X 77.1 = 75.2 kW

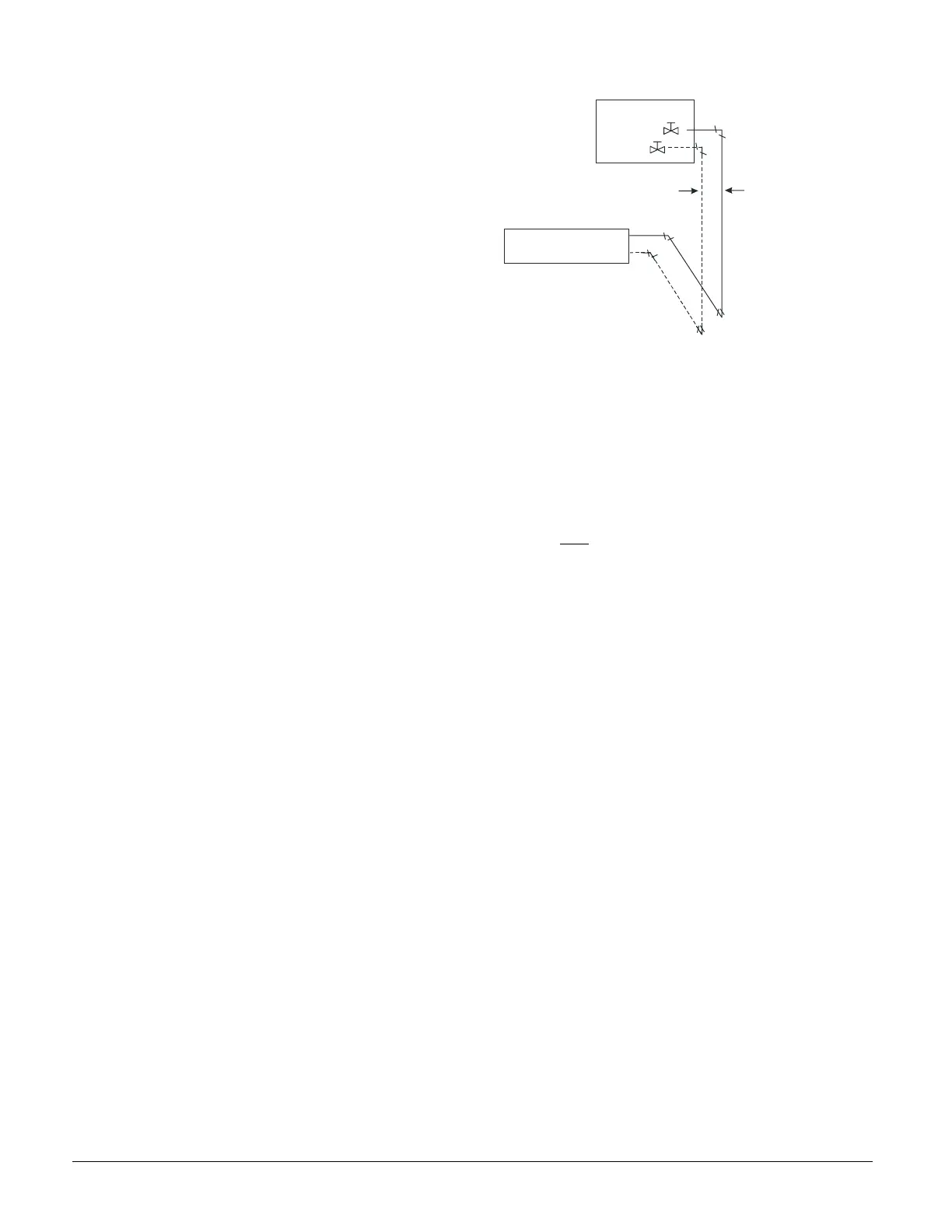

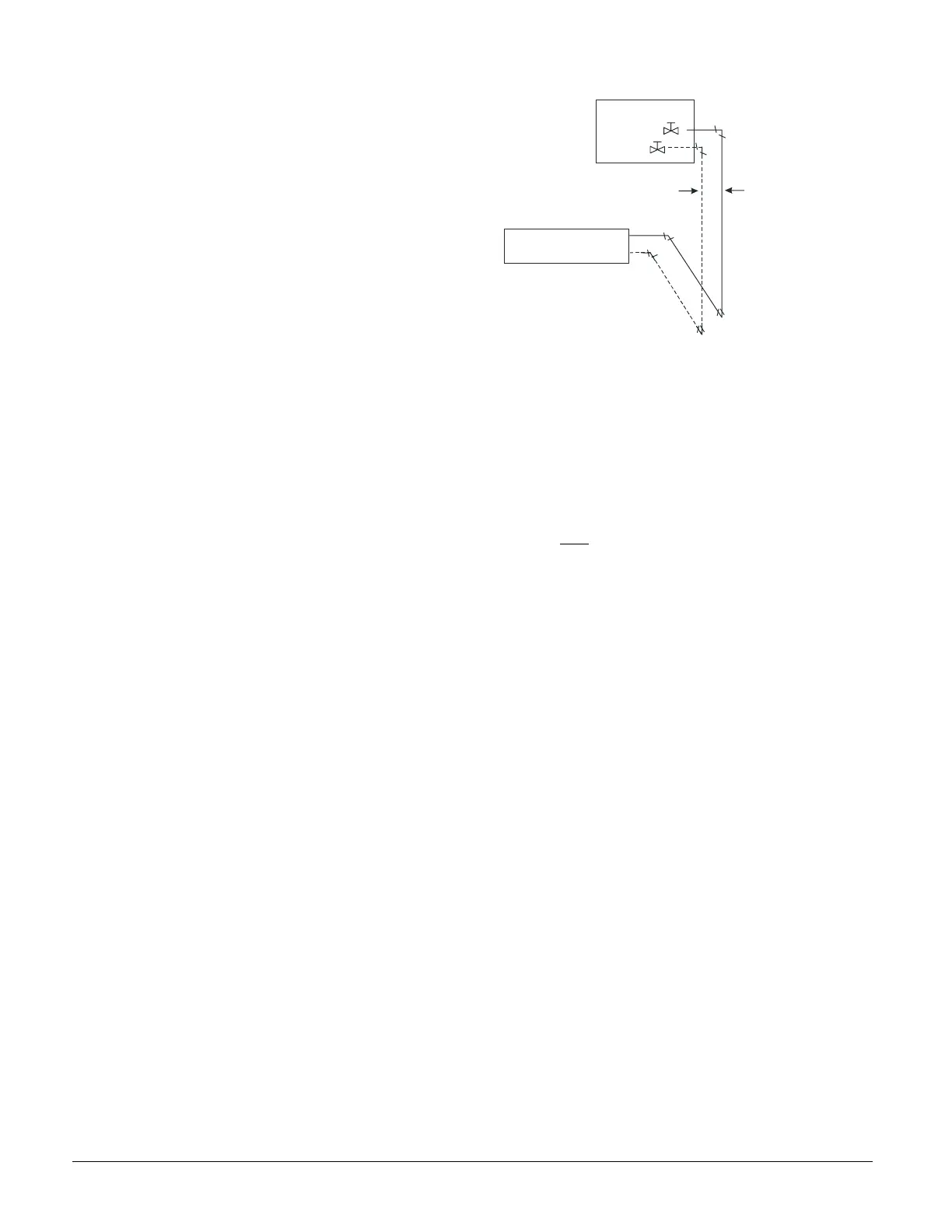

Figure 5, Sample Piping Layout

GR-AM

Remote Eva

orator

10 ft.

30 ft.

20 ft.

10 ft.

Li

uid

Line

Suction

Line

Loading...

Loading...