4

AGR 070A through 100A Product Manual AGR-3

Design Advantages

Construction

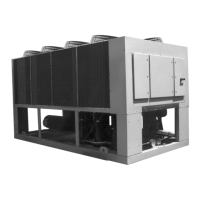

Factory assembled and mounted on heavy-gauge powder coat painted, galvanized steel channel base.

This base distributes the unit weight for roof loading. Flexible installation is possible by virtue of the

unit’s small footprint and low sound level.

Compressors

The AGR product line uses Copeland DISCUS

valve semi-hermetic compressors. These rugged

compressors are designed for R-22 and the high loading associated with air-cooled applications. They

operate under lighter loading with R-134a.

Semi-hermetic, 1750 rpm induction type motors are used. The motors are refrigerant-gas cooled.

Solid-state modules in the motor terminal box respond to temperature sensors imbedded in all three

motor windings, providing inherent thermal overload protection for all run and start conditions.

The compressor housing is constructed from closed grained, high nickel content, alloy cast-iron with no

bolted joint between the motor and compressor. The housing includes a cast-iron cylinder head and

stator cover, and a crankcase oil sightglass. A suction strainer built into the compressor in the gas

stream between the suction service valve and the motor, filters out foreign and abrasive particles. An

internal relief valve relieves discharge pressure to the suction side for protection at high compression

ratios as required by ANSI/ASHRAE 15 Safety Code.

Main bearings are solid cast bronze insert type with oversized bearing areas that result in ultra-low

bearing loading.

The crankshaft is die-forged, high strength iron alloy with integral counterweights, statically and

dynamically balanced for smooth operation.

Connecting rods are lightweight aluminum with integral bearing surfaces on the crankshaft and piston

ends. Pistons are close grain cast iron with oil and compression rings. Piston pins are full floating type

for long life.

Compressors have a force-feed lubrication system with positive oil displacement, a reversible oil pump,

and an operating oil charge. The pump feeds oil through rifle drilled passages in the crankshaft to all

bearing surfaces. Magnetic plugs trap metal particles that enter the crankcase. The oil supply is filtered

through a large area oil strainer. A crankcase heater minimizes oil dilution by refrigerant at compressor

startup.

Condenser Coils

Condenser coils have internally enhanced seamless copper tubes arranged in a staggered row pattern.

The coils are mechanically expanded into McQuay lanced and rippled aluminum fins with full fin

collars. An integral subcooler circuit provides subcooling to greatly reduce the possibility of liquid line

flashing. The exterior condenser coils are fitted with a vinyl-coated wire mesh protective guard.

Condenser Fans and Motors

Multiple direct drive dynamically balanced propeller fans operate in formed venturi openings at low tip

speeds for maximum efficiency and minimum noise and vibration. A heavy-gauge vinyl-coated fan

guard protects each fan.

Each condenser fan motor is heavy-duty, 3-phase with permanently lubricated ball bearings and

inherent overload protection. SpeedTrol option includes a single-phase motor with fan speed control on

the lead fan per circuit. Fan motors on the AGR 070-100A are totally-enclosed-air-over (TEAO)

construction providing optimum environmental protection.

Copeland's Compliant Scroll® is a registered trademark of the Copeland Corporation, Sydney, Ohio.

Loading...

Loading...