Product Manual AGR-3 AGR 070A through 100A

39

electrical conduit to isolate sound through electrical conduit. Spring isolators are effective in reducing

the low amplitude sound generated by reciprocating compressors and for unit isolation in sound

sensitive areas.

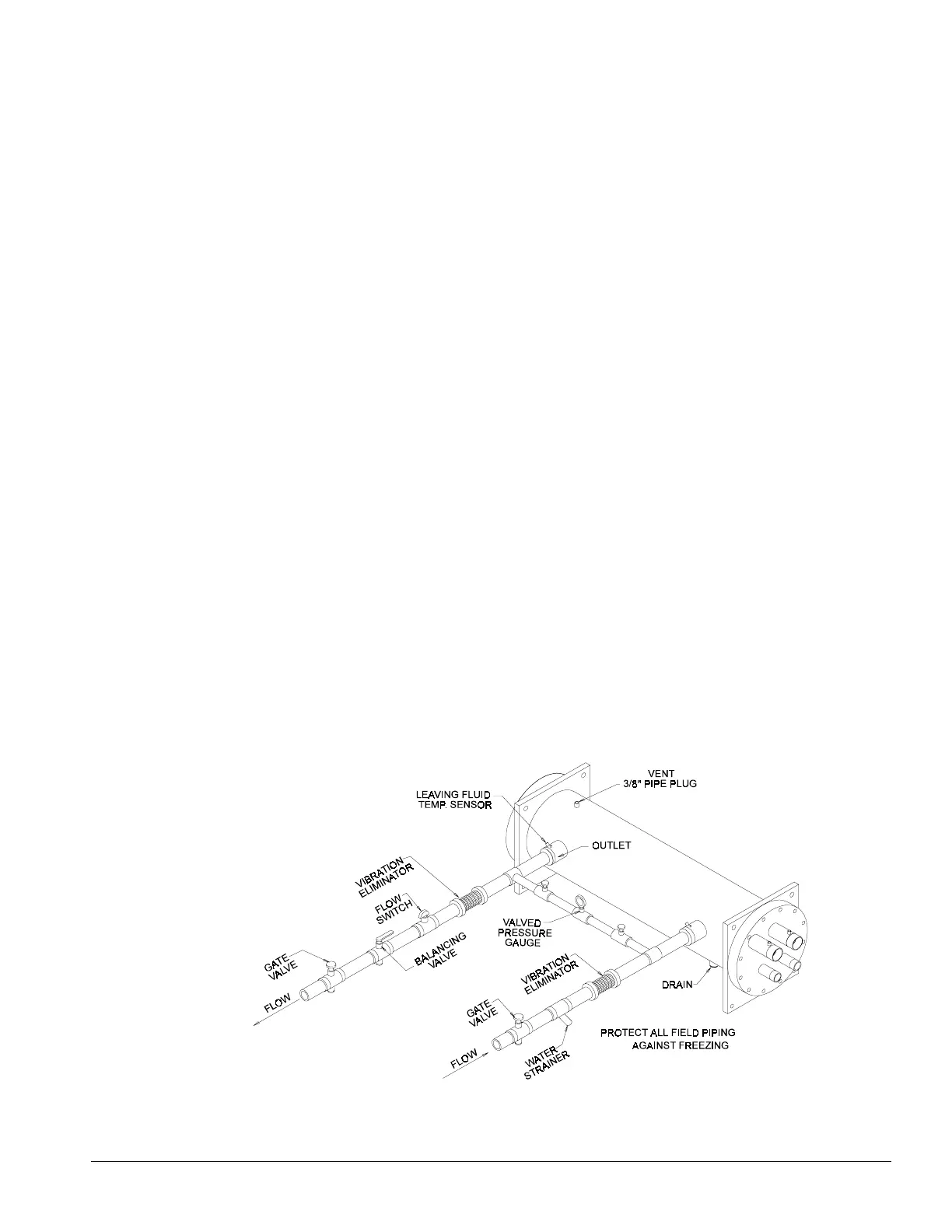

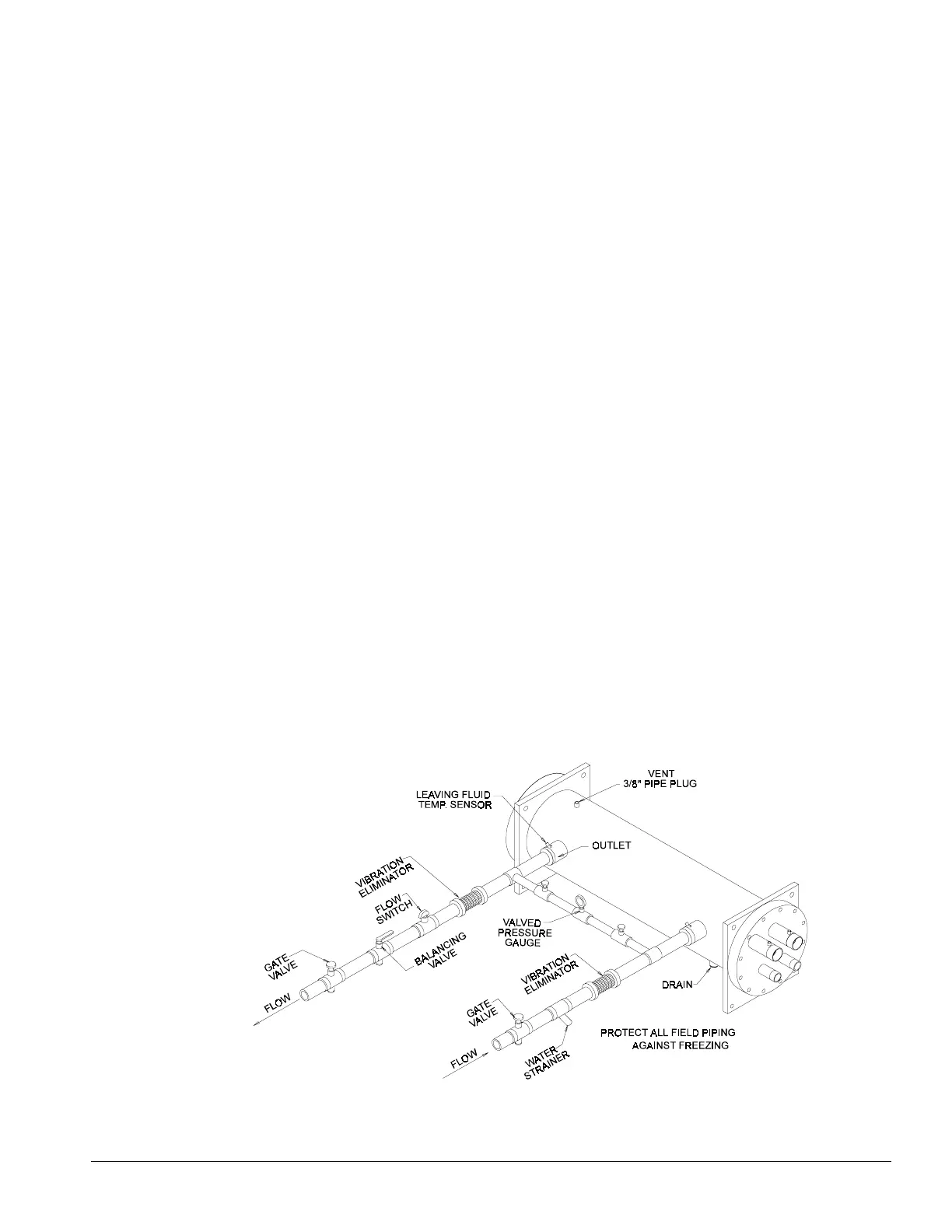

Typical Chilled Water Piping

Flush the system water piping thoroughly before making connections to the unit evaporator. Install a

strainer of 40 mesh in the return water line before the inlet to the chiller. Design the water piping so the

chilled water circulating pump discharges into the evaporator inlet.

Connect the return water line to the evaporator inlet connection. Connect the supply water line to the

evaporator outlet connection.

Install and calibrate a flow switch in the horizontal piping of the supply (evaporator outlet) water line.

Provide drain connections at low points in the system to permit complete drainage of the system. Locate

air vents at the high points in the system to purge air out of the system. A vent connection on top of the

evaporator vessel allows air to be purged out of the evaporator. Purge air from the water system before

unit start-up to ensure adequate flow through the evaporator.

Install pressure gauges in the inlet and outlet water lines to the evaporator. Measure pressure drop

through the evaporator and compare to flow as shown in Figure 9. Vibration eliminators are

recommended in both the supply and return water lines.

Insulate chilled water piping to reduce heat loss and prevent condensation. Chillers not running in the

winter should have their water systems thoroughly drained to protect against freezing. If the chiller

operates year round, or if the system is not drained for the winter, protect the chilled water piping

exposed to outdoor temperature against freezing. Wrap the lines with a heater cable and add proper

amount of glycol to the system to further protect the system.

The total water volume in the system should be sufficient to prevent “on-off” cycling. Turnover rate

should not be less than 8 minutes for normal variable loads. Turnover rate for process cooling or a

constant load, should not be less than 6 minutes.

Chilled Water Piping

The thermostat sensor is factory mounted in the leaving water thermowell on AS units. If an optional

high return water sensor is provided, install sensor bulb in a field supplied tee or strap to the outside of

the water line.

Figure 18, Typical Chilled Water Piping

Loading...

Loading...