-88-

Design & installation Guide For McQuay MDS Multi System

4.3.7 Process sequence of air leakage test

■ Main points of testing

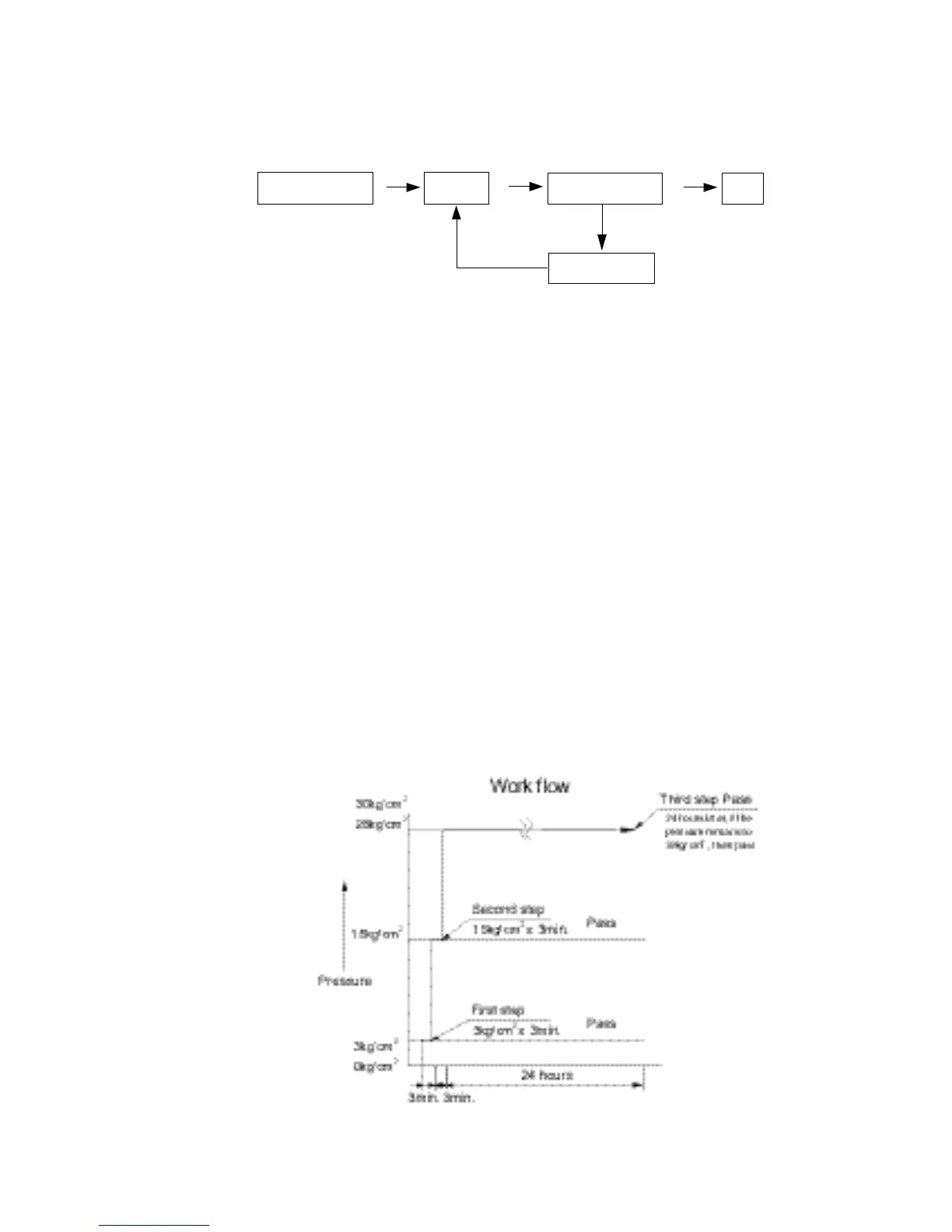

Please test as follows:

● The Pressure charging must be tested both in liquid pipe and gas pipe.

◆ First step, keep 3.0kg/cm2 pressure gas for more than 3 minutes---may be can find big gap;

◆ Second step, keep 15.0kg/cm2 pressure gas for more than 3 minutes---may be can

find big gap;

◆ Third step, keep 28.0kg/cm2 pressure gas for more than 24 hours.

Notes:

Keep the 28.0kg/cm2 pressure gas must more than 24 hours.

The pressure can not be more than 28.0kg/cm2!

● Check the pressure decrease or not

◆ If the pressure remain the same, then it is OK;

◆ If the pressure decrease, then we should find out the leak gap.

◆ If the ambient temperature when pressure is charged is different from the temperature when

observing, the pressure need to be modified as follows:

Modified value = (temperature when pressure is charged- temperature when observing)x 0.1;

e.g.: when pressure is charged to 28.0kg/cm2 and the ambient temperature is 25℃; after

24 hours, the pressure is 27.5kg/cm2 and the temperature is 20℃, then you can

have a conclusion that it is OK.

No

yes

Pressure

charging

Pass

check and

maintain it

refrigerant piping

assembly finished

is the pressure

released?

Loading...

Loading...