-89-

Design & installation Guide For McQuay MDS Multi System

4.3.8 Air leak gap checking

■ Test 1 (when the pressure reduces)

● Hearing — use your ear to find it out.

● Touching — use your hand to find it out.

● Soap water — use soap water to find it out.

■ Test 2 (when step 1 can not find out , then the following should be adopted)

● Reduce nitrogen pressure to 3.0kg/cm2;

● Charge the nitrogen with R22 to 5.0kg/cm2;

● Use haloid lamp, alkyl detector or electric controller to check;

● If still can not find the air leak gap, then the pressure should be charged to 28.0kg/cm2 and

check it again;

(The pressure can not be more than 28.0kg/cm2).

Notes:

If the pipe is too long, it should be divided to sections to test as follows:

● Indoor side

● Indoor side + vertical pipes

● Indoor side + vertical pipes + outdoor piping assembly

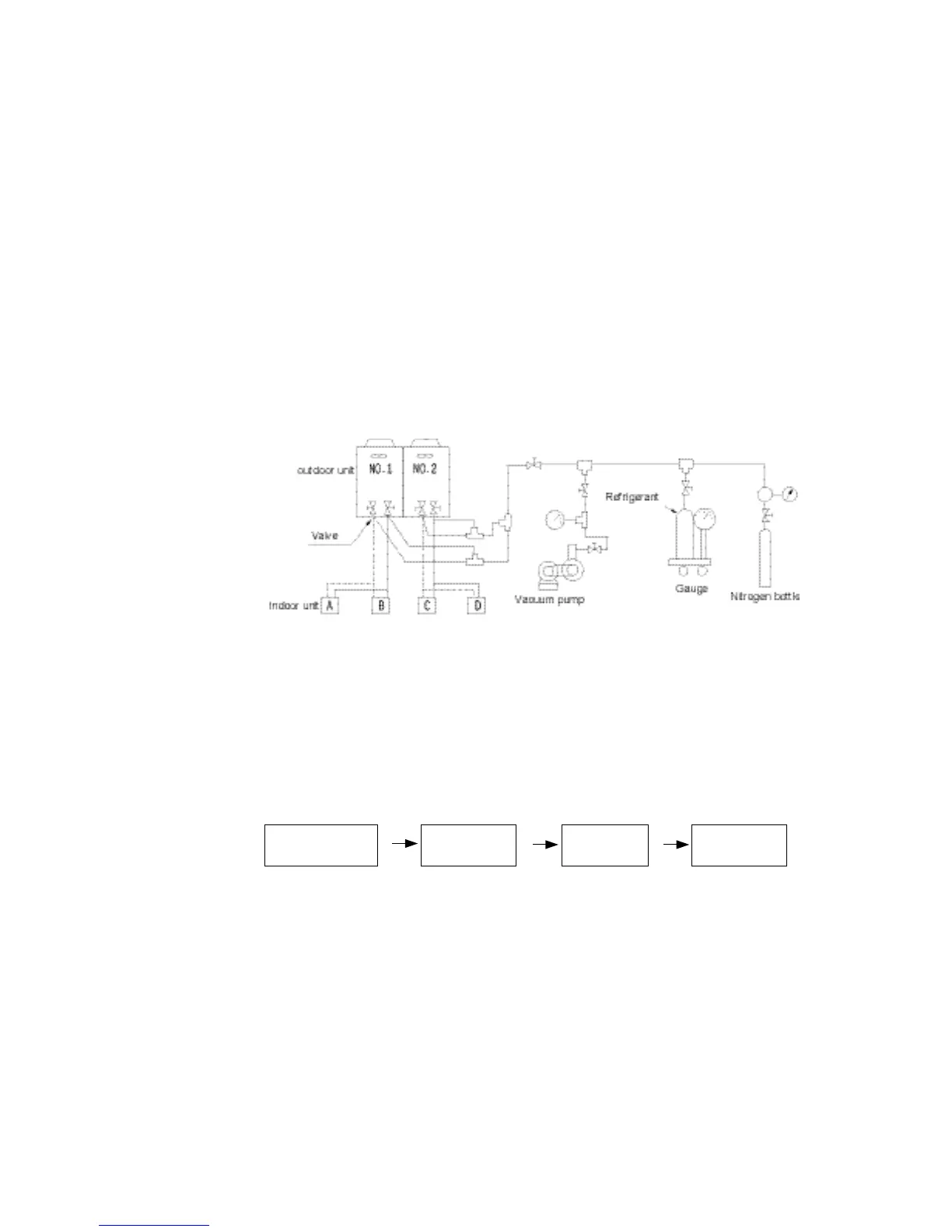

4.3.9 copper pipe insulation

■ Material

All the insulation material should be strong enough to insulate the pipe.

For example, polyethylene is a good insulation material.

■ key points

Some areas such as welding area, enlarged port area and flange area can be insulated only

after the air leak test. Pay attention to the unit model and the running condition, for some gas

pipe and liquid pipe are all needed to be insulated.

pipe insulation

Refrigerant piping

assembly

pipe insulation

air leak test

Loading...

Loading...