-90-

Design & installation Guide For McQuay MDS Multi System

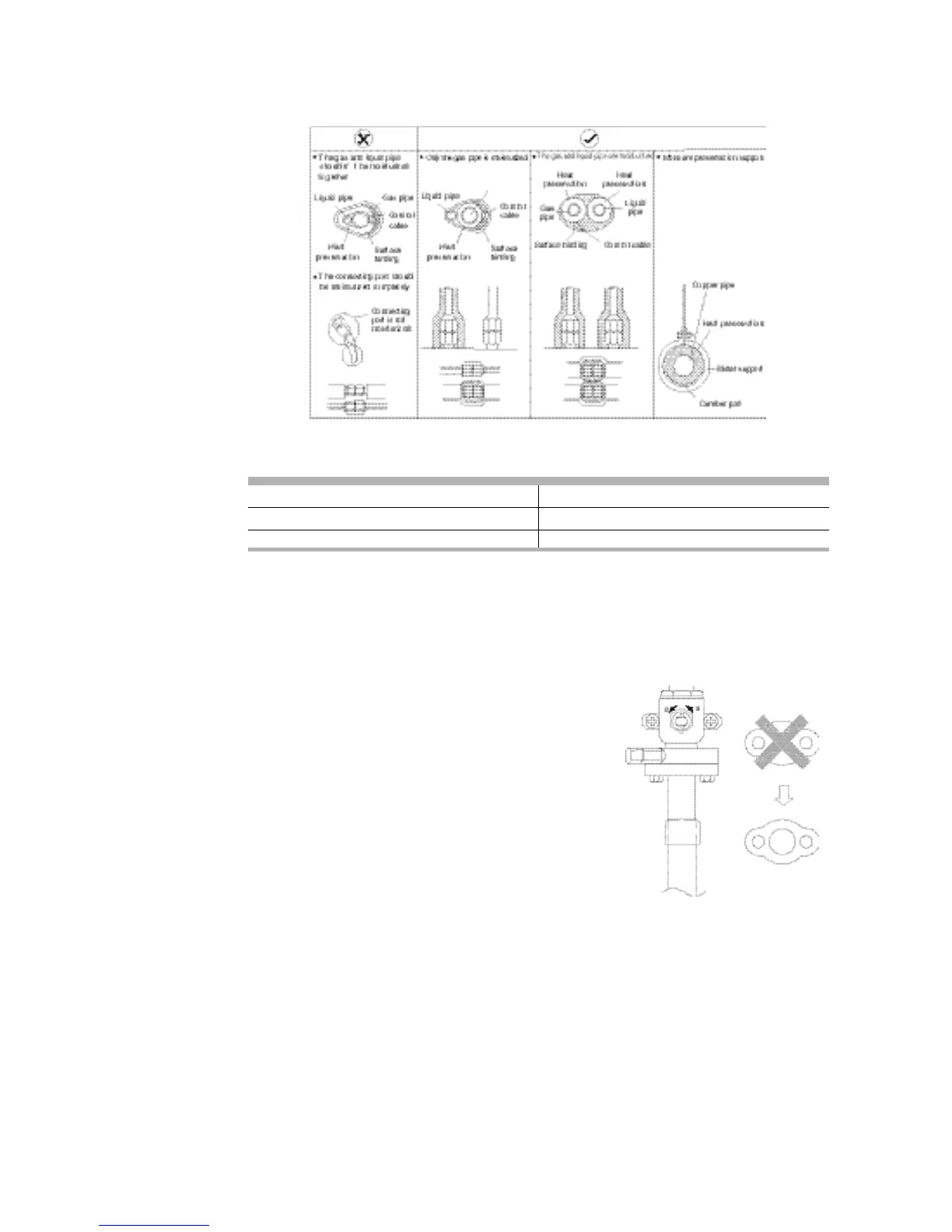

Pipe size Thickness of the insulation material

6.4mm~25.4mm 10mm or more

28.6mm~38.1mm 15mm or more

● In case the environment is hot and damp, increase the recommended thickness (1 inch for the

main pipe, and half inch for the refnet joint) in the table above.

● For the cooling only unit, if it is predicted that the system might run in the ambient temperature

of less than 10℃degrees Celsius, the liquid pipe should also be insulated.

■ Key points

The thickness of insulation materials depends on the pipe size.

4.3.10 Globe valve operation

■ Globe valve operation procedures

Make sure the pipes are connected and the valves are

operation correctly. Please install and operate the valves

as follows:

● Gas side globe valve operation

1) Remove the connection pipe with flange: Remove

the connection pipe with flange from the gas side

globe valve and braze it to the outside of the unit.

2) Stick the sealing material: When removing the con-

nection pipe and flange, remove the sealing material on

the globe valve label and stick it on the flange of the

globe valve to prevent dusts into the globe valve.

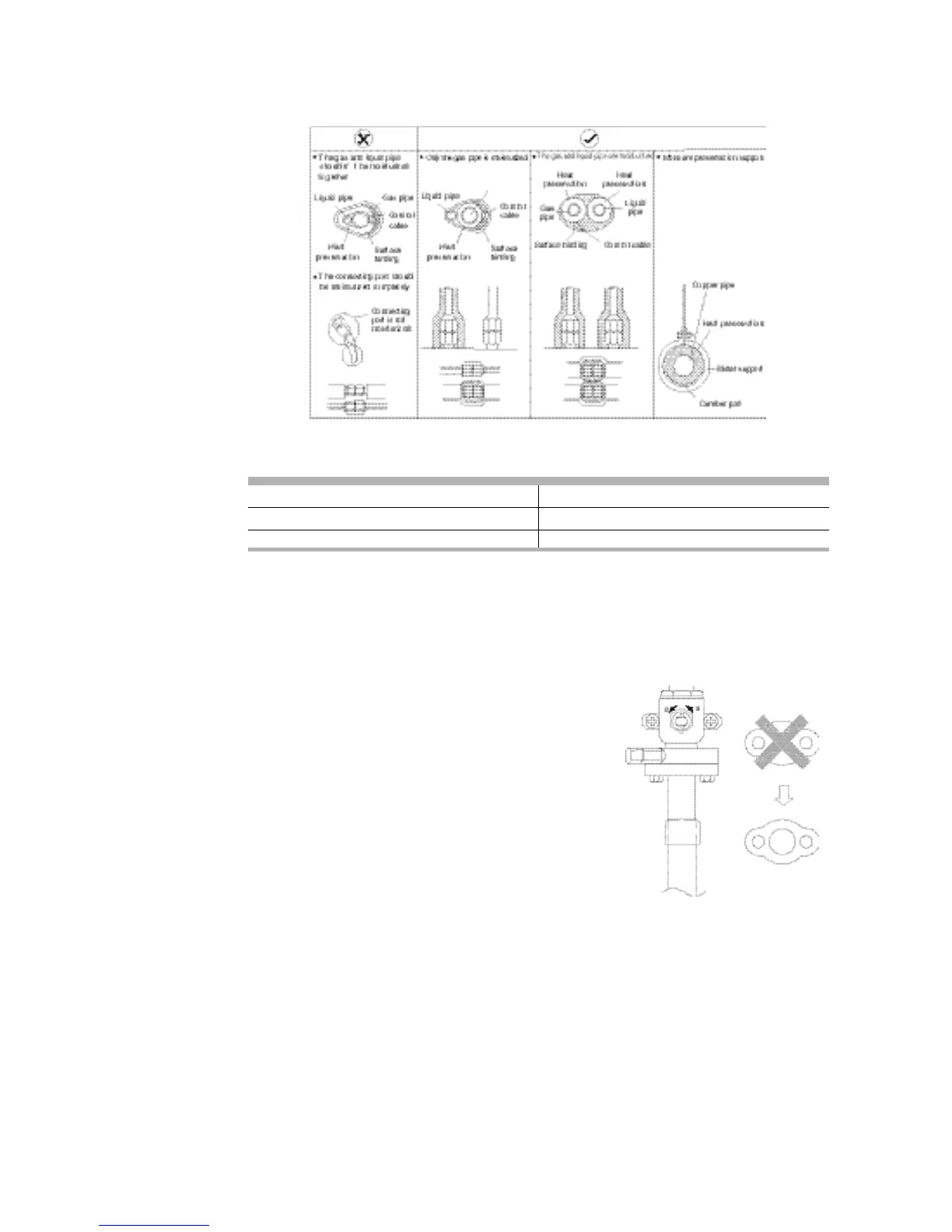

3) Replace the hollow gasket: Before delivery, seal

the refrigerant circulation loop with a round solid seal-

ing plate to avoid gas leakage between flanges. In such status, the system cannot run. So,

please replace with the hollow gasket on the globe valve. Before installing the hollow gasket,

clean the flange surface and the sealing plate.

4) Fix the connection pipe welded with gas pipe, hollow gasket and gas globe valve with screws.

● Connection of the liquid side stop valve: Expand the flare fitting of the copper pipe. Then,

connect it with the threaded stop valve.

● After pumping vacuum and fill refrigerant, make sure the valve is fully open. If the system runs

when the valve is closed, the unit pressure will be abnormal, damaging the compressor and

four-way valve.

● Calculate the refrigerant amount to be added with the formula (refer to Section 9.3), and fill

the amount through the access opening when the pipe connection work is complete.

● After the work is finished, firmly fix the access opening and cap to avoid gas leakage.

Loading...

Loading...