CAPACITY CONTROL SYSTEM

The compressor capacity is controlled by the movement of

the inlet vanes, opening or closing to permit the correct quan-

tity of refrigerant to enter the wheel or impeller. The vane

movement occurs in response to oil flow from the SA or SB

solenoid valve which, in turn, respond to a control module

signal. This oil flow activates a piston to rotate the vanes.

VANE OPERATION

The hydraulic system for the vane control operation consists

of a

4-way normally open solenoid valve. Oil under pressure

is directed by the 4-way valve to either or both sides of the

piston depending on whether the control signal is to load,

unload or hold.

To open the vanes (or load the compressor) solenoid “SA”

is de-energized and solenoid “SB” is energized, allowing oil

flow from port SA to one side of the piston then drain through

port SB.

To close the vanes (unload compressor) valve SB is

de-

energized and valve SA is energized to move the piston and

vanes to unload position.

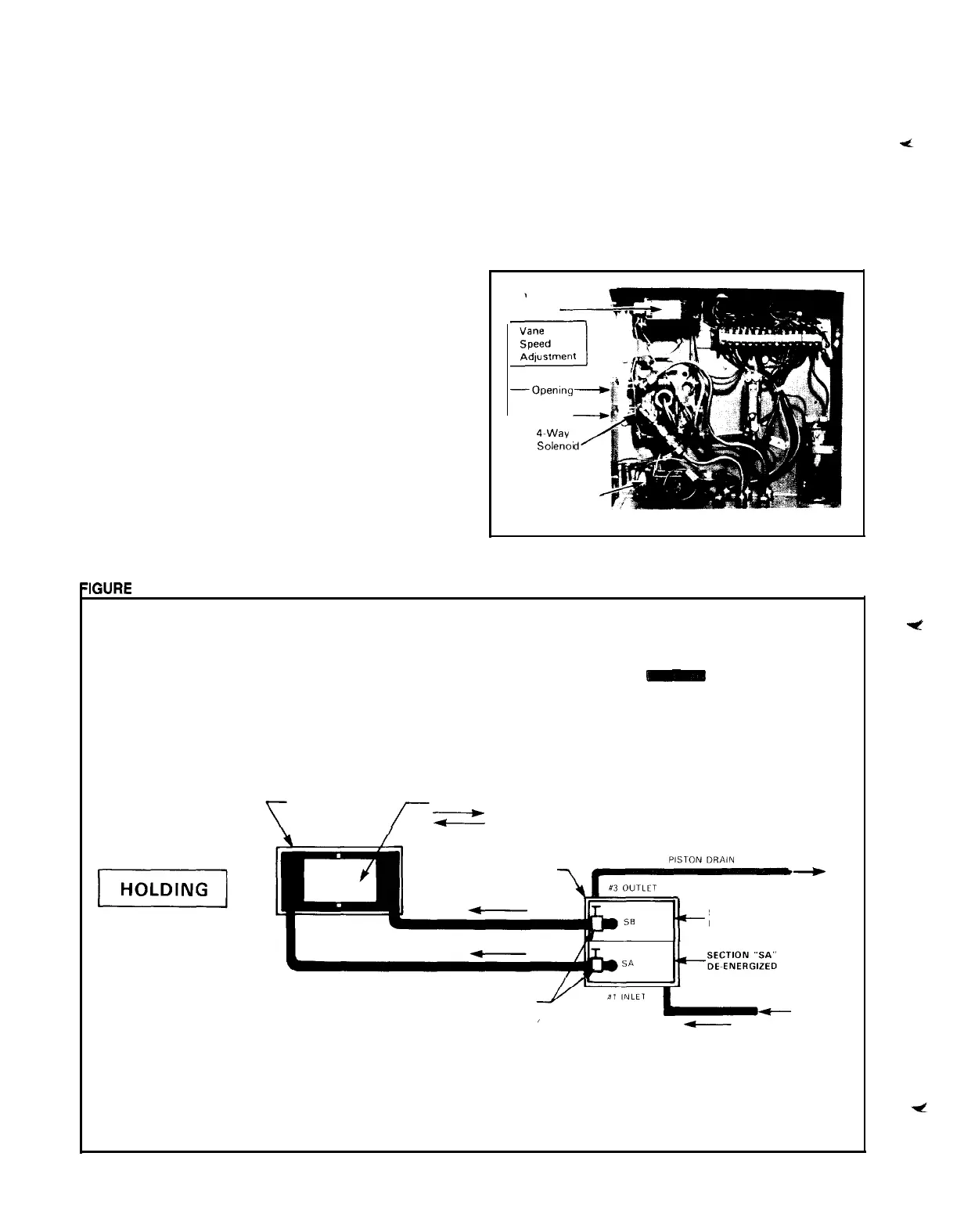

When both solenoid valves SA and SB are de-energized,

full oil pressure is directed to both sides of the piston through

ports SA and SB, thus the vanes are held in that position.

Refer to Figure 7 for solenoid action. Note that both solenoids

cannot be energized simultaneously.

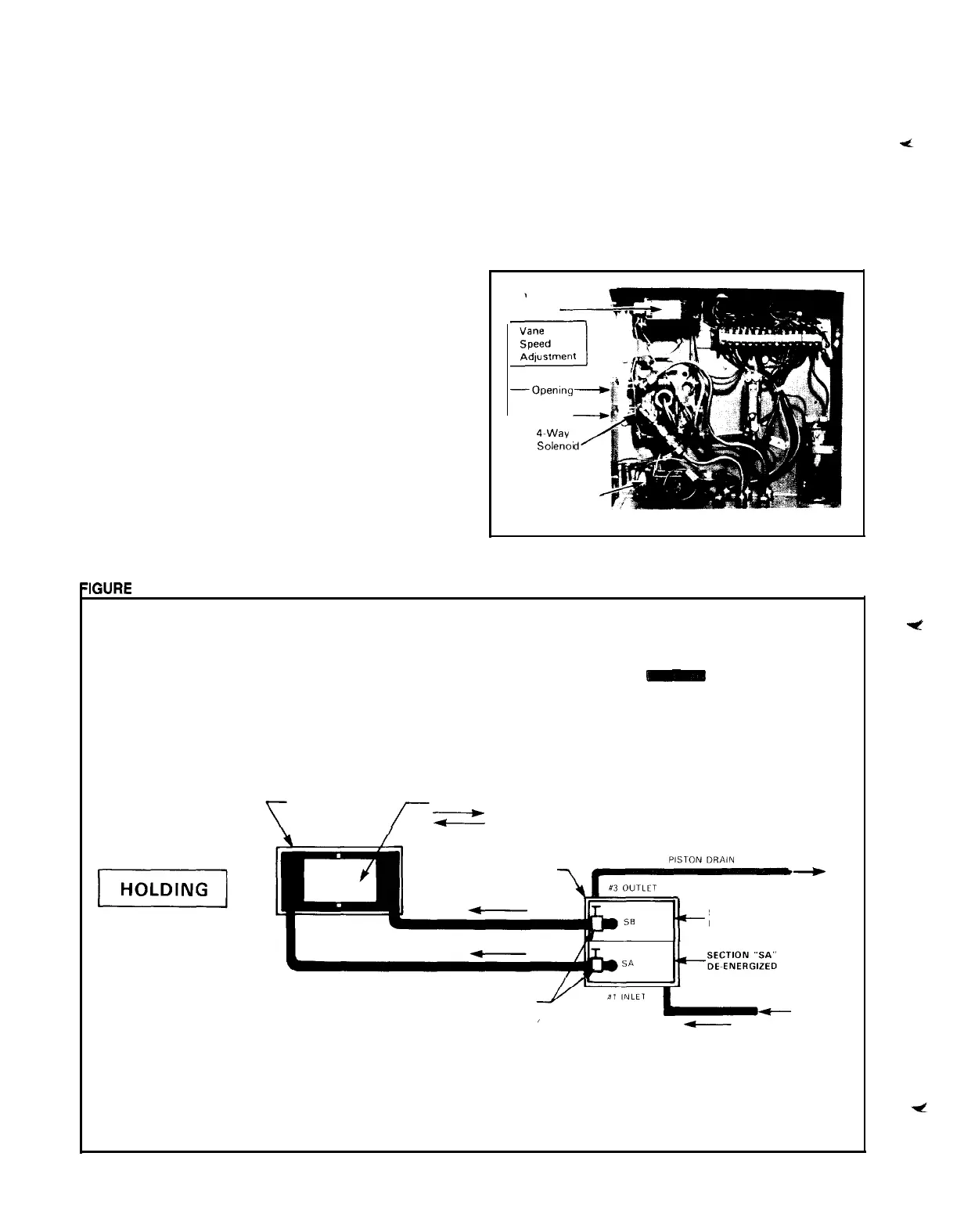

METERING VALVES

The speed at which the capacity control vanes are opened

or closed can be adjusted to suit system operating re-

quirements. Adjustable needle valves in the oil drain lines

are used to control the rate of bleed-off and consequently the

“vane speed”. These needle valves are part of the

4-way

solenoid valve assembly located in the compressor lube box

(Figure 6).

The valves are normally factory set so the vanes will move

from fully closed to fully open in approximately 3 minutes and

from fully open to fully closed in 1 minute (except CE126).

The speed should be slow enough to prevent over-controlling

and hunting. For adjustment procedure, refer to the Ad-

justments section of this manual

FIGURE 6. LUBE BOX

Vane Closed

Switch

)/

,

-0penlng

---+

-Closing

4.Way

Solenoi

Valve

I

Oil Pressure

Differential

-

Switch

IGURE

7. VANE CONTROL SOLENOID OPERATION

-LEGEND-

- Oil Under Pressure

I

Oil Sump Pressure

COMPRESSOR

UNLOADER

CYLINDER

FLOATING

PISTON

LlNKED

TO

INLET

VANES

---p

OPENS VANES

L

CLOSES

VANES

FOUR

WAY

SOLENOID

VALVE

LOCATED IN

LUBE BOX

TO

OIL

+

PUMP

SUMP

SECTION “SB”

DE-ENERGIZED

ADJUSTABLE

NEEDLE VALVES

INTEGRAL

WITH

FOUR WAY

SOLENOID

VAL

VE

FROM OIL

PUMP

DISCHARGE

Page 10

/

IM 307

Loading...

Loading...