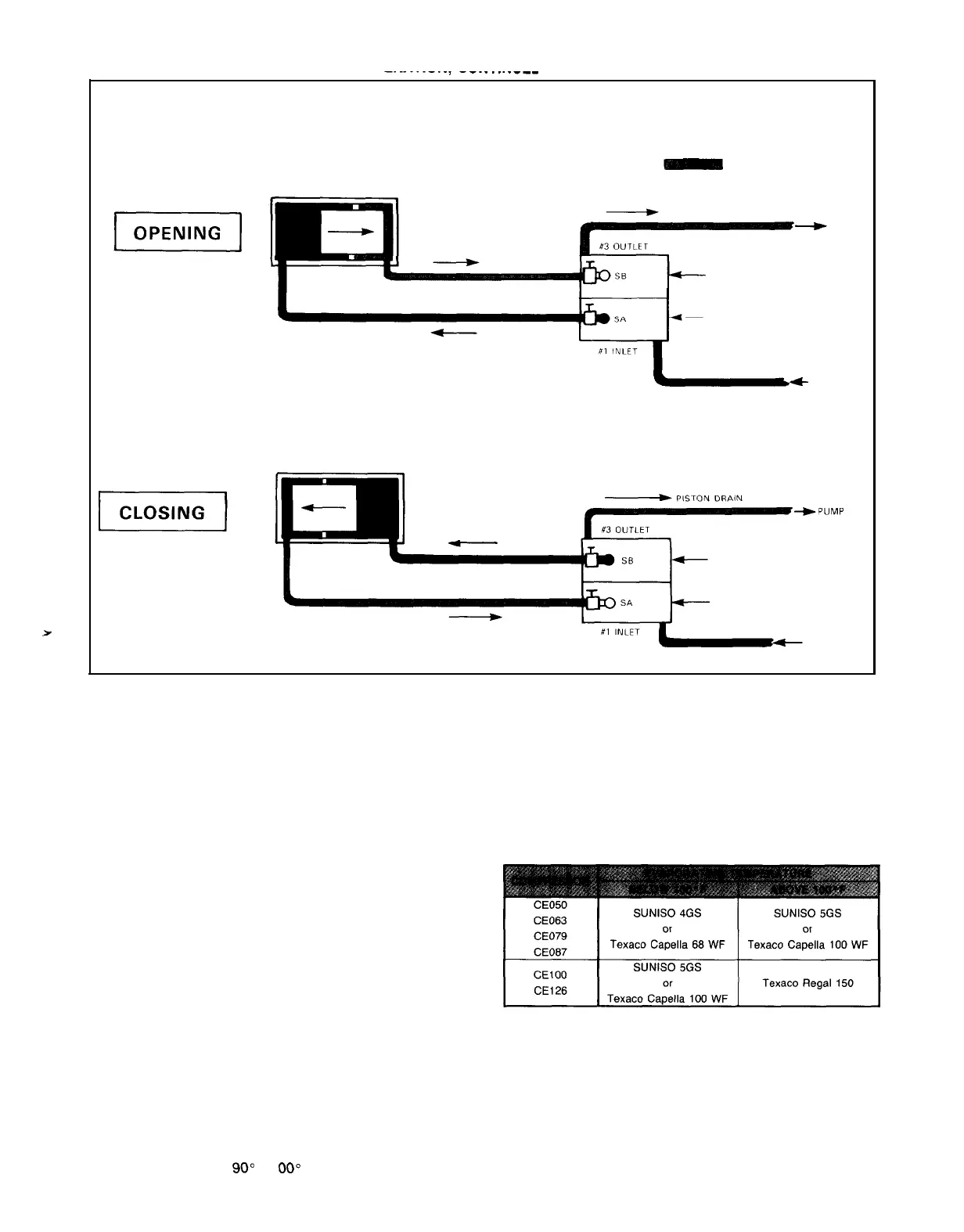

FIGURE 7. VANE CONTROL SOLENOID

OPERATION.

CONTINUED

-LEGEND-

- Oil Under Pressure

Oil Sump Pressure

DRAIN FROM

PISTON

TO OIL

-

PUMP

SUMP

SECTION “SB”

ENERGIZED

SECTION “SA”

DE-ENERGIZED

FROM OIL

c

PUMP

DISCHARGE

TO OIL

*PUMP

SUMP

SECTION

“SB”

DE-ENERGIZED

SECTION

“SA”

ENERGIZED

DRAIN FROM

PISTON

FROM OIL

PUMP

DISCHARGE

OIL SYSTEM

The oil system for the PEH/PHH units provides lubrication

and heat removal for the compressor bearings and internal

parts. In addition, the system provides oil under pressure to

hydraulically operate the piston for positioning the inlet guide

vanes for capacity control.

the oil cooler for optimum operation of the oil system.

Bearings are supplied with oil through internally drilled

passages within the compressor assembly. The oil drains

from the bearings into the gear housing and is gravity returned

to the oil sump.

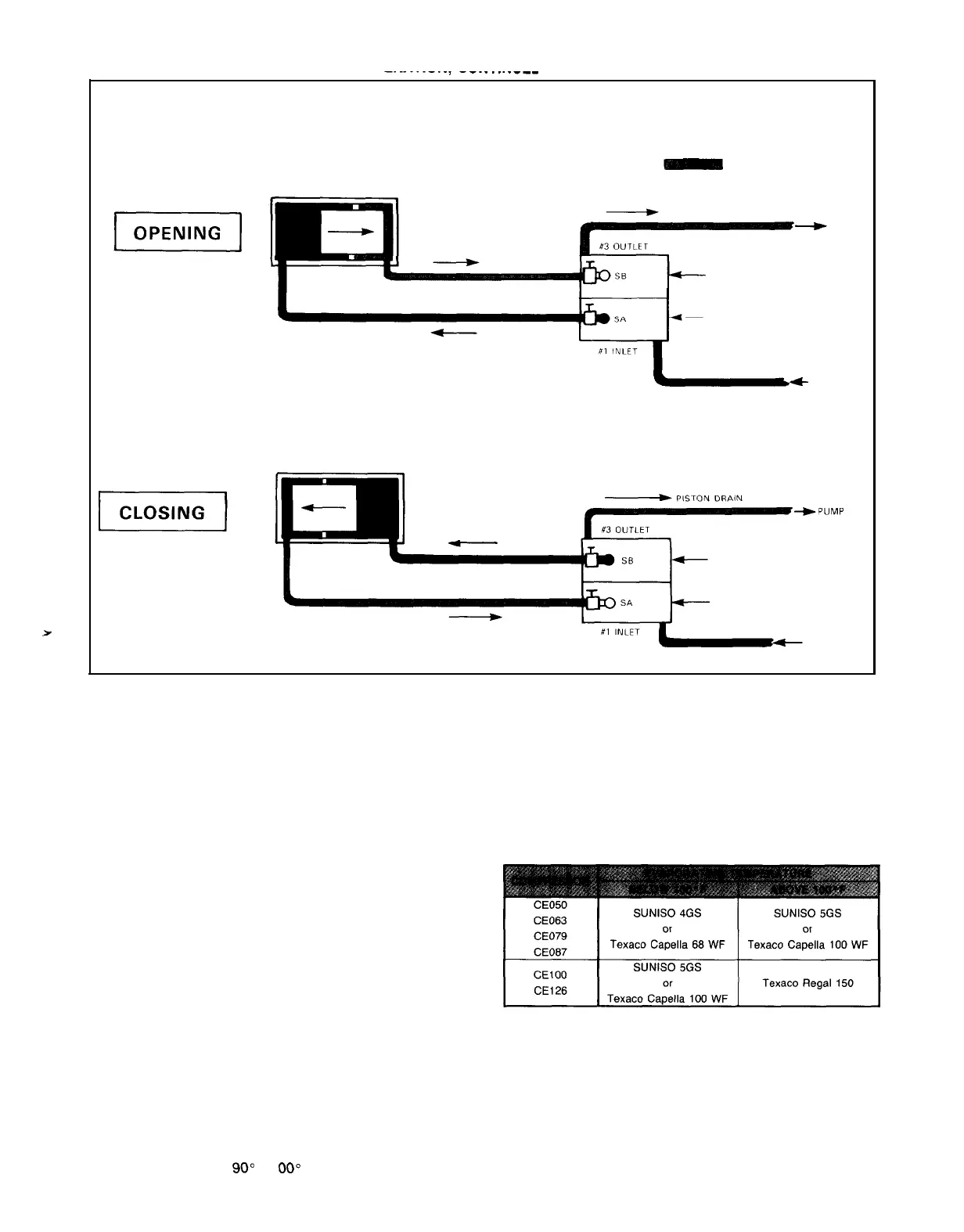

Proper operation of the hydraulic system and bearing

lubrication system can be assured only if McQuay recom-

mended oil is used. For proper oil selection, consult Figure

8. Each unit is factory charged with the proper oil. Under nor-

mal operatioh, no additional oil should be needed.

FIGURE 8. OIL FOR CENTRIFUGAL COMPRESSORS

The oil pump for the CEO50 compressor is completely

self-

contained within the compressor housing. The assembly in-

cludes the pump, pump motor, oil heater and oil separator.

The oil is pumped through the oil discharge line to the oil filter

in the compressor casting and then to the refrigerant-cooled

oil cooler.

The other compressor sizes-CE063, 079, 087, 100 and

126-utilize

a separate oil pump contained in its own oil reser-

voir. This assembly includes pump, motor, heater and oil

separator. Oil is pumped through the discharge line, through

the external oil cooler and then to the oil filter inside the com-

pressor housing. Standard

PEH/PHH 063-126 units utilize

a water-cooled oil cooler although an optional refrigerant-

cooled oil cooler is available.

The oil heaters in the gear case and in the oil pump reser-

voir must remain energized whenever the compressor is off.

IN THE EVENT OF POWER LOSS TO THE HEATERS

ALLOWING THE OIL TO COOL, THE HEATERS SHOULD

BE ENERGIZED FOR 24 HOURS PRIOR TO STARTING

THE COMPRESSOR.

The oil coolers serve to maintain the proper oil temperature

A low oil temperature thermostat (LOT) in the control center

under normal operating conditions. The coolant flow control

prevents the oil pump from starting with cold oil. This ther-

valve should maintain

90” F-l 00” F oil temperature leaving

mostat should be set as high as ambient conditions will allow.

IM 307

/

Page 11

Loading...

Loading...