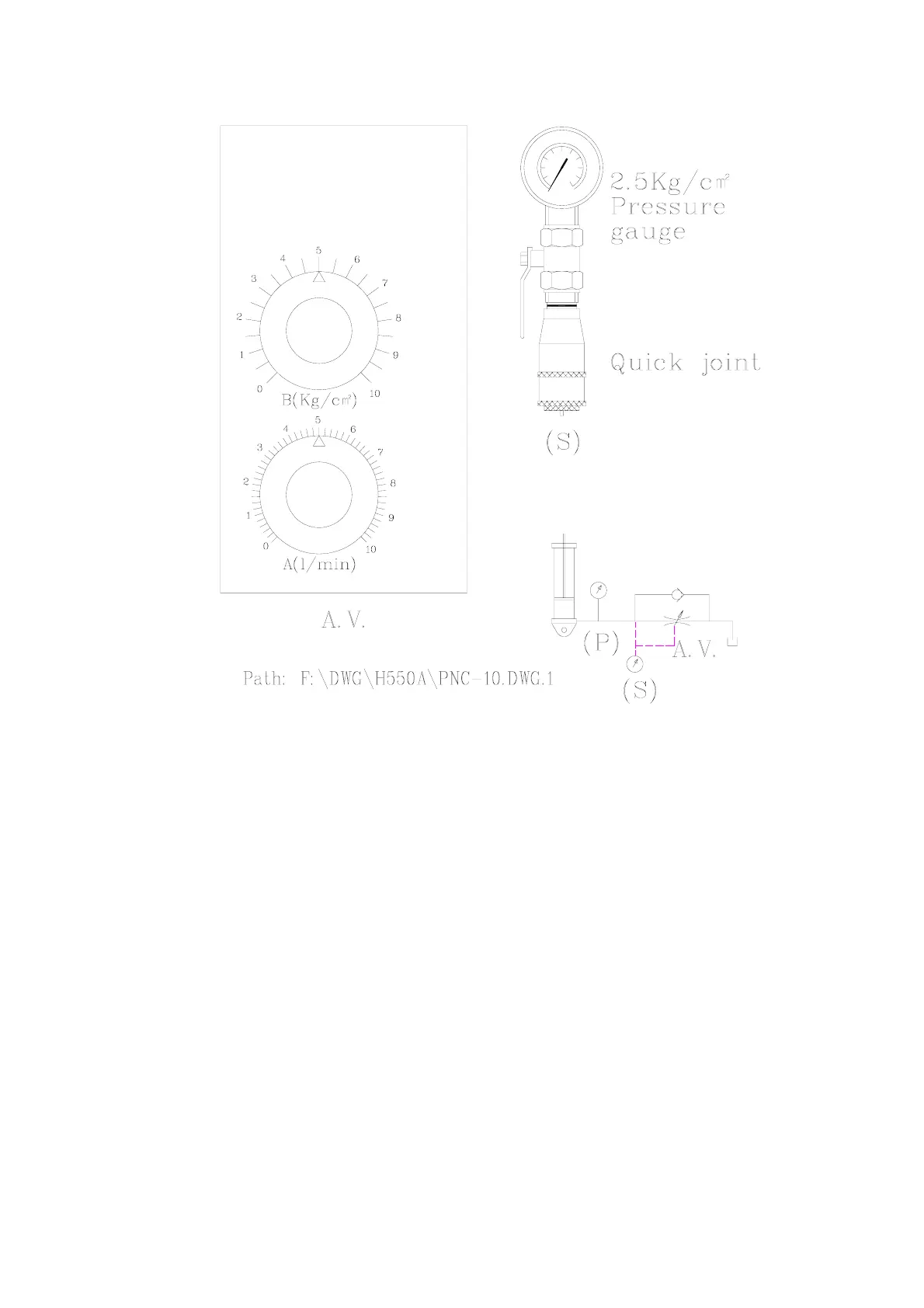

AMPLIFYING VALVE

(1.) THE OUTLINES AND HYDRAULIC CIRCUITS:

(2.) SET-UP

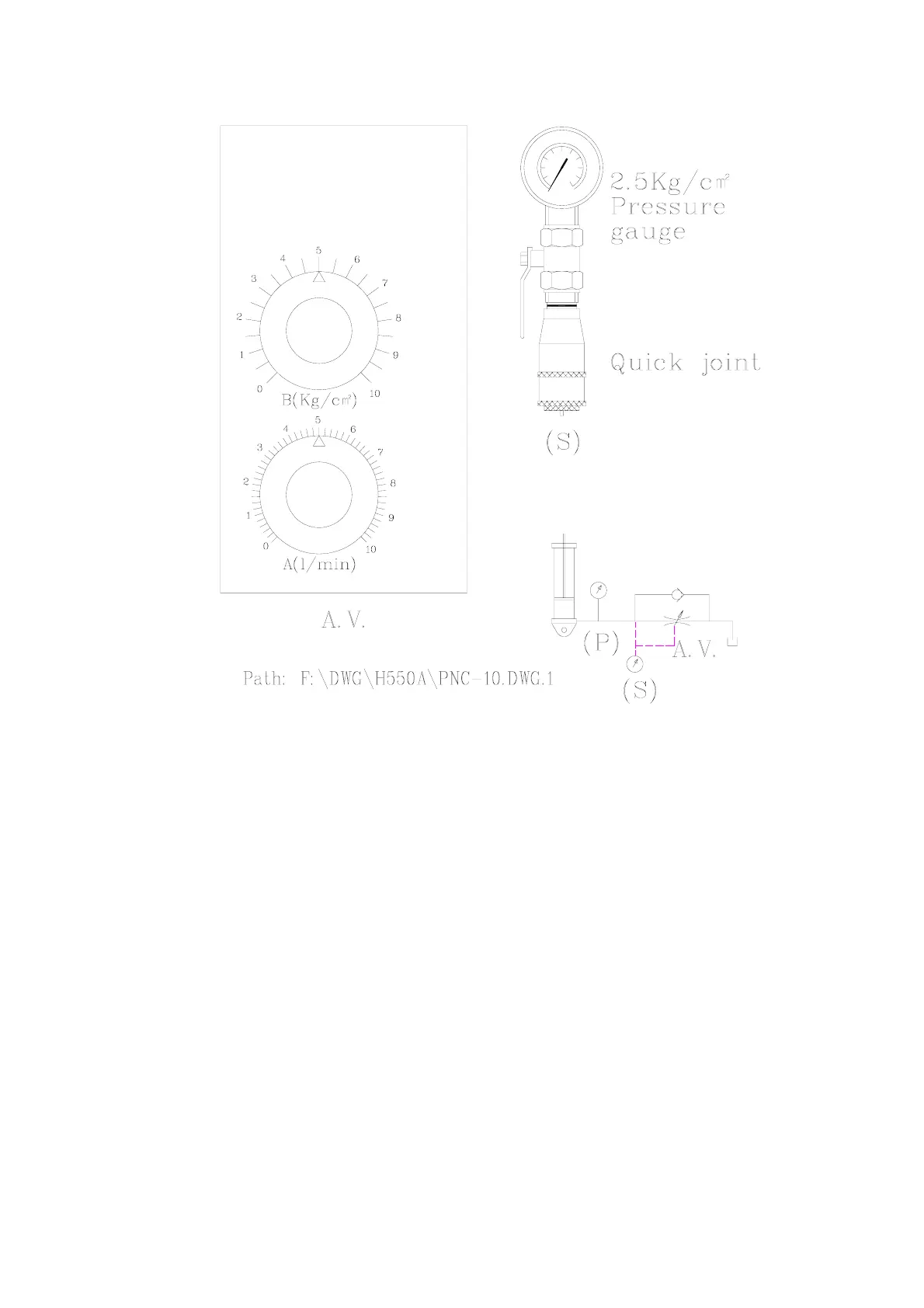

A. The hydraulic pressure indicated in line <p> should be kept in constant during the whole stroke

of the lifting cylinder, i.e. Between the very top and bottom position of the swinging saw frame.

we use springs <r> inside of lifting cylinder to balance/compensate the pressure changes (pressure

varies due to saw frame swinging up and down ) in line <p>. above procedures have been done in

our factory before machine dispatched , now for checking test, please dry run the machine by raising

the saw frame to the very top position and push the saw blade drive button, and having the quick

approach rod lifted (limit switch un-touched), then check the hydraulic pressure in line <p> by

reading the pressure gauge at line <p> to see if the pressure readings keep the same during the whole

stroke.

(maximum 1 kg/sq.cm varies allowed) the pressure reading should be as follows:

8 KG/SQ.CM ............250HAS/300HAS MODELS

10 KG/SQ.CM ............360HAS/400HAS/450HAS MODELS

4 - 6

Loading...

Loading...