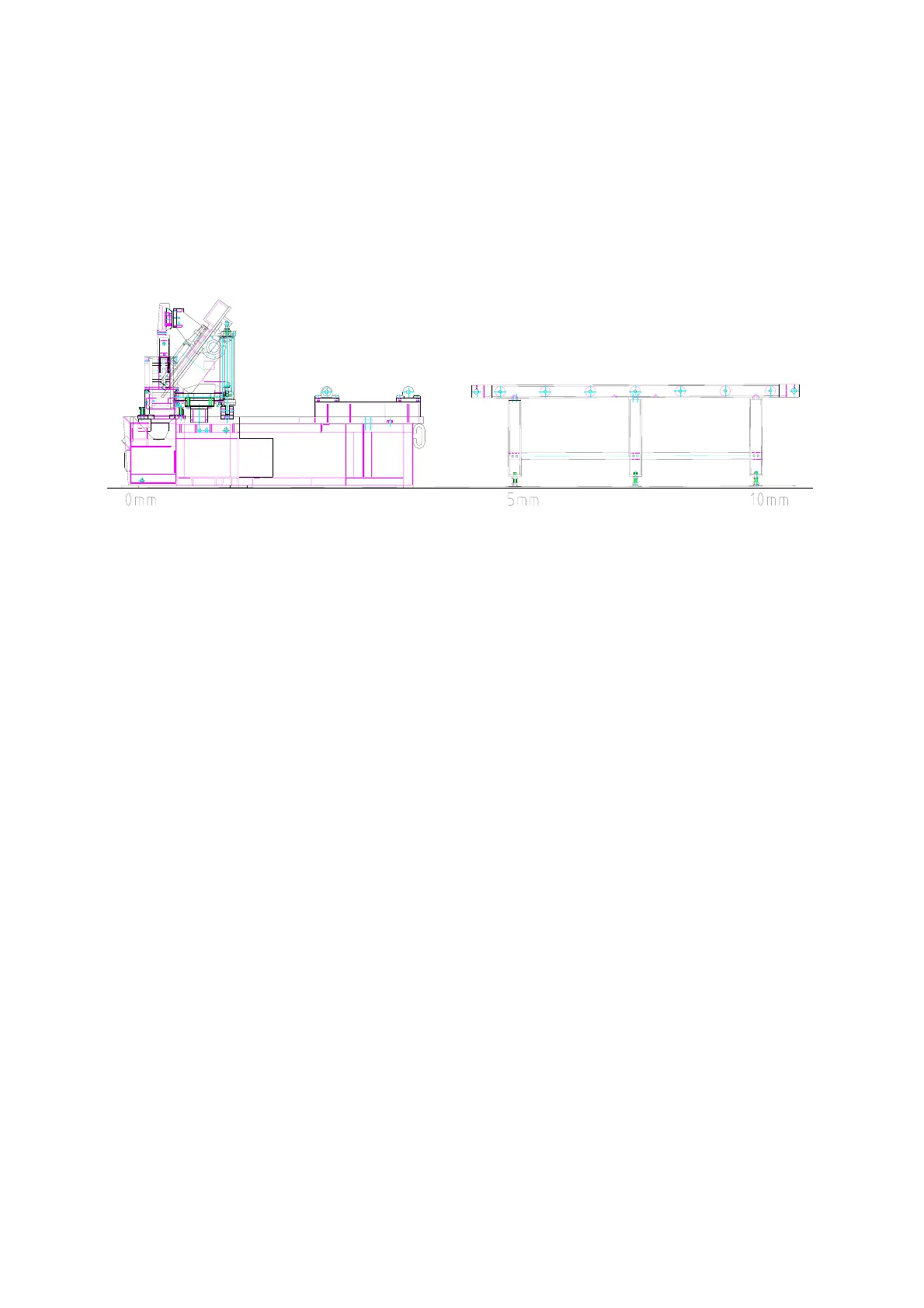

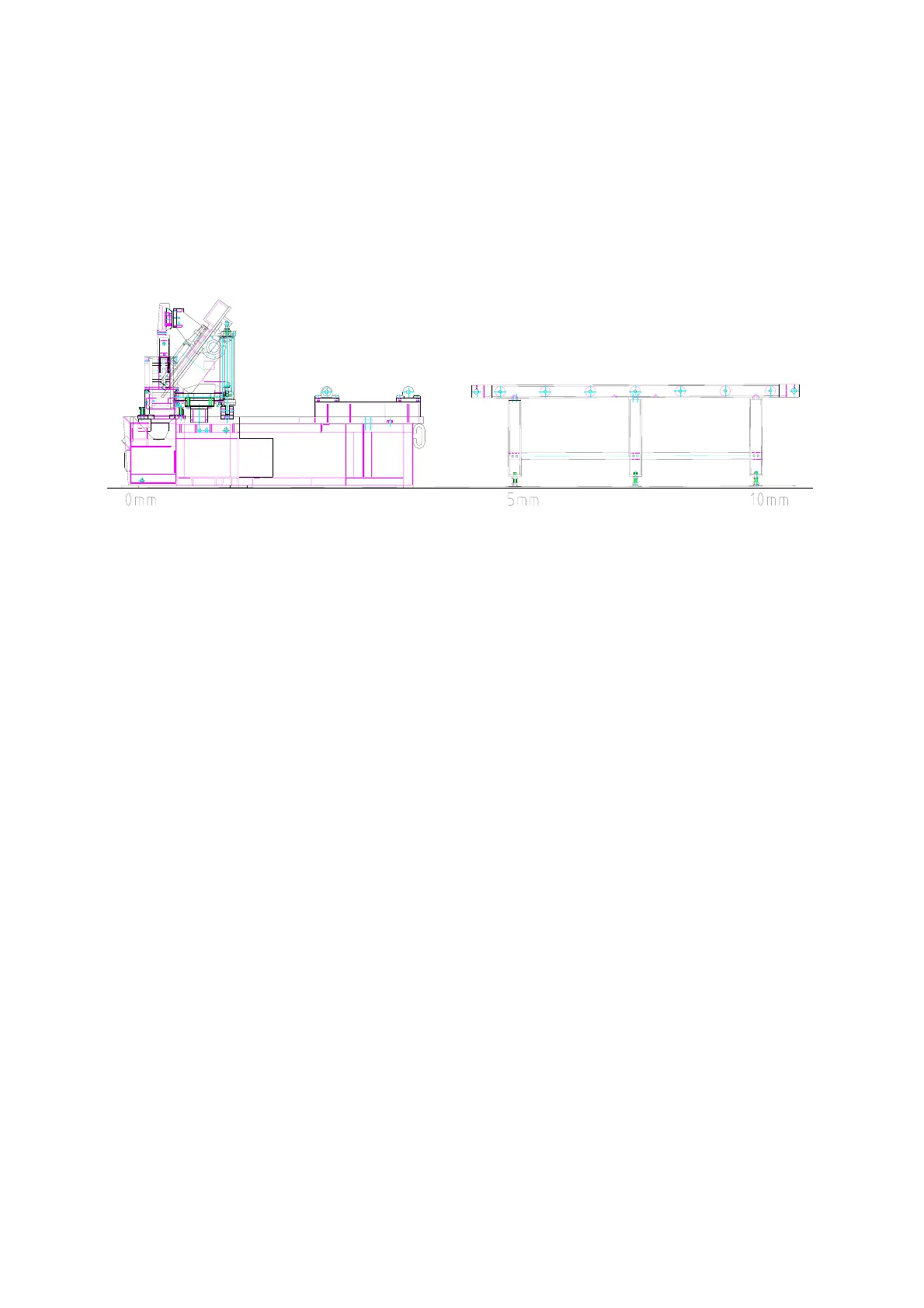

3.2.2 Leveling :

The production accuracy of all precision machinery depends on the accuracy which the machine

is installed . Manufacturing tolerance of the machine can only be guaranteed if the machine is firmly

and properly installed . Once the machine is lowered on the prepared foundation . Machinist levels

should be used alternately on the vice slide plates and the work feed table , and adjust the left-and-

right and fore-and-aft level of the machine with leveling bolt .

Leveling as fig 5 below :

FIG 5

The fore-and-aft level should be adjusted so that the level of the rear end is approximately 10 mm

(3/8" - 1/2") higher than the level of the front end , to provide proper return of the cutting fluid , and

easy operation of car feeding .

The left-and-right level should be adjusted so that the level of the left end is approximately 3 mm

(1/8") higher than the level of the right end , to provide proper return of the cutting fluid , After the

proper leveling position has been obtained anchor the machine with anchor bolts .

Caution : All leveling bolts should support the weight of the machine evenly .

3.2.3 Cleaning and oiling :

After the machine has been placed in position , thoroughly remove its rust preventive coating using

a suitable cleaning solvent and then apply a coat of machine oil . To clean the machine , Kerosene is

preferable to gasoline . It does not evaporate and level dried slushy compound on finished surfaces.

Rags are better than waste as they leave no lint or strings. The machine as received by you. has been

completely drained of all oil. Before any attempt is made to run it .... Before any motor connections

are made .... every detail of the following oiling instruction must be complied with. Refer to the oiling

chart in chapter 7.

Especially , don't forget to fill up the cutting fluid mixture. Usually , the ratio of cutting fluid to

Water should be 1:30 - 1:50. Check the sight gauge to ascertain the fluid level in the tank every day.

Transmission gear box, bar feed gear box, hydraulic oil tank should to topped up monthly. Oil

levels should be strictly observed, for it is of primary importance for proper operation and long lift .

3 - 3

Loading...

Loading...