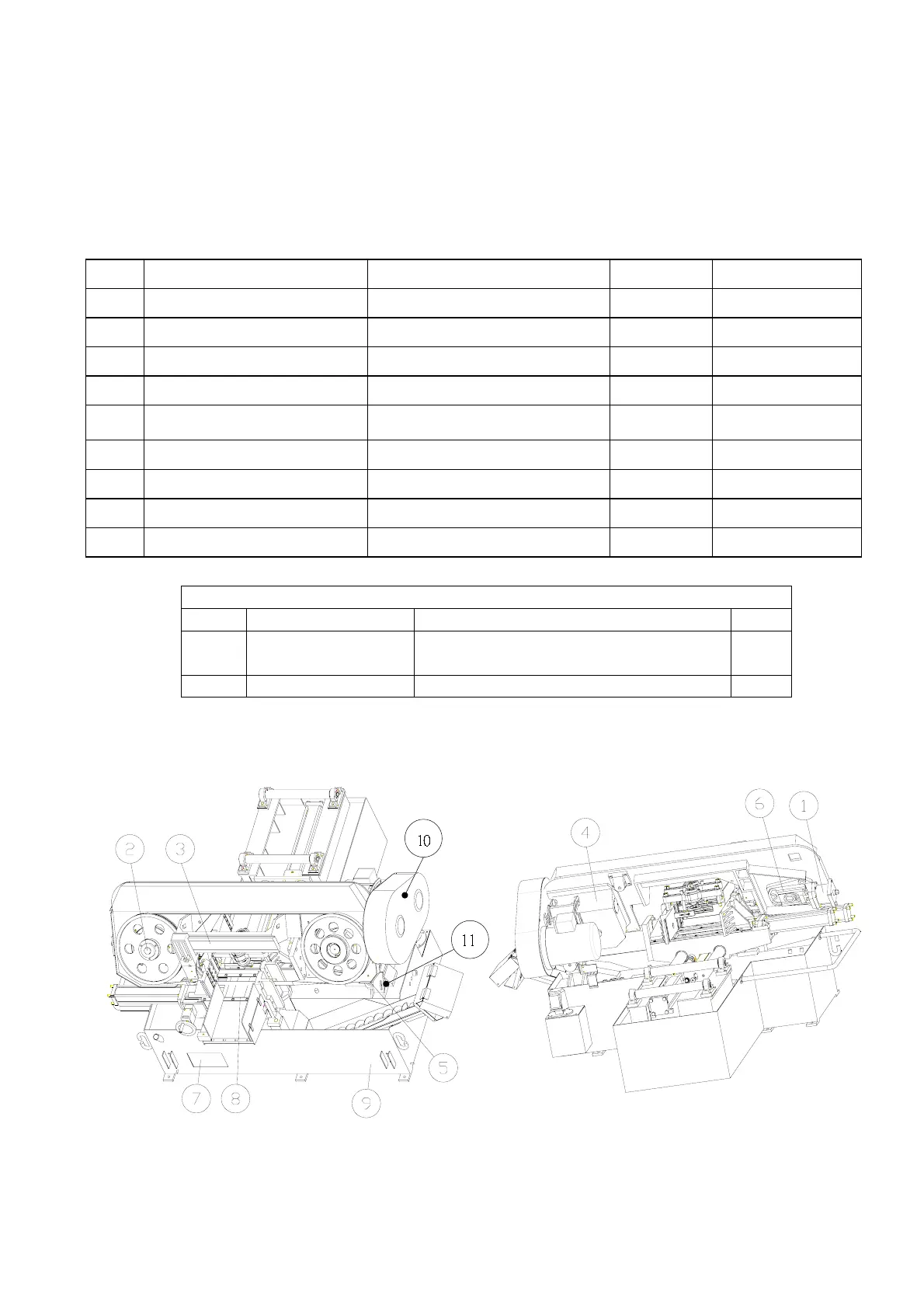

5.2 Oiling and Lubricant

The operator should be responsible for the proper lubrication of the machine. The grade and quality

of lubricant are given in the lubrication chart below :

Oil Lubrication chart

Lubricating Point Lubricant Quantity Oiling Frequency

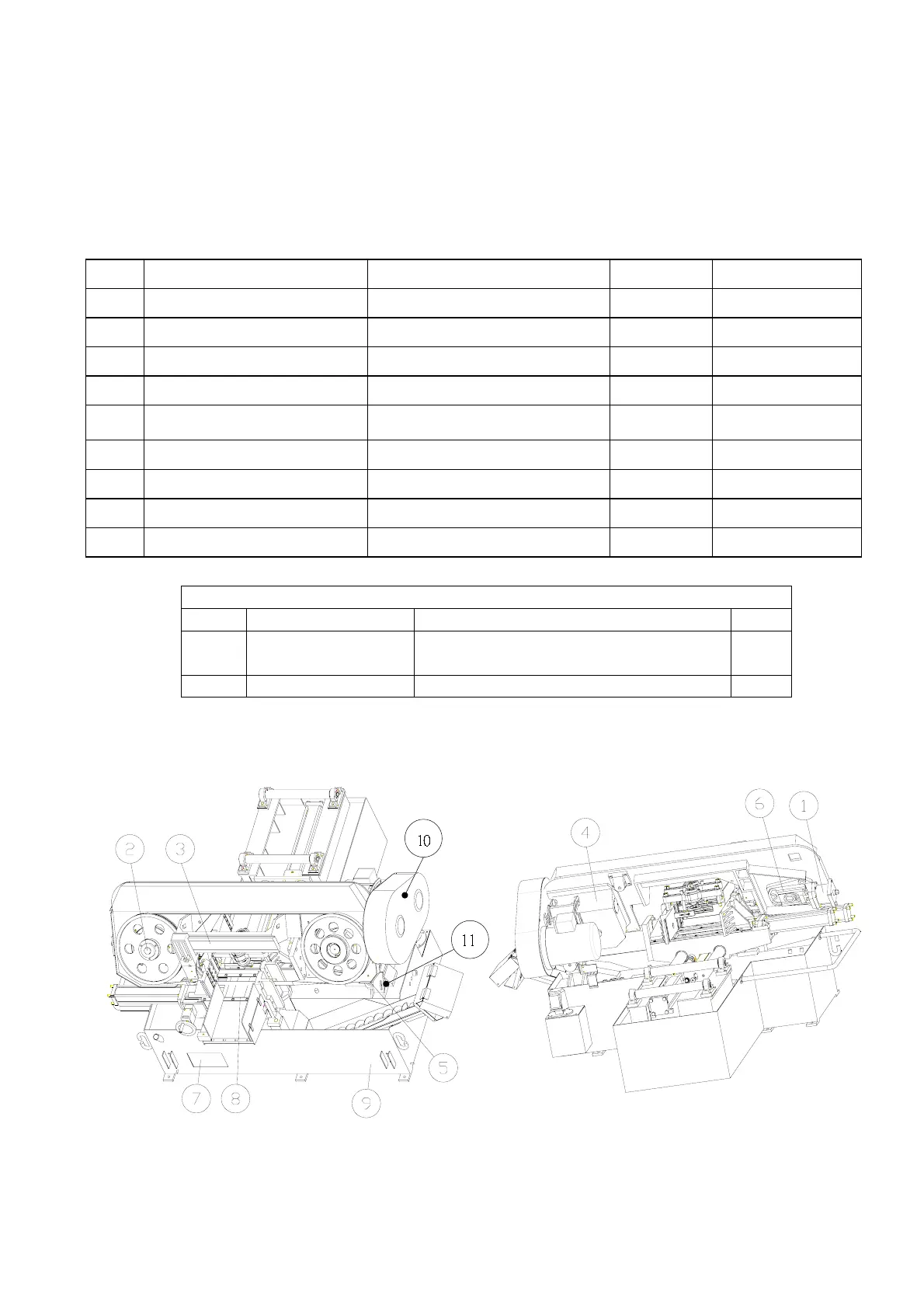

1 Blade Tension Device DAPHNE FLUID 32T few Twice a year

2 Driving Wheel Bearing Grease few Thrice a year

3 Guide Slides DAPHNE FLUID 32T few Oil daily

4 Transmission Gear Box DAPHNE GEAR LUBE 320 3Litres Twice a year

5 Pivot Shaft Grease few Twice a year

6 Adjusting Slide DAPHNE FLUID 32T few Oil daily

7 Hydraulic Oil Tank DAPHNE FLUID 32T 40Litres Twice a year

8 Vise Slides DAPHNE FLUID 32T few Oil daily

9 Cutting Fluid Tank Cutting Oil Mixture 30Litres Daily

Belt Size

NO. Belt Name Belt Size Qty.

10 Motor Belt

50HZ use 3V475& 60HZ use 3V450

Inverter use 3V450

1

11 Wire Brush Belt M43 1

5 - 2

Loading...

Loading...