RIGHT HAND NON-RATCHETING

90-883728 JULY 2001 Page 6A-35

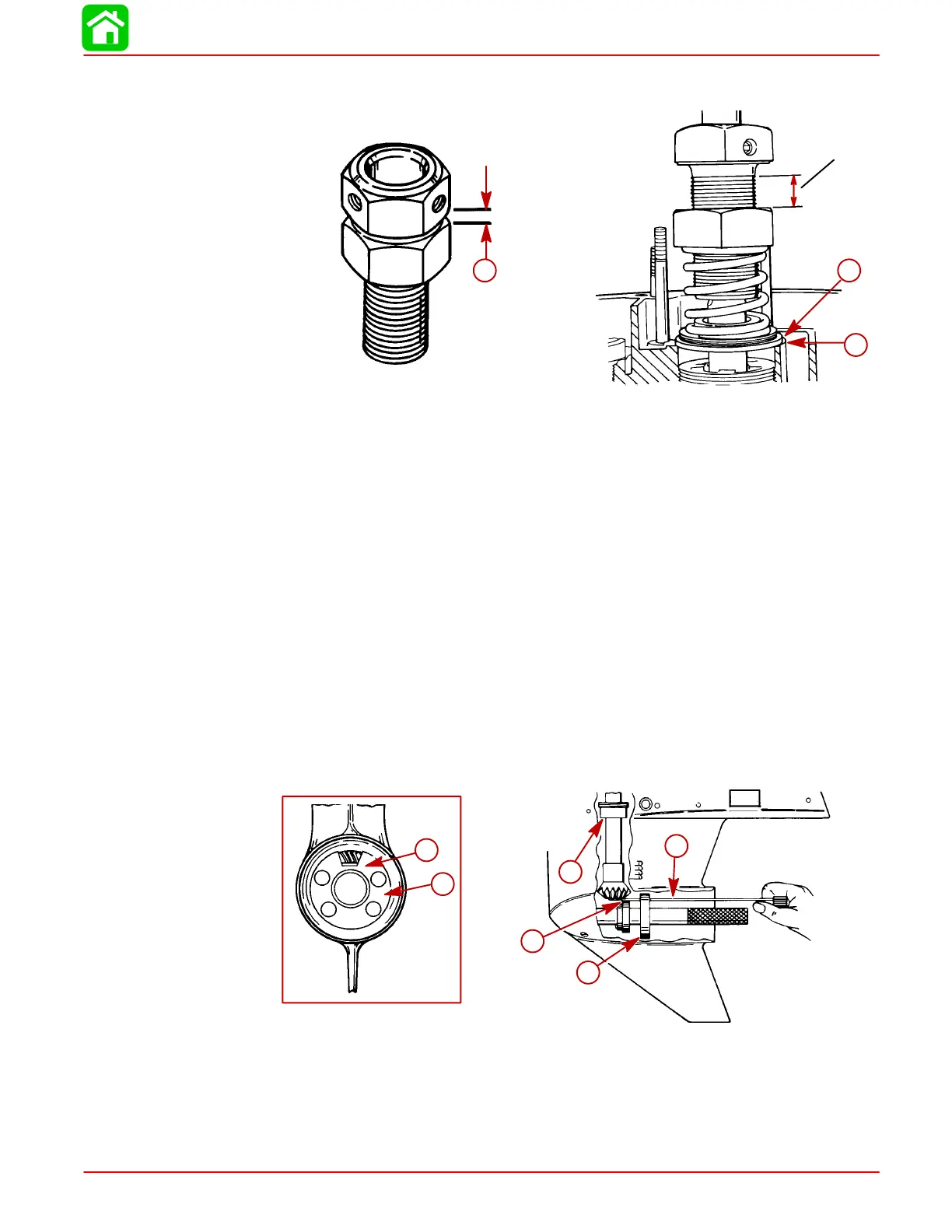

5. Measure distance (a) and increase that distance by 1 in. (25.4 mm) by turning bottom

nut away from top nut.

1 in. (25.4 mm)

a

b

51870

a

b

c

a

a-Distance

b-Adaptor

c-Ledge

6. Turn driveshaft clockwise 2 or more turns to seat driveshaft bearings.

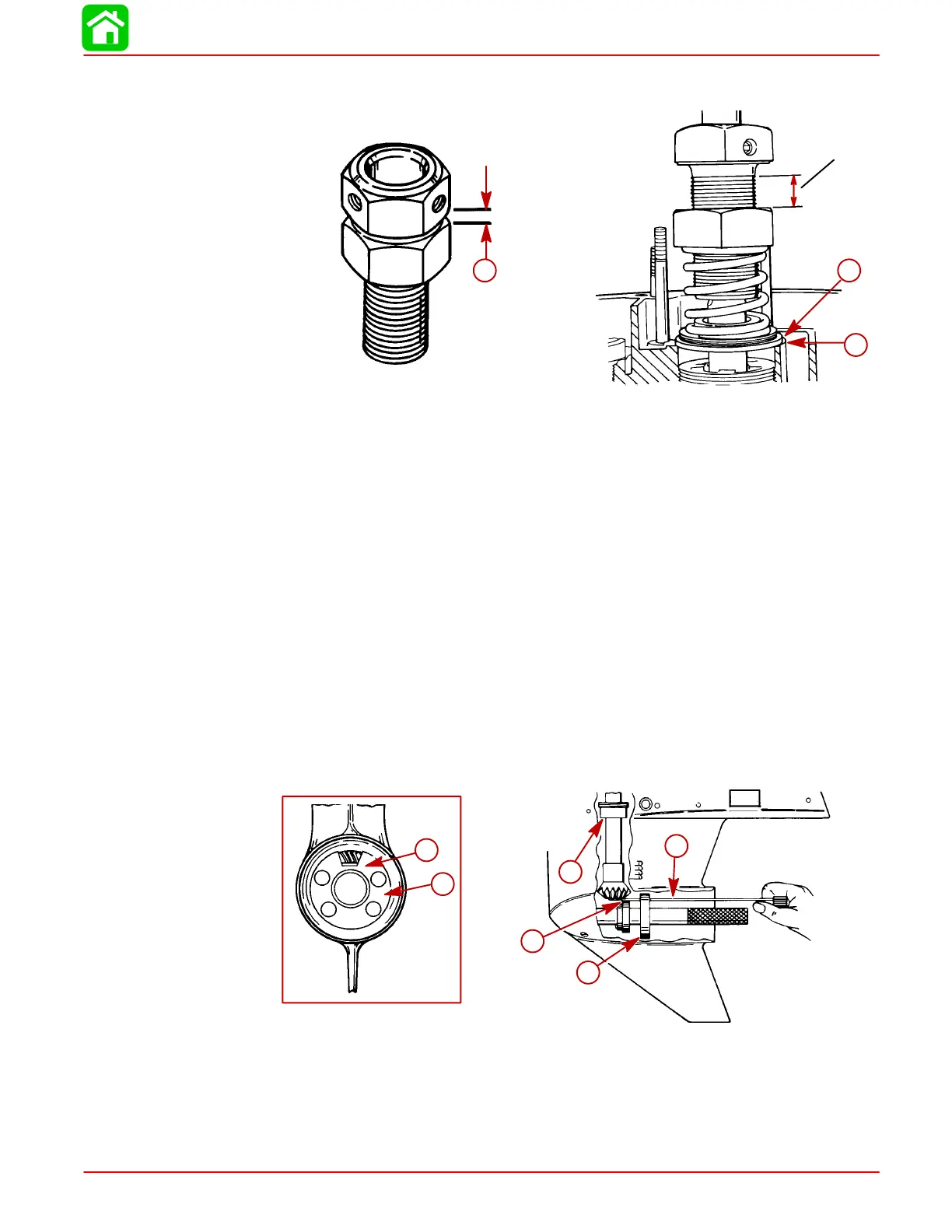

7. Insert Pinion Gear Locating Tool* (91-74776) into gear housing until it bottoms out on

bearing carrier shoulder.

*Pinion Gear Locating Tool (91-12349A2) can be used. Use flat #7 and disc #2. Follow

instructions supplied with tool.

8. Determine pinion gear depth by inserting a feeler gauge thru access slot in pinion gear

shimming tool.

9. Clearance between shimming tool and pinion gear should be 0.025 in. (0.64 mm).

10. If clearance is correct, leave Bearing Preload Tool on driveshaft for “Determining For-

ward Gear Backlash,” following.

11. If clearance is not correct, add (or subtract) shims at location shown to raise (or lower)

pinion gear. When reinstalling pinion nut, apply Loctite 271 on threads of nut and re-

torque pinion nut.

c

a

d

c

a

b

24643

a

b

a

c

c

d

a-Pinion Gear Tool (91-74776 or 91-12349A2)

b-Feeler Gauge

c-Obtain 0.025

in. (0.64 mm) Clearance between Shimming Tool and Pinion

Gear

d-Add or Subtract Shim(s) Here

Loading...

Loading...