22

90-10183R30

GB

oh

MAINTENANCE

ohn1

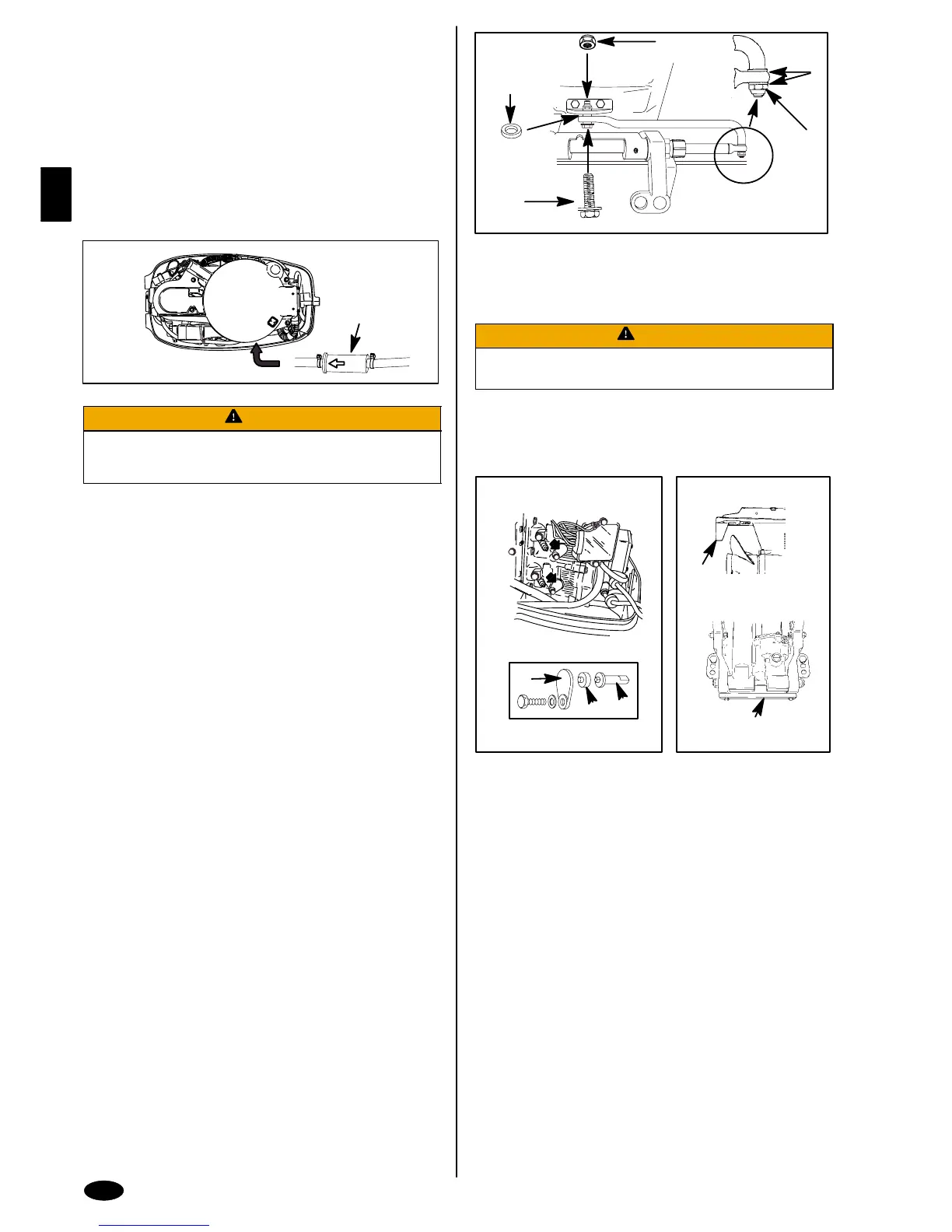

BATTERY INSPECTION

The battery should be inspected at periodic intervals to ensure proper engine

starting capability.

IMPORTANT: Read the safety and maintenance instructions which

accompany your battery.

1. Turn off the engine before servicing the battery.

2. Add water as necessary to keep the battery full.

3. Make sure the battery is secure against movement.

4. Battery cable terminals should be clean, tight, and correctly installed. Positive

to positive and negative to negative.

5. Make sure the battery is equipped with a nonconductive shield to prevent

accidental shorting of battery terminals.

goh90

1

ohh3

FUEL SYSTEM

WARNING

Avoid serious injury or death from gasoline fire or explosion. Carefully

follow all fuel system service instructions. Always stop the engine and

DO NOT smoke or allow open flames or sparks in the area while servicing

any part of the fuel system.

Before servicing any part of the fuel system, stop engine and disconnect the

battery. Drain the fuel system completely. Use an approved container to collect

and store fuel. Wipe up any spillage immediately. Material used to contain spillage

must be disposed of in an approved receptacle. Any fuel system service must be

performed in a well ventilated area. Inspect any completed service work for signs

of fuel leakage.

Fuel Line Filter

1 Inspect the fuel line filter. If the filter appears to be contaminated, remove and

replace.

IMPORTANT: Visually inspect for fuel leakage from the filter connections by

squeezing the primer bulb until firm, forcing fuel into the filter.

Fuel Line Inspection

Visually inspect the fuel line and primer bulb for cracks, swelling, leaks, hardness,

or other signs of deterioration or damage. If any of these conditions are found, the

fuel line or primer bulb must be replaced.

goh91

a

c

b

d

e

ohi2

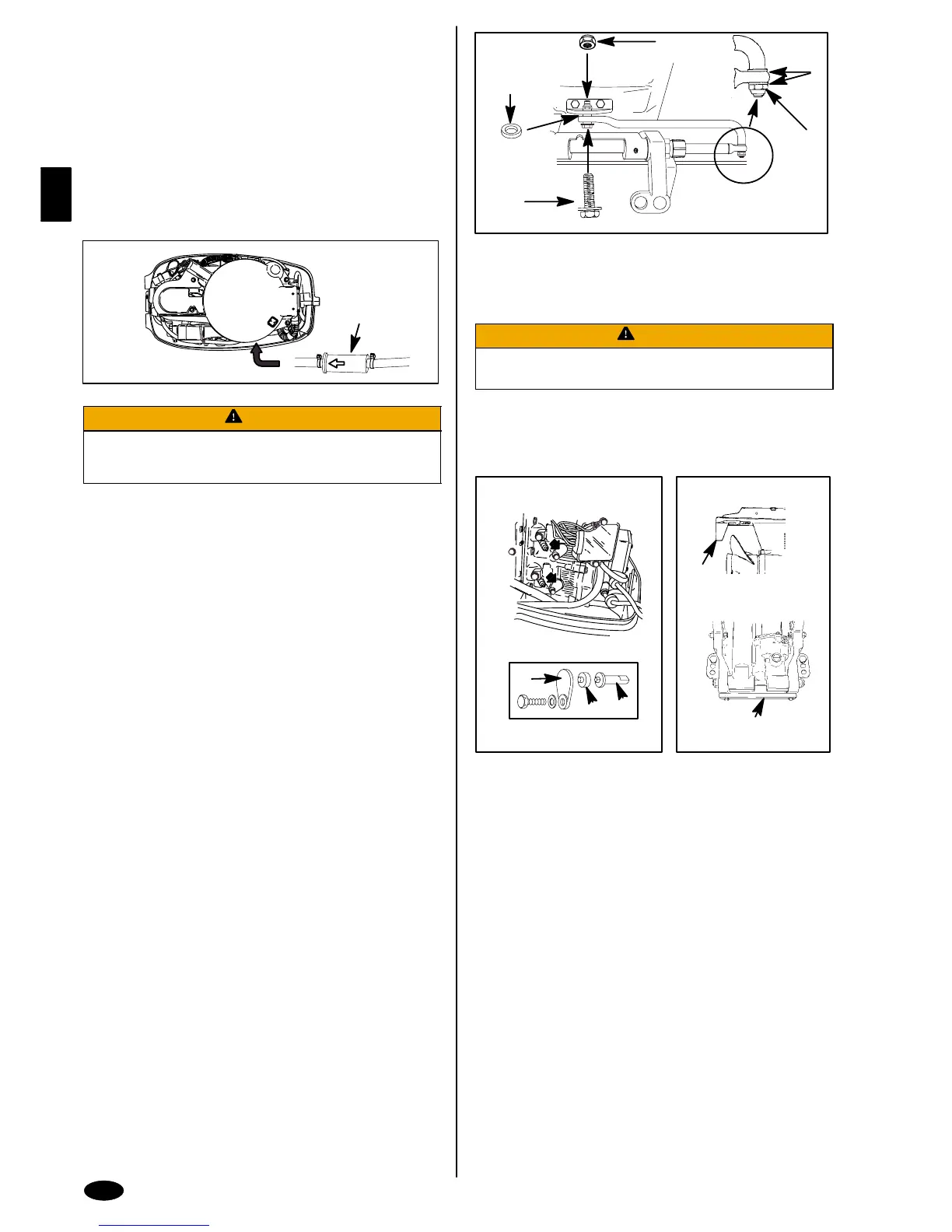

STEERING LINK ROD FASTENERS

IMPORTANT: The steering link rod that connects the steering cable to the

engine must be fastened using special washer head bolt (“a” – Part Number

10-90041) and self locking nylon insert locknuts (“b” & “c” – Part Number

11-34863). These locknuts must never be replaced with common nuts (non

locking) as they will work loose and vibrate off, freeing the link rod to

disengage.

WARNING

Disengagement of a steering link rod can result in the boat taking a full,

sudden, sharp turn. This potentially violent action can cause occupants

to be thrown overboard exposing them to serious injury or death.

Assemble steering link rod to steering cable with two flat washers (d) and nylon

insert locknut (“b” – Part Number 11-34863). Tighten locknut (b) until it seats, then

back nut off 1/4 turn.

Assemble steering link rod to engine with special washer head bolt (“a” – Part

Number 10-90041), locknut (“c” – Part Number 11-34863) and spacer (“e” –

12-71970). First torque bolt (a) to 20 lb. ft. (27 N·m), then torque locknut (c) to 20

lb. ft. (27 N·m).

goh92

1

2

c

b

a

d

e

ohk13

CORROSION CONTROL ANODE

Your outboard will have three or four corrosion control anodes. An anode helps

protect the outboard against galvanic corrosion by sacrificing its metal to be slowly

eroded instead of the outboard metals.

Each anode requires periodic inspection especially in salt water which will

accelerate the erosion. To maintain this corrosion protection, always replace the

anode before it is completely eroded. Never paint or apply a protective coating on

the anode as this will reduce effectiveness of the anode.

1 Two anodes (c) are installed in the engine block. Remove anodes at locations

shown. Install each anode with rubber seal (b) and cover (a). Tighten bolts to

70 lb. in. (8 N·m) torque.

2 A third anode is the trim tab (d), and models which have the longer type of

transom brackets will have a forth anode installed (e).

Loading...

Loading...