Powerhead

90-8M0065421 NOVEMBER 2012 Page 4A-29

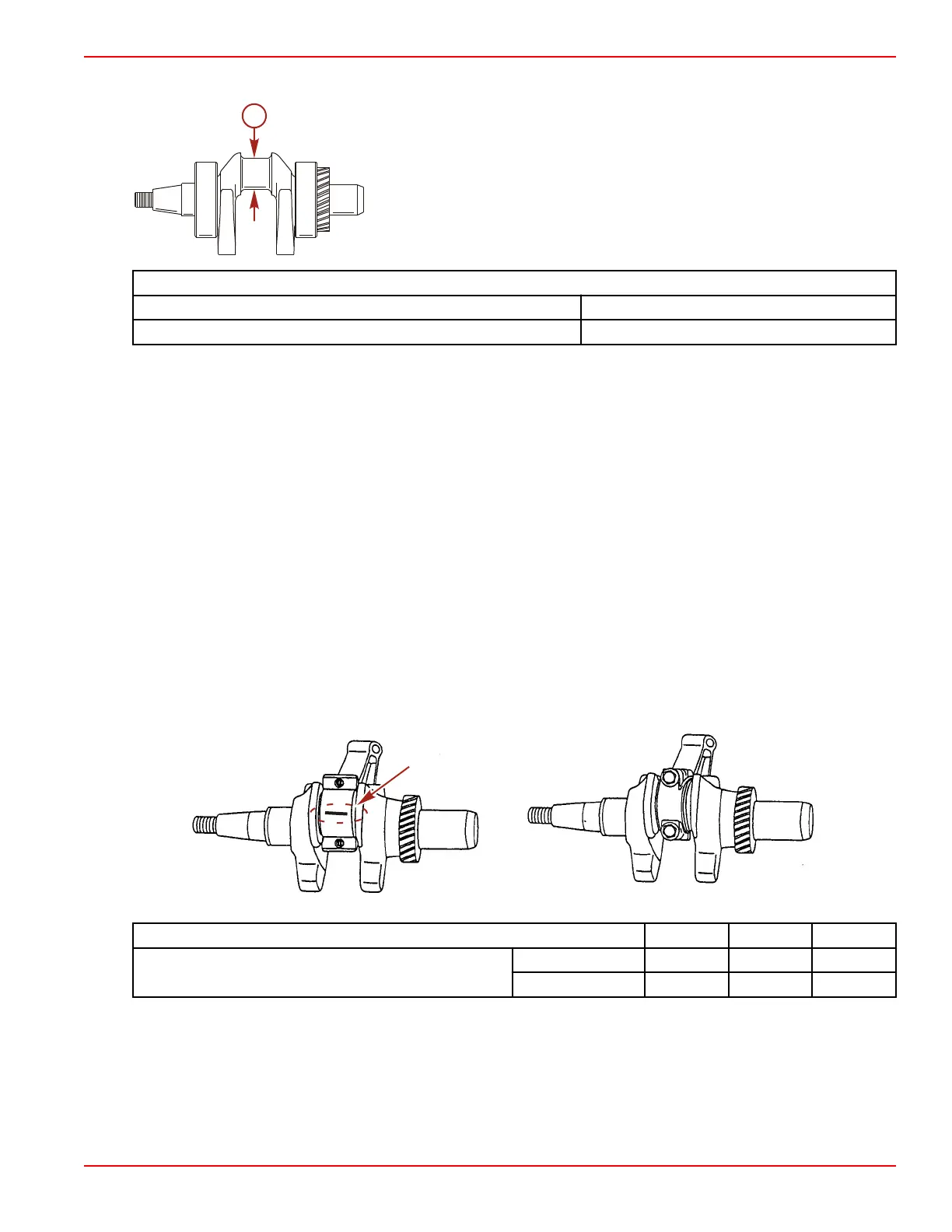

2. Replace the crankshaft if the journal is out of specification.

a - Crankpin journal diameter

Crankshaft Bearing Journal

Crankpin journal (standard) 19.98 mm (0.7866 in.)

Crankpin journal (service limit) 19.95 mm (0.7854 in.)

Crankshaft Bearings

1. Inspect the crankshaft bearings for:

• Rusted balls or races

• Fractured ring

• Worn or galled surfaces

• Badly discolored balls or races

• General feeling of roughness

2. Replace the upper crankshaft bearing if defective.

3. Replace the crankshaft if the lower bearing is defective.

NOTE: The lower crankshaft bearing is not serviceable.

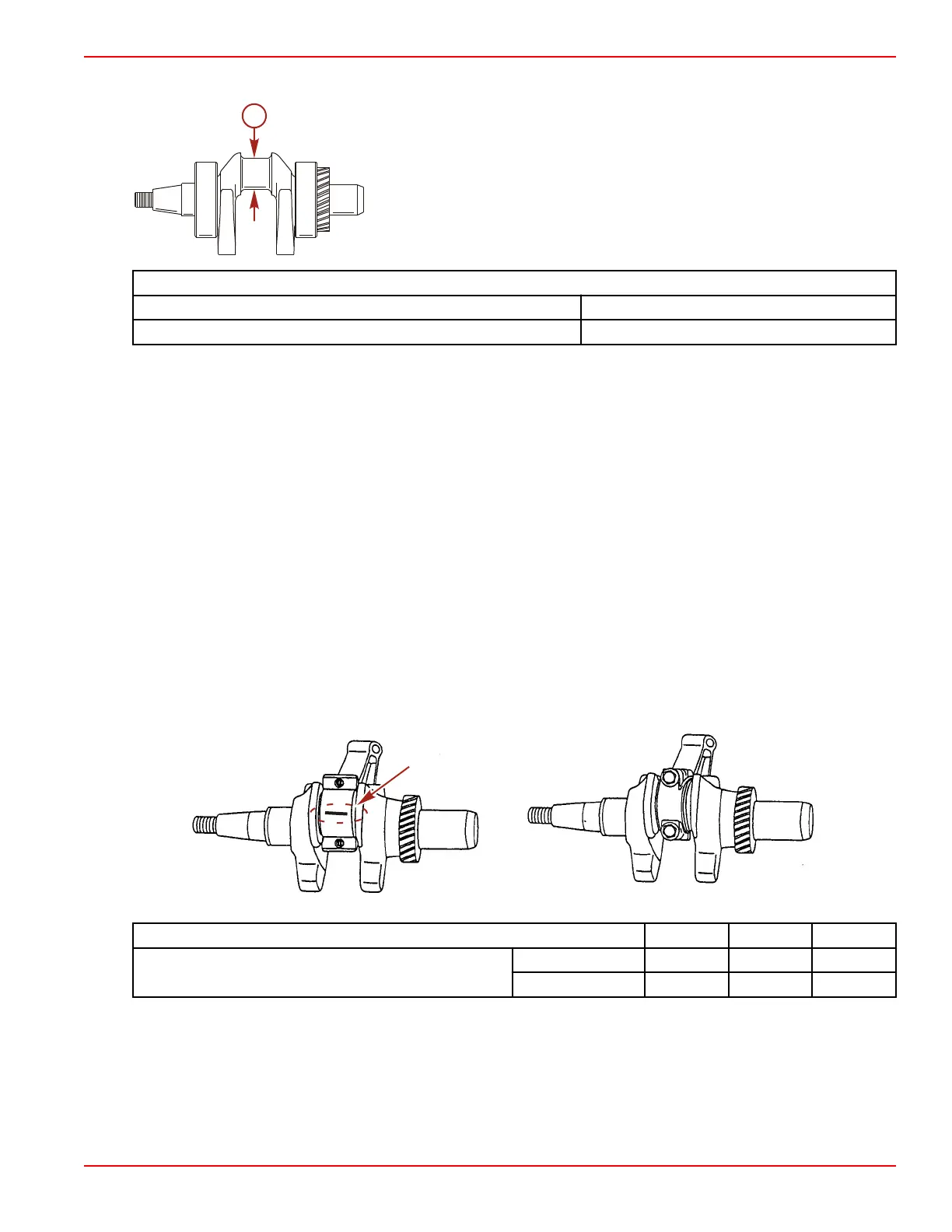

Measuring Crankpin Oil Clearance

1. Clean the oil from the connecting rod bearing surface and connecting rod crankshaft journal.

2. Install the connecting rod onto the crankshaft.

IMPORTANT: Make sure the "UP" mark on the connecting rod faces towards the flywheel end of the crankshaft.

3. Place a piece of plastigauge on the crankpin journal.

4. Install the connecting rod cap and tighten the connecting rod cap screws to the specified torque.

IMPORTANT: Do not rotate crankshaft while performing this measurement.

Description

Nm lb‑in. lb‑ft

Connecting rod cap screw

First

6 53

Final

11 97

5. Remove the connecting rod cap.

Loading...

Loading...