Powerhead

Page 4A-18 90-8M0065421 NOVEMBER 2012

Description Nm lb‑in. lb‑ft

Fuel tank mounting bolts (M6 x 25) (3) 6 53

Valve Clearance Adjustment

IMPORTANT: Adjust the valve clearance while the engine temperature is cool.

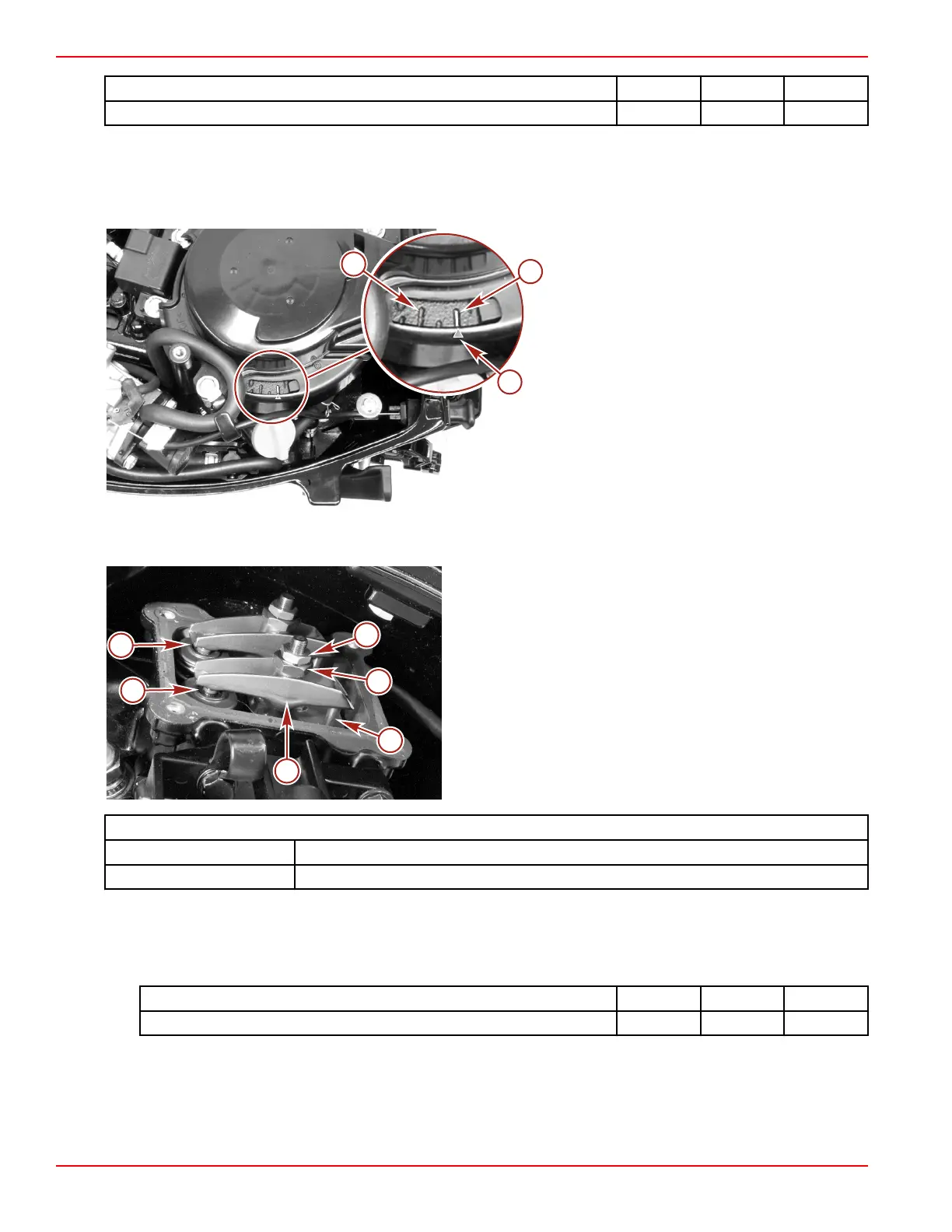

1. Align the timing mark on the flywheel to 0° TDC on the compression stroke. The piston is at top dead center and both

valves are closed. The valve clearance may now be checked.

a - 0° flywheel timing mark

b - Pointer on flywheel cover

c - 10° BTDC flywheel timing mark

2. Remove the spark plug lead and the cylinder head cover.

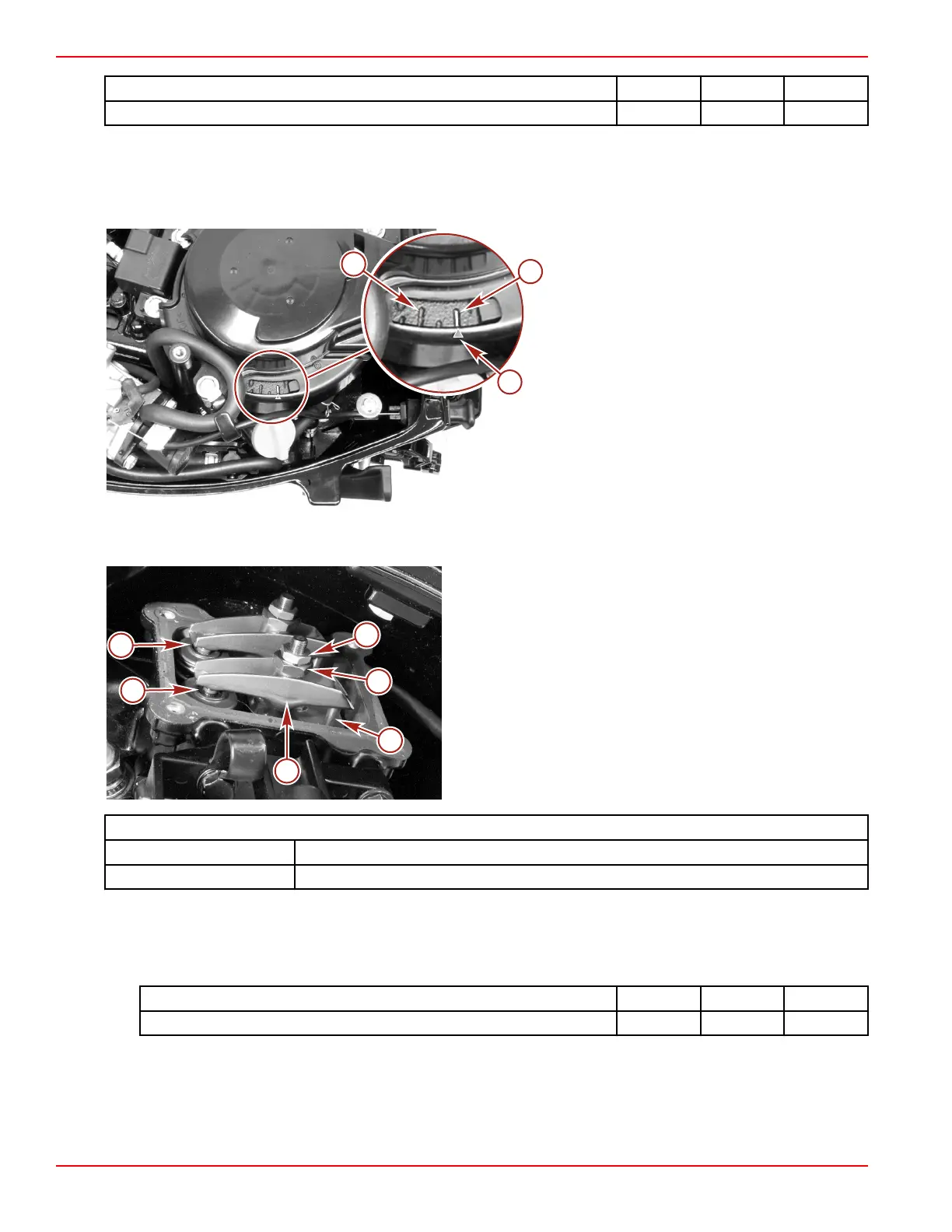

3. Measure each valve clearance with a feeler gauge.

a - Nut

b - Pivot

c - Push rod

d - Rocker arm

e - Intake valve

f - Exhaust valve

Valve to Rocker Arm Clearance

Intake 0.06–0.14 mm (0.0024–0.0055 in.)

Exhaust 0.11–0.19 mm (0.0043–0.0075 in.)

4. Adjust if out of specification.

a. Hold the pivot and loosen the nut.

b. Adjust valve clearance by rotating the pivot.

c. When the proper clearance is achieved, hold the pivot and tighten the nut to the specified torque.

Description

Nm lb‑in. lb‑ft

Rocker arm nut 11 97

d. Recheck valve clearance.

5. Clean the cylinder head and cover surface.

6. Install a new gasket.

7. Attach the cylinder head cover to the cylinder block with four bolts. Tighten the bolts to the specified torque.

Loading...

Loading...